Gene Kliewer , Houston

Subsea equipment ordered for North Sea

Grenland signs with FMC: FMC Technologies has send a letter of intent to Grenland Group to fabricate, assemble, and test subsea structures for Norsk Hydro’s Ormen Lange Southern field. The largest unit is an eight-slot manifold with a protection structure of approximately 1,100 metric tons (1,213 tons). The production systems are scheduled for fabrication at Grenland’s yards in Grenland and in Tonsberg, Norway.

Ormen Lange Southern field is an expansion of the Ormen Lange field. It is 120 km (75 mi) off the western coast of Norway at a water depth of 900 m (2,950 ft). Delivery of the subsea structures is scheduled for Nov. 2008.

Aker Kværner to supply Subsea 7 umbilicals:Also in the North Sea area, Aker Kværner has contracted to supply Subsea 7 Norway with steel tube umbilicals for Norsk Hydro’s Vega and Troll O2 development. At NOK 434 ($74.5 million), this is one of its largest stand-alone umbilical contracts to date, Aker says.

Aker Kværner Subsea will delivery 60 km (37 mi) of static and dynamic umbilicals to Subsea 7. Work will begin immediately at Aker Kvaerner Subsea’s facility in Moss, Norway. Delivery is scheduled for April 2009.

Statoil picks risers: Statoil has sent a letter of intent to NKT Flexibles for engineering, procurement, and construction of flexible risers for Gjøa and Visund in the North Sea. Value of the contracts will be NOK 500 million ($86.9 million) for seven flexible risers at Gjøa and NOK 135 million ($23.4 million) for three flexible risers at Visund. Delivery is scheduled for 2Q 2009.

The risers for Gjøa are between 690 m and 730 m (2,264-2,395 ft) long and have an internal diameter of between 14 in. and 16 in. (35.5-40.6 cm). The risers for Visund are between 970 m and 1,120 m (3,182-3,675 ft) long with an internal diameter of 6 in. (15.25 cm).

Delmar installs 100th subsea tree

Delmar Systems Inc. says it has installed its 100th subsea tree using the patented heave compensated landing system. The method reduces heave motions at the mudline caused by sea conditions on surface, says Matt Smith, Delmar’s vice president of operations.

“The system provides ‘automatic’ motion compensation, eliminating any tuning or adjustments due to changes in weather conditions. Heave motion is negligible, whether the equipment is being installed in lightly choppy seas or long period swells, thus allowing for a soft landing on the wellhead or seabed in a very controlled and accurate manner,” Smith says.

SeeTrack automates ROV controls

SeeByte Ltd. has launched SeeTrack Offshore, a dynamic positioning system for ROVs that aims to automate the ROV control process to compensate for currents. The system can be retrofitted to existing vessels, the company says.

The system “can tangibly improve offshore operations. SeeTrack Offshore makes operations safer and quicker,” says Ioseba Tena, SeeByte product manager. “The technology fuses information from various sensors and takes the control inputs from the ROV joystick to compensate for current and tether effects so that when the pilot pushes forward the ROV actually moves forward.

Field testing establishes ROV control system automation. Image courtesy of BP.

“Our experience in trials carried out west of Shetland and in the Gulf of Mexico has shown that the hover performance of an ROV operating with SeeTrack Offshore is better than the performance of an ROV operating without it.”

Installing SeeTrack Offshore requires no modifications to the ROV, the company says. The system runs on the surface and is contained in a 19-in. (48-cm) rack. SeeByte says it can install and tune the system with no impact on normal operations.

Norway studies offshore power option

Norway’s Ministry of Petroleum and Energy has asked the Norwegian Petroleum Directorate to lead the Norwegian Water Resources and Energy Directorate and the Norwegian Pollution Control Authority in an analysis of issues regarding providing land-based power to petroleum facilities offshore.

Scheduled for completion by the end of this year, the study updates work done in 2002. The program will investigate questions about connecting new and existing facilities on the Norwegian continental shelf to power supplies from land. Technical evaluations, the effect on Norway’s electric power balance, and HSE factors are to be included.

BP, Expro to develop subsea wireline intervention system

Expro International Group Plc. has agreed with BP to develop the AX-S lightweight subsea wireline intervention system. Upon final contract, Expro will build a system, and BP will conduct field trials. The AX-S system is aimed at the growing market for lightweight well intervention services to diagnose production problems and to improve production from subsea wells.

“This announcement is the result of a focused engineering exercise over the last two to three years,” says Graeme Coutts, Expro CEO. “AX-S will offer a ‘step change’ in well flow management of subsea wells. We are delighted that BP, who have jointly worked with us from initial project conception, continue to recognize the potential for AX-S in their long-term vision of deepwater field management.”

null

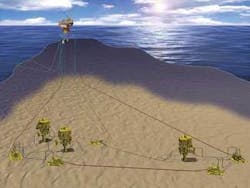

Entrada hits the fasttrack

Callon Petroleum Co. has contracted JP Kenny Inc. to engineer, procure, and manage the installation and overall project for the Entrada field in 4,600 ft (1,402 m) of water in the Gulf of Mexico’s Garden Banks blocks 782 and 783. JP Kenny is fasttracking the project to meet Callon’s 1Q 2009 startup target. The field initially will be produced as a two-well tieback to the Magnolia platform. It will have a flowline pigging loop with inline sleds and pipeline end manifolds.