Gene Kliewer - Technology Editor, Subsea & Seismic

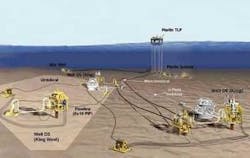

BP’s King field in the Gulf of Mexico in Mississippi Canyon blocks 84, 85, 128, and 129 is the first subsea multiphase pump application in more than 1,676 m (5,500 ft) of water and more than 24 km (15 mi) away from its host TLP – double the records for each measure. The previous records were 914 m (3,000 ft) of water and 9.7 km (6 mi) from the host. Then Aker Kværner Subsea pumps also set a pressure differential record of 50 bar (5 MPa) over the pump.

“The two (multiphase) pumps will enhance production from the King field by an average of 20%. In addition to the increase in production, the project will allow a 7% increase in recovery, extending the economic life of the field by five years,” says BP.

“In line with our strategy to maximize reserves from out existing fields, the application of this cutting edge technology across BP’s large deepwater portfolio has the potential to unlock significant resources that would otherwise remain unrecoverable,” says Andy Inglis, BP’s chief executive of E&P.

King is tied back to theMarlin TLP, which is approximately 75 mi (121 km) offshore Louisiana in Viosca Knoll block 915.

New technologies and techniques developed for this project include:

- A long distance high voltage distribution system capable of controlling multiple pumps at different speeds using advanced variable-speed drive systems. This overcame two challenges: umbilical designs that avoided “cross talk” or interference, and the use of simplified 12 kV ROV (remote operated vehicle) connectors to increase reliability

- Umbilicals linking the pumps to the distant control platform were developed as self-contained delivery lines for hydraulic fluids, chemical feeds, and lubrication oil, to reduce weight and cost

- The umbilicals also house a new fiber optic communications system to ensure high speed pump response in respect to speed and lubricant oil pressure

- Each pump station is mounted on a suction pile with the pump installed inside a manifold, and measures 33 x 20 x 13 ft (10 x 6 x 4 m) and weighs some 92 metric tons (101 tons). The umbilical and connectors are rated to supply 6,600 V to the subsea pump.

Aker Kvaerner of Norway supplied the subsea pumps, as well as installation services. Nexans of Norway supplied the umbilical. Installation services were supplied by Saipem and AMC.

In addition to the three MultiBooster subsea pumps, King also has variable-speed drives, high-voltage subsea connectors and jumpers, topside and subsea control systems, a topside lube oil hydraulic power unit, manifolds, and tie-in system. A condition monitoring system is built into the controls and gathers data from sensors on each pump about vibration, pressure, and temperature.

The pump internals are 1 MW Bornemann MPC-335 twin-screw units with screw diameter of 335 mm (13 in.). An advantage of the twin-screw pump, according to Aker, is that it can handle a range of gas void fractions, from 0% to 98%, which is necessary in fields with high gas proportion. The pump also is self-priming and runs at rates up to 1,800 rpm, which should extend pump life.

For installation, the pumps were located in stations consisting of a skid in a manifold. Each station was installed in a single lift.

MARS system

Two of Cameron’s CAMFORCE Subsea Processing technologies – MARS (Multiple Application Reinjection System) and POSSibilities (Production Optimization Simulation Software) – are part of the King project.

MARS serves as the interface between the subsea production tree and the processing equipment modules (pumping, metering, separation, or well stimulation). The technology has been developed and supplied by DES, a wholly owned subsidiary of Cameron.

The patented MARS system enables processing equipment modules to be installed on the subsea trees at any time and provides a universal interface.

POSSibilities software is used to compare numerous production optimization solutions and configurations throughout the life of the field.

The BP King project is the first field application of both the MARS and POSSibilities technologies.

Umbilical innovation

In addition to containing both high- and low-voltage electrical power, the umbilical provides fiber optic communications, chemical injection, and lube oil services.

Nexan says the concept of integrating HV power cables in a subsea umbilical was both a mechanical and electrical design challenge, particularly the electrical interference between conductors and inductive losses in the steel tubes.

Nexans’ integration of both power cable and other umbilical functions into a single unit allows a 24,000-V supply to be provided to the deepwater project, which had not previously been done. This also allows more efficient transportation and installation umbilical functions rather than having to resort to separate umbilical and power cables.

Cast-in-place syntactic foam on lines, PLEM

The King field’s six-mi (10-km) long pipeline and PLEM (pipeline manifold) sleds are coated with cast-in-place syntactic foam insulation expected to last 20 years. The flowline is part of the Shell-operated King subsea project in Mississippi Canyon block 807 in the GoM.

The flowline is in 3,300 ft (1,006 m) water depths at an internal temperature of 170º C (338º F). Cuming Corp. coated the lines with a patented casting process which had not been used before. Cuming says that syntactic foam offers higher thermal efficiency and better resistance to hydrostatic pressure.

The insulation was applied to the pipe at Cuming’s factory in New Iberia, Louisiana. The pipe joints were assembled nearby and barged offshore for J-lay installation by McDermott’sDB 50.

Sealing technology

Mechanical seals from Huhnseal protect record-depth multiphase pumps. This application broke new ground, also, as the installation depth for the equipment. The differential pressure over the seal faces, which are made of silicon carbide, will be 20 bar (2 MPa). Huhnseal’s customer is the pump manufacturer Bornemann. The seals are installed where the shaft passes through the pump casing, separating the clean oil lubricating the electric motor and transmission from the multiphase flow of oil, gas, water, and sand.

A planning system to coordinate the hundreds of tasks involved with installation, hookup, and commissioning/startup was designed by EDG Inc. According to the developers, the system increases hookup crew efficiency, accelerates first oil, reduces shut-in time, enhances safety performance, and reduces overall project costs.

The system divides all offshore tasks into major task groups: structural, mechanical, instrumentation and electrical, commissioning, and start-up.

null