Chip Letton

The Letton-Hall Group

James Pappas

RPSEA

Bob Webb

BP

The US Department of Energy, through its Research Partnership to Secure Energy for America (RPSEA) initiative, working in concert with a consortium of seven deepwater operators, sponsored a joint industry project (JIP) to address perceived gaps in measurement of flow in deepwater. The project consists of six individual sub-projects, each addressing one of the identified gaps: deepwater subsea sampling, ROV-conveyed measurement, HP/HT sensor development, virtual flow meter evaluation, meter fouling effects, and measurement uncertainty tool development. This summarizes the efforts of each of these sub-projects (tasks) and addresses salient features of the project such as technology transfer and financial performance.

Since 1999, when Gulf of Mexico (GoM) deepwater projects passed the 1-mi (5,280 ft or 1,609 m) water-depth mark, work in deepwater has become exponentially more challenging.

The implications on measurement techniques and technology of working in ultra-deepwater are considerable, and have been recognized for many years. Starting in the 2000-2005 timeframe, operators in the GoM began to realize that measurement technology was ill equipped to deal with these future deepwater requirements, and began to discuss what could be done. A group of measurement specialists representing several of the major operators, service companies, and equipment vendors decided to address the issues collectively.

In late 2005, following a DeepStar measurement workshop, DeepStar Project 8302, Improved Multi-phase Metering for Subsea Tiebacks, was launched. Though noteworthy, this set the stage for a more ambitious attack to follow. During its final year, the DeepStar 8302 Steering Committee submitted a CTR to the Research Partnership to Secure Energy for America (RPSEA), part of the US Department of Energy's (DOE) effort to create a public-private partnership. RPSEA is chartered to manage project selection and to fund innovative E&P technology. Recognizing that improved deepwater measurement is critical, RPSEA in 2008 awarded the Letton-Hall Group (LHG) a contract for Project 07121-1301, Improvements to Deepwater Subsea Measurement, to address gaps in deployment and use of multi-phase and wet gas meter technology in deepwater production systems. Six technical sub-projects were identified as pivotal to close the technology gaps. These tasks are:

- 1. Deepwater subsea sampling. Development of methods for standardized deepwater well fluid sampling

- 2. ROV-assisted subsea measurement. Development of techniques for conveyance by ROV of clamp-on measurement to the sea floor

- 3. HP/HT sensor qualification. Development and qualification of DP sensors for high pressure/high temperature applications

- 4. Evaluation of flow modeling. Evaluation of the effectiveness of wellbore flow models, such as virtual flow meters

- 5. Meter fouling effects. Understanding of how fouling of meters affects their response

- 6. Metering system uncertainty. Development of tools to model uncertainties in a subsea-topside measurement system.

Work began in October 2008.

Measurement R&D

Although there are many reasons for subsea metering, the most universal is simply that deepwater production is driven by economics. The cost of equipment determines how the fluids will be produced and conveyed to the surface, and measurement practices must adapt to this reality. Given that the cost of deepwater, high-pressure oil or gas flowlines are typically $10 – 20 million per mile, a primary business driver is clear -- minimize the need for subsea pipelines. By commingling production as soon as feasible and eliminating separate lines for testing wells, tens of millions of dollars are saved.

The implications of commingling and test line elimination on well flow measurement are significant. Tests on individual wells through production flowlines are impractical, primarily due to the cost of deferring production from wells not on test. Schemes such as "well-test-by-difference" generally yield poor results and should be avoided. Thus, some form of local subsea measurement is the only practical way to obtain individual well rates.

One question is how reliably the measurement of multi-phase flow from each well can be made over the life of the field. Can a meter installed on a well at the field startup give reliable, accurate oil, gas, and water flow rates measurements five, 10, or 20 years later? Could something change? Might produced fluids properties change? Perhaps the well has produced substances that now coat the inner walls of the meter, and if so would the meter's normal response be altered?

The important point is that conditions likely will change with the passage of time. Considering the potential costs of poor measurement, improving our understanding what is required for proper flow rate measurement in deepwater is clearly crucial.

Organization and finance

The CTR for 07121-1301 was submitted as the seminal work of DeepStar Project 8302 was entering its final stages. The DeepStar effort was populated by many of the same operator-experts who later signed on with RPSEA, and helped to define the gaps that 07121-1301 has sought to address. By the time work began on RPSEA Project 07121-1301 in 2008, LHG had organized a joint industry project (JIP) to co-fund 20% of the project cost as is required by RPSEA. Founding JIP members were BHP Billiton, BP, Chevron, ConocoPhillips, Shell, StatoilHydro, and Total.

In addition to funding they provided expertise in both deepwater engineering and measurement during the definition and execution stages for each Task. This was critical. Knowledge of deepwater measurement and related subsea operations is scarce.

As well as an experienced and knowledgeable project JIP, LHG required special outside expertise in several special areas of subsea measurement and operations. Key subcontractors employed by the Task Working Groups included Oceaneering International, Multi-phase Systems Integration, Neftemer Ltd., TUV NEL, Southwest Research (SwRI), and axept.

Task 1 – Deepwater subsea sampling

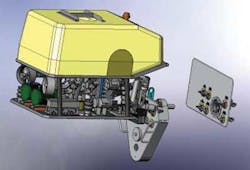

The objectives were to review existing sample systems and conceptual designs of sampling systems deployed via ROV for potential as standardized sampling systems, to select a candidate for development and testing in a high-pressure multi-phase flow loop and with an ROV in a simulated subsea operation, and to develop and publish draft standards for sampling connections (interfaces), tools, and other equipment.

All Task objectives were met. After narrowing from 11 possible systems to one, and once the prototype equipment was designed and fabricated, the unit was tested in the high-pressure multi-phase flow loop at SwRI in San Antonio, and later at the Oceaneering (OII) subsea simulation facility in Morgan City, Louisiana. SwRI tested the fluid dynamics of the sampling process, with samples captured at six different points in a typical subsea piping arrangement and later compared to reference samples acquired by commercial sampling vendors. The OII Morgan City test evaluated the operability of the sampling system when manipulated by a commercial ROV in a marine environment.

The specifics of the sampling system interface with the ROV are available as ade facto standard to encourage other sample system and ROV vendors to enter this technology arena.

Task 2 – ROV-assisted subsea measurement

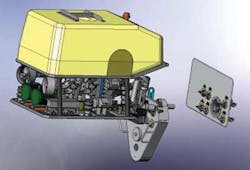

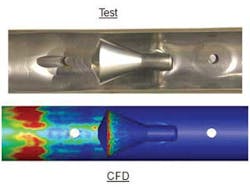

Task 2 aimed to deliver supplemental measurement to a multi-phase metering site in the subsea pipework to verify operation of metering equipment in place. Specifically, the task was to understand what can be expected in the deepwater from available sensor systems, to identify present or future constraints on ROV operability, and to develop "landing-zone" and sensor system specifications for ROV-conveyed measurement. The Task was also important in that the hardware used by the ROV to apply the meter to the flowline in a predictable and repeatable way would become thede facto standard for such work.

These goals were met. After the Task Working Group approved the concept and the prototype system was designed, tests were done at the Oceaneering in Houston (source-receiver alignment sensitivity), at the SwRI high-pressure multi-phase flow loop in San Antonio (measurement performance under various flow regimes, comparison of differences between metering in water versus air), and at the Oceaneering subsea simulation facility in Morgan City (operability of the metering system when being manipulated by a commercial ROV in a subsea environment).

Specifics of the interface between the ROV-conveyed meter and the flowline (i.e. the landing zone) are published to encourage other ROV and metering system vendors to enter this technology arena.

Task 3 – HP/HT sensor qualification

The initial Task 3 objective was to address the operational restrictions that prevented use of the most sensors in multi-phase and wet-gas flow meters, i.e., those that measure pressure (P), temperature (T), and differential pressure (DP). A program was to be formulated to increase the P-T-DP operational envelope of these key sensors – currently limited to 10,000 psig and 125 °C (257 °F) – by a new design aimed specifically at this issue. The new sensing elements would be integrated into transmitter housings designed to meet operational pressures of at least 15,000 psig at an ambient temperature of 250 °C (482 °F). The integrated transmitters would then be tested according to a qualification program developed as part of this Task.

A design and fabrication organization specializing in micromachined (MEMS) silicon would be contracted to provide the HP/HT pressure and differential pressure sensing elements, which would then be incorporated into pressure cells to be integrated into high-pressure meter housings.

A change in specification was made based on the Working Group's recommendation. Since HP/HT pressure sensors exist, the decision was made not to attempt to develop a measurement-grade P sensor, but only one that could be used to make common-mode corrections to the DP sensor readings.

The goals of the project have been achieved. Two iterations of both the MEMS chip and the pressure cell were required in order to meet the Task goals.

Task 4 – Evaluation of virtual flow meters

This Task was to address the gap in documented studies of virtual flow meter (VFM) technology by evaluating the performance of current commercial VFMs. The plan was to compare the predictions of VFMs using as standards both real-world data, as well as that from flow simulators. The intent was to document the performance of VFMs as a group, and as generic sub-groups within the larger family, identifying areas of strength and weakness. If successful, the effort would encourage the utilization of VFM technology in monitoring or allocation applications, in those cases where it fit.

Unfortunately, acquiring actual field data was so difficult that only simulated data was available for use, constructed from the most commonly used flow simulator, OLGA.

To enlist cooperation of commercial VFM vendors, it was agreed that the results of the investigations would be presented anonymously to avoid identification of specific vendors. Initially eight vendors agreed to participate.

The results were less significant than hoped. The absence of field data made vendors less enthusiastic than desired – an understandable reaction. However, this lack of testing on real data is viewed as temporary. The VFM evaluation is scheduled to continue in the new RPSEA Project 4304, with a different approach to guarantee realistic evaluations of pressure and temperature data from real producing wells.

Task 5 – Meter fouling effects

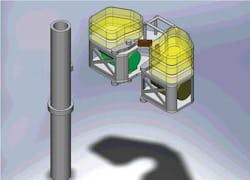

This work addressed gaps in understanding of how production alteration of meters affects their response. It is known from field operations that meters can become fouled or altered by deposits of scale, wax, asphaltenes, and hydrates, as well as from the processes of corrosion and erosion. The effects of these on measurement are not well understood, thus the primary objective was to understand the nature and magnitude of two of the more important of these, i.e. erosion and scale.

The original plan was experiments to evaluate the effects of alteration on some commonly used multi-phase meter elements such as venturi, cone, and wedge. Alteration mechanisms would be either deposition (scale or wax) or erosion. The Task Working Group (WG) agreed that scale was the major deposition problem in deepwater, and that erosion was the next most important issue. Therefore, these were the two phenomena chosen for investigation. Through the generosity of ConocoPhillips, an experimental data set for sand erosion in a venturi meter was made available. Additionally, the WG made a key decision early on to use computational fluid dynamics (CFD) "experiments" to augment laboratory measurements.

The resultant research included both lab and CFD experiments on venturi, cone, and wedge meters, for both scale build-up and erosion effects, the latter in both liquid and gas mixtures. The use of CFD in concert with the lab measurements allowed the extension of the results to an enormous number of possible cases (meter diameters, beta ratios, etc.) that would not have been practical using only laboratory experiments. The results surpassed expectations.

Task 6 – Metering system uncertainty

The intent of this task was to develop methods to enable users to calculate the uncertainty in flow measurement at the subsea meter, at the topside separator, and points in between. Merging models of multi-phase flow with separator and meter models into a unified system has provided a useful tool for the production engineer.

Uncertainty performance of the various components of the system – downhole and subsea pressure and temperature sensors, subsea or topside multi-phase meters, a length of tieback pipeline, a topside separator with single-phase flow and watercut meters – is input into the system through spreadsheets, as is the system geometry.

The tool uses separate models for gas-dominant and liquid-dominant systems. Base cases were built to cover typical subsea measurement system configurations. The tool provides a Forward Model, used primarily for uncertainty estimation. In the future, a Reverse Model may be developed in an attempt to identify a source of material imbalance in the system, if that imbalance is outside its expected bounds.

Conclusions

The results in the Final Reports for the six technical tasks that comprise 07121-1301 demonstrate that this pioneering RPSEA project has been a success. Among the accomplishments were:

- Achieving the cooperation of seven major deepwater operators in addressing a problem recognized by all as crucial, i.e. deepwater subsea flow measurement

- Making industry aware of the need for sampling strategies and identified mechanisms to sample production streams in deepwater.

- Developing a way to sample subsea, and to demonstrated the capability in both a high-pressure multi-phase flow loop and with an ROV in a subsea simulation facility

- Developing the first ROV-conveyed, clamp-on flow measurement equipment, tested it in the high-pressure multi-phase flow loop and with an ROV in a subsea simulation facility

- Developing the industry's first HP/HT differential sensor for use in deepwater

- Developing a way to evaluate virtual flow meters. This will be of use in the VFM evaluation part of the new RPSEA Project DW4304, if selected.

- Creating the first catalog of fouling effects (erosion, scale) on flow measurement through differential meters (venturi, cone, wedge). This is the most extensive and complete effort ever attempted on this topic.

- Developing a software simulation tool to model flow rate uncertainty in a multi-phase pipeline network, and to calculate the uncertainties of various important quantities (e.g., system balance).

Both the Department of Energy and the seven major JIP member-operators received value for the money spent on this work.

While the gains have been noteworthy, there is still work to be done to maximize the results from the effort, particularly in their application to safety issues in drilling and completion operations. This will be a major thrust of the new RPSEA DW4304 Project, if it is selected.

References

[1] HALL, J., WEBB, R., and W. LETTON. Deepwater Measurement Verification – a DeepStar-RPSEA Mandate, 26th North Sea Flow Measurement Workshop, St. Andrews, Scotland, October 2008.

[4] BARTON, N., ZANKER, K., AND G. STOBIE. Erosion Effects On Venturi And Cone Meters, The Americas Workshop, Houston, Texas, April 2010.

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com