Diverless solutions help bring production online

Taylor Puskar and Brad Brister, Oceaneering

Saturation diverstraditionally carry out inspection, maintenance and repair (IMR) work at subsea installations. However, it is not always possible to use divers due to operator safety concerns over divers working in high current offshore environments.

Those safety concerns led one operator to contact Oceaneering to retrofit existing subsea hardware at a field offshore Trinidad and Tobago, enabling subsea connectivity with remotely operated vehicles (ROVs).

The solution was to custom-engineer specialty ROV tools and equipment to solve the operator’s challenge. The equipment not only proved that ROVs could perform delicate tasks for retrofitting subsea hardware and integrating fit-for-purpose hardware with existing subsea architecture, but that future IMR work could be accomplished with engineered solutions versus diver intervention.

The operator opted for a retrofit of subsea hardware at the field due to the high cost of using diving services in the remote location, coupled with weather and water currents that made the field’s subsea infrastructure inaccessible to divers most of the time.

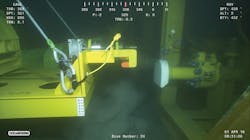

Oceaneering custom engineered the pull in frame (left in the picture) and the API by Grayloc Flange Adapter (at right) to convert a field offshore Trinidad and Tobago for diverless capacity. The pull in frame was installed to prepare for pulling in a flexible jumper to connect at the manifold. The adapter was installed by ROV to provide an interface for the subsea connection of the flexible jumper. (Images courtesy Oceaneering)

The field

The field had not produced for a three-year period after the previous operator unsuccessfully attempted to bring production online.

The existing subsea system consisted of a four-slot manifold connected to three horizontal trees via flexible well jumpers, electrical flying leads and steel flying leads. All the connections had originally been made with saturation diving support.

The challenge

Executing the project would require the re-route of existing flexible jumpers and the installation of new flexible jumpers to interface with the existing subsea production system. The project also involved horizontal flange connections, which were recessed in the manifold’s super structure, making them more difficult to access. Without the use of divers, no standard solution existed for addressing these flanges.

Removing the existing flanges and adopting American Petroleum Institute (API) flanges to enable remote connectivity would require ROVs to work in tight spaces. To create a solution, Oceaneering conducted an ROV access study for the field. The study indicated that, although the ROV had extremely tight tolerances and some limitations, tooling and installation aids could be developed to overcome the challenges and provide a diverless installation solution to complete a three-well tie-in, bringing the field into production.

Building bridges

The development of specialty ROV tools and installation equipment were needed for this project. ROV-operable flange removal tooling and an API by Grayloc flange adapter were created to adapt an API flange to a Grayloc hub to enable a remote clamp connection. To connect the two flexible jumpers while subsea, a flexible jumper bridge was built that provided adjustment in three dimensions. A flexible jumper pull-in frame and flexible jumper hang-off frame were also designed and built. The hang-off frame addressed the challenge of holding recovered flexible jumpers on the side of the vessel during flooding, flange removals, make-ups and pressure testing.

A Grayloc clamp (located in blue on the left) was used to make the subsea connection. The yellow subframe (located front-center in the picture) is the portion of the pull in frame that allowed alignment of the flexible jumper to the manifold.

The campaign

The project was conducted in two offshore campaigns in 1Q and 3Q 2018. During the first campaign, two API flanges were converted for ROV access, and a wet parked flexible jumper was installed. The manifold blind flange was removed using the ROV-operable tools and the flange adapter tool installed. Next, the pull-in frame was deployed and the flexible jumper recovered to the hang-off frame, where a Grayloc Remote clamp was installed on the end fitting. The flexible jumper was then landed into the pull-in frame, aligned and the remote connection was made.

The second campaign involved re-routing and performing the diverless conversion of an existing flexible jumper, making a remote connection on the flexible jumper bridge connection, and installing a new flexible jumper via a pull-in frame. To conduct this work, the existing flexible jumper connection was removed and shifted to the bridge. The API flange was adapted by installing the flange adapter and the new extension flexible jumper was shifted into the bridge with the remote clamp pre-installed. The bridge was then aligned and the remote connection made.

The pull-in frame was then deployed and installed onto the manifold. A new flexible jumper was deployed into the pull-in frame with a yoke assembly installed, aligned and the remote connection made. The final connections were tested via a multiple quick connect interface.

Conclusion

In addition to the high current conditions and difficulties installing ROV-friendly equipment onto assemblies built for diver use, there were several challenges on the project, including an extremely tight schedule for project planning, engineering, and fabrication and testing of hardware and installation aids.

The company also had to build equipment and tooling based on third-party construction drawings without access to perform a fit check prior to installation. To address this challenge, products were validated through controlled testing with ROVs at NASA’s Neutral Buoyancy Laboratory (NBL). Oceaneering’s first step for the NBL testing process was to provide a storyboard of the operations for the NBL ROV pilots, as well as ensure that the tooling and structures that would be used in the pool were compatible with the facility requirements. After the scope was established, a scope of supply drawing and the procedure were developed.

Testing took place over a four-day period, with the ROV performing all operations in a controlled environment to validate the custom-engineered ROV tooling. Minor lessons learned were incorporated into the tools to improve the ROVs ease of operability, such as adjusting handle lengths and angles, since the work took place in extremely tight tolerance areas.

Despite the challenges, the project allowed the operator to connect three new wells into the existing production infrastructure, and bring gas production online. Production is expected to peak at 250 Mcf/d. The project was completed within budget and on schedule, with no lost time incidents for the 44,628 man hours worked. The work on this project proved that the techniques and equipment deployed could be used for future diverless conversion projects. •