Mooring component specialist MoorLink has introduced a new design of subsea connector for mooring offshore floaters that has already been bid for numerous projects, according to managing director Björn Palmquist.

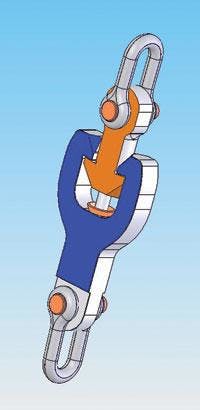

The connector provides the link between the suction anchor, pile, or drag anchor and the mooring line. Ahead of installation, one part is attached to the anchor and the other to the end of the mooring line. An ROV is used to attach the mooring line to the anchor by joining the two parts of the connector together. Ease of connection is a key design requirement, as is stability, once the connection is made.

MoorLink has been careful to ensure that its subsea connector design cannot be confused with existing designs. It recently received confirmation from the Swedish patent office that the design is considered distinct from other designs and therefore patentable. The company has also filed patent application in the US.

Finite element analysis of the design has been carried out to demonstrate its structural integrity and ability to maintain fatigue life. The next step will be the manufacture and testing of a prototype, Palmquist says. This will be a connector with 600-700 metric tonnes breaking load intended for use with the 3-in. chain employed typically by mobile drilling rigs. The whole unit will be about 1.5 m in length and weigh around 450 kg in air.

One of the prime benefits of the MoorLink connector, he adds, is that it is constructed from high quality steel plate, which means it can be built under license in countries where importing the product could run into customs problems, or where there might be local content requirements.

MoorLink�s subsea connector.

Another advantage is that if the customer decides to change specifications, for example to a higher breaking load, such changes can be taken on board at a late stage in the project.

The company is responding to a requirement for more competition in the market, where there are only a handful of suppliers, Palmquist says. Some of the existing connectors are also expensive, and the company sees a good opportunity to offer a cost-effective solution.

Another driver for continuous development of the subsea connector comes from the regulatory authorities, especially in areas such as the Gulf of Mexico, where the damage inflicted on offshore installations by hurricanes such as Katrina only last August focuses attention on the need for more efficient moorings.•