Terje Horn, Norsk Hydro ASA

Nils Arne Soelvik, ABB Offshore Systems Inc.

The world's first subsea water separation and injection system – the Troll C subsea sep-aration station (Troll-Pilot) – has been in operation for more than a year. The results of a year of operation have demonstrated the benefits in total capital investment, operational considerations, and remediation of topside proc-essing capacity problems to enable increased prod-uction.

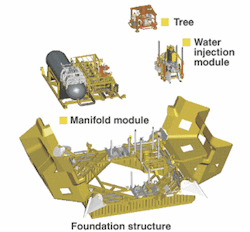

The Troll C subsea separation system is tied back 3.3 km to the Troll C platform in 350 m of water. The subsea station makes it possible to separate water from the wellstream on the seafloor and re-inject it into a low-pressure aquifer so that the water does not have to be transported back to the main platform. Eight wells can be routed through the processing station, which is designed to process four wells at a time, provided they are at normal production rates.

How it works

The Troll C subsea separation station was awarded to ABB under standard engineering, procurement, and construction terms. The transition from an extensive R&D effort to a normal commercial regime was rapid and challenging.

The main processing modules are the horizontal gravity-based separation vessel and the subsea water re-injection pump. A fully automated control system with separation level instrumentation and variable speed drive system provides the main functional blocks for control of the process system.

The wellstream is routed into the separator from one of the main production lines. Pre-processing is done in an innovative inlet mechanism called a low-shear de-gassing device. Its purpose is to split the gas and liquids to reduce the speed of the liquids and limit the emulsion formed. Once past the inlet device, the liquid is allowed to settle in the separator vessel, and the separated water is taken out directly to the water re-injection pump. From there, the oil and gas is commingled and forced back to the Troll C semi by the flowing pressure in the separator and pipeline system. The separated produced water is re-injected into the disposal reservoir by the subsea water injection pump via a dedicated injection well.

The water/oil interface is read by the level detection system, and the reading is fed back to the process controller topside via a fiber-optic communication system. The communication system calculates the required pump speed, feeds that data to the frequency converter that sets the pump speed, and the main loop of the process control is closed.

How it performs

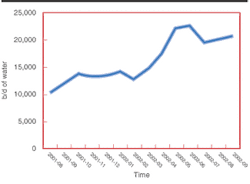

The primary purpose of the subsea separation station is to separate and remove as much water as possible, hence the injectivity and rate into the injection well is very important. At initial start-up, the subsea water re-injection pump was not installed and it was anticipated that the separation pressure would be sufficient to inject the water into the low-pressure reservoir. It soon became clear, however, that the pump was required to enable adequate injection.

Over the last year, the injection rate has gone up from 2,000 to 2,500 cu m/day to about 3,500 cu m/day, with occasional peaks of more than 4,500 cu m/day. This rate is about 60% of the rated capacity at maximum injection pressure. The required pressure at the water injection wellhead shows a downward trend. This trend is positive for the injectivity and indicates that the injection well completion and formation is capable of taking the inc-reased water production.

Another positive consequence of the improving injectivity is low power consumption for pumping the produced water into the reservoir. This reduces the energy cost per injected barrel of water and shows that there are substantial margins of the pump for later increasing water cut.

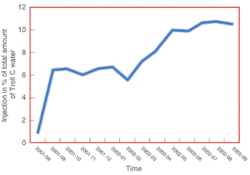

In the operation regime for the subsea separation system, the separator efficiency is measured by the amount of water left in the wellstream and the remaining oil in the produced water. Looking at the water in oil first, the system proves its functionality for total oil rates at or below the specified requirement of 4,000 cu m/day. When the system is producing up to 75% to 80% of the design oil rate, the amount of water in the oil is consistently in the range of 4% to 6% of wellstream volume. When producing at 100% oil rate, the water content reaches the maximum water-in-oil content of 10%.

The other performance indicator, oil in water, shows impressive results. The produced water quality is measured from ROV samples taken from a sampling point at the subsea processing station and brought back to surface for analysis. Over the last year, five samples have been brought back to surface and have shown results from 15 to 600 ppm. The last sample, 15 ppm, was taken when the subsea processing station was producing at 100% design liquid flow rate. To put this in context, the maximum oil in water limit for discharge directly to sea is 40 ppm.

The stable pressure and temperature in the separator, together with the performance results, demonstarate how quickly the process operators have been able to determine how to operate and maintain stable processing conditions. The Troll C subsea separation station has performed to specification and with nearly 100% availability. These results can be attributed to a combination of skilled operators, the robustness of the subsea processing system, and the emphasis Norsk Hydro has put on training and knowledge transfer.

Troll-Pilot has been a significant investment both for Norsk Hydro and ABB. Although the Troll C subsea separation station is a pilot, it is not a prototype or and extensive R&D test bed. It is considered a pilot in the sense that it is a first, but it has proven to be an investment in new technology that has and will generate payback for the operator. Significant achievements include:

- Over one year, 1 MMcm (6.3 MMbbl) of water have been injected from the subsea separation station. This corresponds to nearly 8% of all produced water from the Troll C semi. By increasing the water treatment capability, it has been possible to produce an estimated additional 400,000 cu m (2.5 million bbl)

- The environment benefits when the produced water is re-injected instead of discharged to sea

- Norsk Hydro and ABB have been able to make a system that performs beyond expectations at nearly 100% availability.