Norwegian drilling contractors Seadrill and Odfjell have signed up for three GVA 7500 semi-submersibles, a new design by GVA Consultants for ultra-deepwater, harsh environments. Negotiations are also advanced with another contractor for a fourth GVA 7500 rig, according to Robert Ludwigson, GVA Consultants’ vice president for business development.

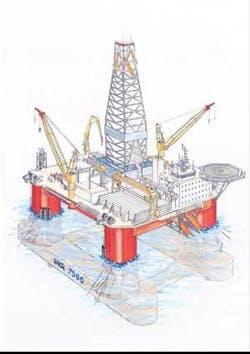

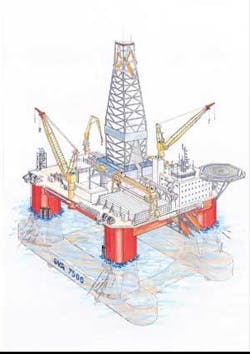

Computer image of theGVA 7500 drilling semi, designed for harsh environment, deepwater operations.

The one Odfjell and two Seadrill rigs will be built by Daewoo Shipbuilding and Marine Engineering in Korea. The principle difference between the deliveries relates to the scope of offline activity, says Ludwigson: Seadrill has selected the one-and-a-half derrick option, while Odfjell will have a dual derrick. Each has its own merits: the one-and-a-half derrick design allows the 20in. casing string to be assembled while the tophole is being drilled. The dual derrick allows build-up of the riser in parallel with drilling.

These extra capabilities bring savings in operating time, but also add to the capital outlay, so it is up to each owner to assess the merits of the two options. There are also patents related to dual derrick operations which have to be taken into account.

The GVA 7500 is GVA Consultants’ sixth generation design, developed to provide a cost-effective solution for drilling in extreme conditions of water depth and climate. It is rated for operations in water depths of 10,000 ft and in Beaufort 10 sea states. To provide the necessary clearance over the sea surface for operating in harsh environments, the design has a large air gap - 17.5 m. In addition to complying with all relevant regulatory requirements concerning stability, the GVA 7500 incorporates a deck box - a basic design principle to be found in all the company’s semisub concepts, which makes a significant contribution to residual stability in extreme emergencies.

For station-keeping in deep waters the design incorporates DP3 dynamic positioning capability, using eight 3.8 MW thrusters. There is also a chain mooring system for use in water depths up to 500m, or in conjunction with pre-set moorings, commonly applied in the deepwater Gulf of Mexico.

For operations in deep waters and often, by extension, in remote locations, a large load capacity is needed to maximize logistical autonomy. The GVA 7500 has a variable deckload of up to 8,200 tonnes, the largest of any sixth-generation design, according to Ludwigson. The deck dimensions are 110 m x 78 m. Operating draft is 23 m and operating displacement 51,500 tonnes.

Deck layout and pipe-handling capacity has been tailored to accommodate operations with 90-ft riser joints rather than 75-ft, as this means fewer connections are required to make up the riser. The riser joints are stored horizontally, and handled by a gantry crane.

There are four separated engine-rooms, providing maximum redundancy and separation. Power is supplied by eight 5 MW diesel generators.

The design is rated for drilling depths of 40,000 ft in the subsurface. Drilling equipment includes a hook-load of 1,000 tons and topdrive system. An 18-3/4in, 15,000psi BOP stack is specified to permit operations in extreme downhole conditions, with high pressures and temperatures.

The GVA 7500 design complies with the latest regulatory requirements in Norway, the UK and the US, and with Norsok guidelines on safety and work environment. Accommodation is provided for 158 personnel, or 128 in the Norwegian sector.

There is good flexibility within the main framework of the design, Ludwigson stresses. “Different drilling contractors have different preferences, especially with respect to drilling equipment selection,” he says. “We were concerned to ensure that the design allows them to incorporate their preferences.”

Advances for mild environments

While much of the industry’s attention has focused on extending the operating envelope of drilling rigs into ever harsher environments, GVA Consultants is also seeing interest for rigs suited to ultra-deep waters in mild environments, typically offshore Brazil, West Africa, South-East Asia and the Gulf of Mexico. For such conditions the company has developed the GVA 7000.

This concept builds on the company’s proven GVA 4500 design; two drilling rigs built to this design were delivered to Sonat (now merged into Transocean Offshore) in the late 1980s and one as a production platform for Petrobras in the 1990s. In comparison, the GVA 7000 has a reduced air gap (12.5m), shorter columns, an increased water-plane area, greater deckload, and a generally improved layout.

The new design is rated for drilling in water depths of 10,000 ft, and for drilling to subsurface depths of up to 40,000 ft. Offline activities are made possible by the one-and-a-half derrick concept. The variable deckload capacity is 7,000 tonnes. The deck measures 90 m x 71 m, the operating draft is 20.5 m and operating displacement 35,900 tonnes.

The design offers dynamic positioning capability in either DP2 or DP3 class. According to the owner’s preference, it can have two or four engine rooms. There are six 5.5 MW diesel generators and six thrusters, with accommodation for up to 150 personnel.

For more information contact Robert Ludwigson, GVA Consultants. Tel +46 3110 6770, fax +46 3110 6710,[email protected], www.gvaconsultants.com.