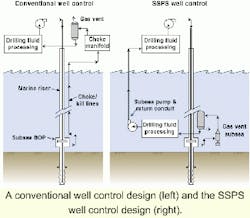

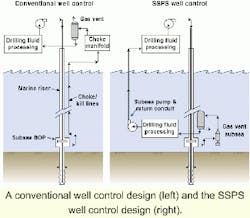

A conventional well control design (left) and the SSPS well control design (right).

Dual gradient drilling is the focus of several research initiatives. Ultimately, this may be a key technology to take exploration drilling out past 12,000-ft water depth. It promises to improve the margin between fracture gradient and pore pressures in deepwater wells, allowing casing strings to be set deeper and reducing the cost in time and materials to drill a well.

Rome Gonzalez, Senior Staff Drilling Engineer for Shell E&P said his company has become expert at operating near the technical limit of conventional drilling methods, and now they are working on extending that limit.

The subsea pumping system (SSPS) being funded and developed by Shell E&P works on a simple premise - creating ambient seawater pressure above the subsea BOP. Doing so significantly improves the pore pressure/fracture gradient margin in the well.

The goal was to design a system that accomplishes dual gradient drilling while using as much established technology as possible. This would mean greater reliability for the hardware and greater familiarity and safety for the operators. Gonzalez said to accomplish this goal, Shell faces two key hurdles.

- Primary subsea cuttings separation allows the company to use electrical submersible pumps (ESP).

- Subsea well control vents gas subsea, protecting rig personnel and eliminating the need for high-pressure containing equipment downstream of the subsea choke.

This alteration means the fluid returns conduit will not be high pressure. Shell E&P funded this effort on its own, beginning in 1996, and has worked with a number of vendors including FMC Kongsberg, Alcatel, Centrilift, Dril-Quip,, and Robicon.

The design of the SSPS is fairly complete, Gonzalez said. Most of the control and electrical systems design and procedures are also nearing completion. The plan is to build a prototype of some of the subsea equipment involved in the system and perform initial tests offshore on a surface facility. Gonzalez said this should happen sometime in May.

Circulatory system

Through these tests, Shell hopes to verify that the circulating system works right. Then the system will move subsea. "We have a high degree of confidence that our guys know how to make these types of subsea systems work," he said.

For the SSPS to work using ESPs, Gonzalez said the larger drill cuttings and other solids have to be removed upstream of the pump. ESPs use impellers to move fluids. Heavy or large cuttings would damage these impellers and possibly clog the return riser. In addition, this subsea processing reduces the functional requirements of the ESPs. The pumps are not required to handle large-sized materials or high-pressure gas during a well control event.

Gonzalez said rather than design new pumping technology, Shell has created a system that performs some basic subsea processing. This includes separating out the gumbo mud, larger cuttings, cement, float material, and other materials that could clog or damage the system.

To accomplish this, fluids are transported via a flowline, immediately above the subsea BOP, to a nitrogen filled tank. The tank is open at the bottom to passively maintain ambient pressure inside the tank, and in the well, allowing cuttings to discharge. Inside the tank will be a gumbo slide with bars spaced 1/2-in. apart and inclined 45°. The high pressure drilling fluid is routed to allow jetting of the slide, if a buildup should occur. The cuttings larger than 1/2-in. will fall into a cuttings inductor ditch for discharge subsea. The drilling fluid flows on into the holding tank package.

Inside the holding tank, which is also open at the bottom to maintain ambient pressure, is a cuttings slide with a 1/4-in. grate for further separation. This tank is equipped with level sensors to control the pumping speed. From this tank, the flow is directed to a common header for the pump suctions. The partially processed drilling fluid is then pumped up the return riser to the surface for further processing.

What this system attempts to achieve is to move the gumbo screen to the seafloor, Gonzalez said.

"Being able to remove solids and (perform) well control subsea gives us the advantage of not having to do anything extraordinary with the pumps," he said. Although the larger cuttings are being discharged at the seafloor, Gonzalez said he believes the amount of synthetic drilling fluid on these cuttings will be small, and should not be a problem from an environmental standpoint. "We will meet or exceed permit requirements." For the shallow drilling program, water-based muds will be used. The cuttings can also safely be discharged into the sea.

Subsea well control

Another element key to the dual gradient system is subsea well control. Gonzalez said the well control procedures designed into the system are very simple and safe. As with the circulating system, the well control system is designed to mimic conventional surface processes subsea.

The SSPS uses a subsea choke and vents gas at the seabed. As a result, high-pressure containing equipment is only required upstream of the choke. The pump and return conduit systems are not high pressure.

When a gas kick is detected, a preventor will close securing the well. As with a conventional system, the driller will receive sufficient information to allow early kick detection, calculation of the proper weight for the kill mud, and the proper drill pipe pressure/ volume schedule to adjust the choke and circulate out the kick.

The flow from the well is diverted from the subsea choke to a subsea mud/gas separator. The separator is a nitrogen filled vessel, similar to the one used for solids separation. The venting pressure is passively controlled to be equal to the ambient seawater pressure. This method ensures minimal pressure fluctuations from upstream of the choke back into the wellbore, avoiding the danger of secondary kicks and/or broaching of the formation. Once the drilling fluid is transferred to the holding tank package and pumped to the surface, the flow may be directed to another mud/gas separator for added safety.

Full drilling function

While there are specific zones of a well where a broader margin between the pore pressure and fracture gradient are key to a successful drilling program, Gonzalez said the SSPS is designed to be used throughout the drilling of a well from surface to total depth (TD). There is a broad range of advantages offered by dual gradient drilling, explained Gonzalez:

- Casing strings can be run deeper without the risk of exposing the formation to the high pressures of the mud column. This not only means fewer casing strings, but a larger wellbore at TD.

- Smaller deckloads for rigs and lower hook loads will result. This means smaller rigs might be called into service to drill deepwater wells.

Shell has left the door open to a variety of configurations for the SSPS. Gonzalez said these configurations could adapt the system to use on dynamically positioned or moored vessels and on semisubmersibles or ship-shaped mobile drilling units. There is even a version of the system that would operate riserless with the casing and drill pipe run through open water and only a return conduit communicating with the surface.

Testing will begin shortly, but there are no firm plans for the first application of the SSPS.