Thomas Schüller, Butting

Inthe early1990s, Butting developed the mechanically lined Butting-Bimetal-pipe (BuBi pipe), a longitudinally welded pipe made from stainless steel or a nickel-based alloy which is telescopically aligned inside a carbon-manganese steel pipe and mechanically connected by means of a hydro-forming process. This product combines the strength and toughness properties of carbon-manganese steels with the high corrosion resistance of stainless steels or nickel-based alloys.

BuBi pipes have since been used widely for demanding applications in oil and gas production, mainly offshore pipelines, risers, and steel catenary risers. They can be installed via S-Lay, J-Lay or in bundles, although the reel-lay method is, in general, the most cost-effective. Cost considerations were also the basis for the company’s most recent innovation, the GluBi pipe: this is a glue-bonded, mechanically lined product that can be installed by the reel-lay process without using inner pressure or increasing the wall thickness of the corrosion-resistant alloy (CRA) liner.

The installation process is playing an increasingly major role in the selection of clad pipes. While reeling remains the most cost-effective technique for pipelines and risers, bending of mechanically lined pipes is restricted when reeling. Depending on a variety of factors such as wall thickness, outside diameter and bending radius, wrinkles may be formed in the liner of a traditional mechanically lined BuBi pipe - hence the new development, which is designed to reduce the cost both of materials and of pipelay while providing improved product performance.

BuBi pipes in Knesebeck. (Images courtesy BUTTING Group GMBH & Co)

Although the idea for a glued pipe first arose in 2000, development initially proved impractical as the pipe could not be welded. However, work on the concept re-started in 2009, and eight years later, Butting was able to present a glued pipe with weldable pipe ends to oil companies and EPC pipelay contractors. The principle is innovative: the basis is a mechanically lined BuBi pipe, with an additional special adhesive between the carbon-manganese steel and the corrosion-resistant liner. But selecting the optimum adhesive proved to be a major challenge.

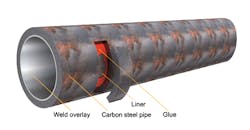

There are a number of variants available for the GluBi pipe – both for the carbon-manganese steel and for the corrosion-resistant liner – and for possible combinations. The production process, which entails very tight tolerances, corresponds to 90% of the method applied for production of BuBi pipe. The main difference is that with the GluBi pipe the outside surface of the liner is connected to the inner surface of the carbon-manganese pipe by an adhesive, and the pipe ends are specially prepared for weld overlay welding. The pipe ends are cladded using the gas metal arc welding (GMAW) process with two layers, with the same welding procedure specifications applied as for BuBi pipes. As a result, the ends of the GluBi pipes correspond to the ends of the BuBi pipes, and the behavior of the GluBi pipe ends during circumferential welding is also identical to the behavior of the BuBi pipe ends.

In 2010, Butting developed a test rig to simulate the reeling process which it installed at its main production complex in Knesebeck, Germany. The test rig enables simulation of many different applications and uses of the pipes. Over the past few years the company has conducted various repeat tests with GluBi pipes.

The first two stages of the qualification process of the GluBi pipe in accordance with DNV-RP-A203 (together with DNV GL) were completed in 2017, and the third stage of qualification will conclude by the end of this year. Various tests remain to be performed including simulations using a finite element model provided by DNV GL to ascertain all factors that may have an impact on the pipe. At a later point, the finite element model will be used to determine critical factors of different dimensions and material grades, which will allow critical temperatures in service to be defined. Butting also plans to develop non-destructive testing methods as part of its quality assurance procedure in order to be able to certify the existence of adhesive and its performance. To date, companies in the oil and gas industry and EPC contractors have reacted positively to the new product, and some have asked for test pipes to conduct further investigations.

To optimize manufacture of this product two new production halls are under construction at the main plant in Knesebeck, and all the machines and equipment will be installed during the current quarter. By the end of this year the continuous production process for the GluBi pipes should be in place, providing sizes in a range from 6-in. to 18-in.

A section of a GluBi pipe.

North Sea, Brazil applications

Butting has responded to the recent upturn in field development, winning orders for a series of major offshore projects. One involved producing nearly 8,000 metric tons (8,818 tons) of BuBi pipes in various dimensions for Equinor’s Snorre expansion project in the Norwegian North Sea. For the same client, the company is producing more than 5,000 metric tons (5,511 tons) of BuBi pipes 10-in. and 12-in. versions in the material combination DNV SMLS 450 SP / UNS 31603 mod for the Peregrino Phase 2 project in the Campos basin offshore Brazil.

Other orders in the northern Europe area include 37 km (23 mi) of 12-in. BuBi pipes in the material combination DNV SMLS 450 SFPDU / UNS 31603 mod. for Neptune Energy’s Fenja-Njord subsea tieback in the Norwegian Sea; and 9.5 km (5.9 mi) of metallurgically clad pipes with an OD of 273.1 mm (10.75 in.) for BP’s Alligin project in the UK sector.

The company has also been producing around 3,000 metric tons (3,307 tons) of metallurgically clad pipes and elbows in various sizes for the ramp-up to plateau phase of the deepwater Zohr project in the Egyptian sector of the Mediterranean Sea; and more than 1,600 metric tons (1,763 tons) of metallurgically clad 12-in. and 16-in. pipes in the material combination X65 MOS / UNS N06625 for Saudi Aramco’s Hasbah and Arbi field project offshore Saudi Arabia. •