Brian Duthie

Florence Gauld

Fugro-Rovtech Ltd.

Natural gas from Reliance Industries’ Krishna-Godavari D6 block offshore India came onstream last year following a fasttrack to production that saved one-third of the usual time required.

The KG-DWN-98/l (KG-D6) lies in the Krishna-Godavari basin, Bay of Bengal, off India’s east coast. In nine months, gas production from 16 producing wells is 60 MMcm/d (2.33 bcf/d) and cumulative production is 9 bcm (317.8 bcf).

The project was completed in six-and-one half years, two-thirds of the time normally needed to develop a project of this magnitude with similar deepwater facilities. The seabed slopes sharply causing water depths to vary between 100 m (328 ft) and 1,700 m (5,577 ft). Additionally, the fair weather window is only four months/year.

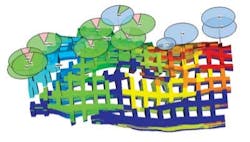

Wells are connected by flowlines and production risers to a control and riser platform and are tied back to the terminal about 60 km (37 mi) from the gas fields – one of the longest tiebacks in the world.

One reason for the fasttrack success was Fugro and its dedicated ROV service vesselSkandi Carla. The fasttrack development of this field involved one of the biggest, most complex underwater installation campaigns.

At the seabed, equipment equivalent to more than 110,000 tons (99,790 metric tons) of steel and more than 2,400 line km (1,491 mi) of flowlines and umbilicals were installed to construct the deepwater production system. Subsea installations were carried out by Fugro’s ROVs at seabed depths ranging from 600-1,200 m (1,968-3,967 ft). Subsea work included tying 19 subsea trees into six, six-slot production manifolds weighing 225 tons (204 metric tons) each. The longest tieback was 6.4 km (4 mi). From these manifolds, production flows through in-field pipelines to the 370-ton (336-metric ton) deepwater pipeline end manifold (DWPLEM). The longest manifold tieback is 6.8 km (4.4 mi).

Skandi Carla was involved with umbilical testing, infield support for the Lorelay and Audacia pipelay vessels, as well as the pre-lay survey work. The vessel also assisted with deepwater manifold activation (DMA) installation and tensioning, the installation of the DWPLEM structure, as well as other field support tasks requiring ROV capability.

The umbilical distribution hub weighs 170 tons (154 metric tons) and there are three 110-ton (100-metric ton) subsea distribution assemblies. The 32 lengths of steel-tube umbilicals total 101 km (63 mi) and there is 57 km (35 mi) of electric power cable. The installation also has a comprehensive subsea control system.