Jeremy Beckman

Editor, Europe

Petrofac and Petronas have ordered a novel unmanned minimal facilities platform for their West Desaru development off Peninsular Malaysia. The free-standing Wellhead Support Structure (WSS) is an adaptation of Aquaterra Energy's Sea Swift platform, two of which are currently in service in shallow water offshore Angola. The WSS, however, will be the first installation of its kind in the Asia/Pacific region.

Aquaterra, based in Norwich and Aberdeen, UK, provides services ranging from well construction, including conductor/riser design and analysis, through platform engineering/retrofits, hookup and commissioning. The management team includes former senior figures at UK riser engineering specialist UWG, Norway's AGR Well Services, while managing director Patrick Phelan previously held a similar position at JDR Cables. Outside the UK, the company has a design/branch office in Kuala Lumpur.

"A lot of our work starts with riser and conductor analysis," Phelan said. "We tend to work right at the front end of projects with oil companies and their contractors, providing follow-up services as the project goes on. But minimal facilities engineering is our core expertise."

To date, Aquaterra has supplied Sea Swift platforms to Sonangol for installation on the Airoga and Solha fields off Angola, both in 25 m (82 ft) water depth. "These are conductor-supported minimal facility structures," Phelan explained, "providing a highly cost-effective way of establishing a new standalone oil field development or offshore step-outs from existing fields. The concept is designed for installation by the jackup drilling the wells, cutting out the need for a heavy-lift vessel. This reduces the overall developments costs and delivery time-frame. In the case of satellite projects, such as West Desaru, the wells can be established prior to arrival of the main production platform."

At West Desaru, the water depth is 65 m (213 ft), and the environmental conditions are relatively benign, similar to near-shore Angola, with extreme storm wave heights of just over 8 m (26 ft). The maximum water depth for the Sea Swift concept is around 80 m (262 ft). "Beyond that," Phelan said, "support of the topsides by the conductors alone may not be feasible." Other shallow-water areas with suitable metocean conditions are the Mediterranean Sea, the Middle East, Nigeria, and much of Southeast Asia.

Malaysian fabricator TH Heavy (Ramunia Holdings) is building the topsides and subsea structures, which will be bridge-linked to theFP5 mobile offshore production unit – Petrofac acquired the latter, formerly the Ocean Legend, from Oceaneering in 2011. Produced oil from the WSS will be processed at the MOPU before returning back to the WSS for export via a 14-km (8.7-mi) subsea pipeline to a floating storage and offloading (FSO) vessel.

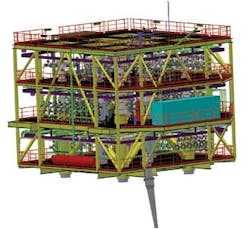

The WSS topsides will accommodate a total of 28 dry tree well completions (comprising single, dual and triple splitter wellheads) and associated oil production, gas lift and water injection flowlines. Additionally, the structure houses a wellhead control panel, control and safety systems, manifolds, pig launcher, and an 8-in. (20-cm) flexible riser.

There is no jacket - the topsides will be supported entirely by the four outer environmental well conductors, descending vertically to the seafloor and braced together "like a set of guitar strings," according to Phelan. The diameter and wall thickness of the leg conductors – respectively 36-in. by 2-in. (91 x 5 cm) – are both larger than for the Angolan Sea Swifts, due to the greater water depth. Each of the West Desaru conductors weighs just over 1 metric ton/m (1.1 tons/m).

The conductors will be connected via two 20-m (65.6-ft) tall latticed subsea structures and fixed to the seabed via the drilled and cemented four outer conductors to a depth of 80 m below the mudline. The subsea structures provide the strength and stability to hold the WSS in place, but they also create significant drag. This necessitated complex structural analysis to ensure that the WSS' 10-year minimum design fatigue life would be achieved.

Design parameters

"Every platform substructure we produce is a one-off design," Phelan explained. "The parameters vary according to the water depth, soil structure, and sea conditions. It's not just a matter of how rough the conditions are – you must take into account wave frequency, which at West Desaru is particularly onerous in terms of fatigue life and resonance on the entire structure."

Phelan continued: "If, during the front-end engineering design (FEED) phase, the client insisted on moving the platform's location by a few kilometers, where soil conditions may be different, this could lessen the structure's fatigue life from 15 to three years, which is unacceptable. In that case we would have to adapt the structure so the design conditions are not operating at resonance frequency of the system."

For West Desaru, the target was to have the platform installed and commissioned within 12 months of contract award. "Normally," Phelan said, "we would go from conceptual engineering to FEED, followed by detailed design and construction. In this case, however, the client went straight from conceptual design to issuing an engineering, procurement and construction (EPC) contract, in order to achieve time savings.

"Effectively, we had to combine two phases in one, ordering long-lead items while at the same time finalizing engineering. That involved critical path analysis and planning to identify the crucial engineering stages to enable concurrent engineering to take place."

Another issue was the need to design the topsides to support the drilling and completion campaign, which grew in scope and complexity as engineering progressed, resulting in a higher than normal complement of flowline connections for the wellheads (28, compared with 18 slots at the outset of the project). "That necessitated a proportional increase in piping, valves and instrumentation, which in turn led to increased steelwork to allow the structure to support this load. It meant that the whole structure had to be re-designed to achieve the minimum 10-year fatigue life requirement," Phelan added.

"We decided to use traditional structural reinforcements, not wanting to make the problem even worse," Phelan explained. "And our structural engineering team introduced weld improvements to make them more resistant to fatigue." Typically, Sea Swifts are constructed using standard welding procedures, similar to those applied for conventional jacket structures. Most of the structural welds are full penetration butt welds.

The four-deck WSS topsides will measure 14 sq m (150 sq ft) and weigh over 400 metric tons (441 tons) when fully laden. "The whole topsides arrangement is very crowded," Phelan said, "including all the regulation stairwells, walkways and personnel railings, all in accordance with API codes." Access must be provided to personnel coming from and returning to the MOPU (there is no temporary accommodation on the WSS).

"This design happens to be square because of the four supporting conductors, but other Sea Swift designs can have anything from three to six-eight conductors. In that case, the topsides would be either triangular or rectangular."

The team also had to pre-determine side impact loads the structure would need to withstand, generated by visiting supply vessels and other boat landings.

Picture book installation

The completed subsea structures and WSS topsides will be transported on a barge to the offshore location, 140 km (87 mi) east of Peninsular Malaysia, for installation by the Transocean jackupGalveston Key. Earlier this summer, the rig was at a shipyard in Singapore undergoing temporary modifications for the installation program, which needs to be completed in October, prior to the start of the local three-month monsoon season.

"Depending on the weather, installation of Sea Swift platforms generally takes four to five days," Phelan said. "We have devised the whole installation procedure, with story boards showing each stage of the process pictorially to the contractor." The subsea structures will be attached during installation of the four leg conductors, followed by setdown of the topsides. Offshore mating involves weight setting the topsides onto a 'no go' plate which is part of the conductor string. The topsides are then centralized to give a tightly socketed fit.

"Because of the growth in flowline numbers from 18 to 28 during the engineering phase, some of the topsides equipment will have to be installed in November, after the main platform installation. But these are relatively small-scale items,'" Phelan explained.

The MOPU will provide power generation, process systems and accommodation for personnel operating both these and the wellhead facilities on the WSS. Following completion and tieback to the MOPU, production will start this year, with 16 producer wells in service under the first phase. "There will be requirements to monitor the WSS for marine growth, cathodic protection, and general inspection of the subsea structures perhaps every five years, as the structure is designed for a 10-year fatigue life."

Aquaterra is currently performing FEED assignments for other operators. According to Phelan, one major company has commissioned studies for 10 Sea Swift platforms for marginal fields on 10 different offshore locations, all on a standalone basis. "Our client sees this as a highly efficient, short lead time solution," he added, "bringing potential savings on all 10 locations."