Well recompletion with ESP triples production for deepwater well

Limited only by the platform handling capabilities

Eric Niccum

BP

Randy McEntire

Sripriya Pulipaka

Baker Oil Tools

Dennis Butler

Centrilift

Production from a selected deepwater well in the Pompano field of the Gulf of Mexico initially doubled and after six months reached three times the orig-inal rate as a result of an electrical sub-mersible pump (ESP).

Most wells in the Gulf of Mexico are produced through gas lift. Once the gas loses natural pressure, the wells are considered depleted. BP decided to try to increase production by recompleting the Pompano well with an ESP to provide additional lifting capability.

null

A team made up of Baker Oil Tools and Centrilift engineers designed and installed an integrated ESP/packer system in the high-angle well to support an ESP at 7,700 ft TVD or 14,800 ft MD. After the initial success, this system also allowed BP to skip the gas lift production phase and go directly to ESP completion, which accelerated production and increased reserves. The ability to achieve multifold improvements in production through artificial lift suggests opportunities to apply the technique to wells with declining primary production in other areas of the Gulf of Mexico.

Discovered in 1981 at 1,300 ft water depth, the Pompano field straddles Mississippi Canyon block 28 and Viosca Knoll block 989 in the Gulf of Mexico. The well provided primary produc-tion of 2,000 b/d of oil, 2,100 b/d of water, and 2.5 MMcf/d of gas from natural flow. To accelerate production rates and access incremental reserves, BP decided to install an ESP for increased production through artificial lift. This was the first attempt to apply artificial lift to boost primary production for a well in the Gulf of Mexico. Gas lift mandrels were installed as backup for the ESP production.

System requirements

BP wanted flexibility in setting production levels through an ESP with a range of pumping rates. This capability was provided using a high-horsepower ESP motor with a variable speed controller. The ESP surface equipment, consisting of input and output transformers and a downhole monitoring system, was to be installed in a Class 1, Division 1 building on the platform deck. A 9 5/8-in. ESP packer was needed with 4,000-ft failsafe setting depth capability. Due to the high gas-oil ratio (GOR), the ESP packer required an annular vent safety system. An interventionless means was needed to sever the ESP cable and annulus vent valve control line, if it became necessary to remove the tubing independent of the packer.

The operator required delivery of an integrated ESP/packer system in less than 90 days from start of the project. For Centrilift designers, this was the first application of ESP for primary production in the deepwater Gulf of Mexico. The project team required personnel with expertise in both workover completions and ESP installation in a deepwater environment. A risk/reward package provided added incentive to complete the project on time, achieve flawless execution, and ensure a long run life.

Recompletion design

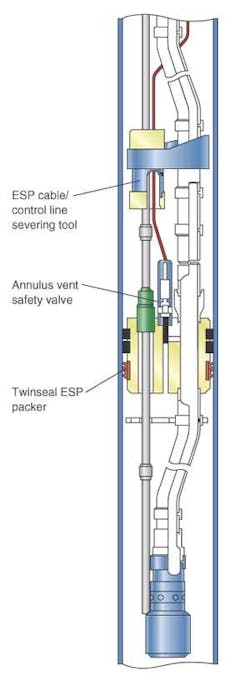

The team selected a twin seal ESP packer with an integral ESP cable penetrator and gas vent capability for the application. The team also designed a new 160-amp, 5-KV integral ESP cable penetrator for the twin-seal ESP packer and a new "VR" vent safety valve with 4,000 ft of failsafe setting depth capability. The need for a cable-severing tool came late in the planning process, necessitating a priority focus by engineering, manufacturing, and test lab departments. The design, prototype, testing, and delivery of two cable control line severing tools were completed in 24 days. The severing tool worked flawlessly in all four prototype tests.

The packer is designed to facilitate using a submersible electric pump. It can be provided with an integral ESP cable penetrator molded into the second string packer mandrel or with threaded connections to accept a pack-off power cable feed-through system with cable pigtails, or a drop-through penetrator. Addi-tional optional ports allow venting of gas through the annular vent, gas or fluid injection through the packer, and/or instrument wire port bypass. The packer has elements both above and below the slips. Rated to 5,000 psi at 275° F, the seals hold tubing force in tension and compression without affecting pack-off.

null

The US Minerals Manage-ment Service requires a safety valve for annulus production. The model VR vent safety valve is a control line actuated valve that attaches to the packer. On application of control line pressure, the valve opens and allows gas trapped in the annulus below the packer to vent to the annulus above. The VR valve has a fail-safe closed design. If the control line pressure is lost, then the valve automatically returns to the closed position. In the Pompano application, the vent provided the means to operate the contingency gas lift equipment installed above and below the packer. The valve has a fail-safe setting depth of 4,000 ft at the salt-water gradient in control line with a rated working pressure of 3,000 psi at 20° F to 275° F. The flow area through the valve is 1 sq in.

Severing tool

The ESP cable/control line severing tool is a mechanically-operated device designed to cut through the ESP cable and hydraulic control lines. The device is mounted to the production tubing string above the twin seal ESP packer and is activated in the event that the production tubing must be cut and retrieved independently of the packer.

It incorporates a tungsten carbide tipped severing blade and a unique grapple device that holds the cable and cuts both the cable and hydraulic control line as the tubing moves up hole after it is cut. The cut is made with minimal overpull and without the use of O-rings, sheave screws, or hydraulic lines. The tubing, ESP cable, and hydraulic control line above the cut are then retrieved from the well. All that remains is a small amount of cable and control line above the packer that can be removed by conventional means. There is no need for an ESP cable fishing job.

null

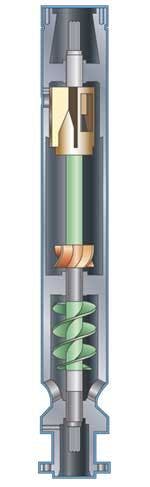

A 96-stage HC12500 ESP with a specially designed 675 series vortex gas separator was installed. The pump was powered by an HP 562 series motor with 675 seal and pump-mate downhole sensor package. A self-contained Class I, Division I control building to house the surface components on the platform was designed, built, and installed.

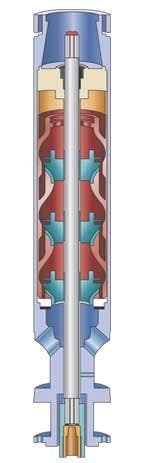

The pumps are multi-stage centrifugal with each stage consisting of a rotating impeller and a stationary diffuser. The rotating impeller adds velocity to the fluid stream by centrifugal force and tangential redirection at the impeller outside diameter. The stationary diffuser converts this high-velocity energy to pressure energy as it redirects the flow to the next impeller.

Impellers are made of corrosion-resistant Ni-resist for prolonged life; they can operate efficiently in a 10% free gas environment without the use of a gas separator. Diffusers of Ni-resist also act as a bearing surface, providing additional stability to the drive shaft. The sleeved drive shaft is made of K-Monel to afford both mechanical strength and resistance to corrosion.

The vortex gas separators can separate up to 90% of the free gas in a fluid stream and return it to the wellbore. The vortex separator directs the fluid stream into a rapidly rotating motion, or vortex. This action forces the liquid stream to the outside of the separation chamber while the lighter gassy stream stays near the shaft. This gas separator is appropriate for many moderately gassy applications and is especially effective in abrasive environments.

The combination of the Vortex gas separator and the VR vent safety valve has allowed 6-8 MMcf of production up the annulus, basically allowing the ESP to handle the high GOR production.

Downhole monitoring

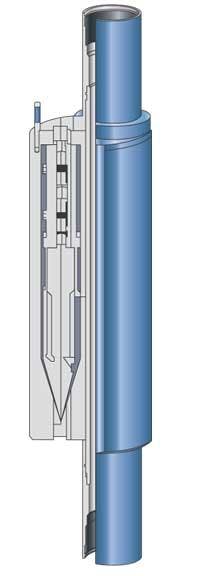

A downhole monitoring tool for use with the ESPs, the PumpMate system monitors motor temperature, well temperature, pump intake pressure, and insulation integrity. It is installed on the bottom of the ESP motor and communicates to the surface via the ESP power cable.

null

Control building

Built to fit the space constraints of the platform, the Class I, Division I building holds the 1,000 KVA variable speed drive, 1,000 KVA input and output transformers, disconnect switchgear, fire and gas junction box and marshalling box. The rig crane lifted the 30,000-lb unit in a single lift and placed it in the prefabricated stand.

Installation process

The assembly consisted of the ESP pump and the twin seal packer with splices below and above the packer. As some of the items, such as the cable severing tool and annular VR safety valve, did not exist before this project, every effort was made to prototype and test all aspects of the equipment design and installation plan within the tight one-month time frame.

null

The ESP installation process on the rig floor began with picking up of the lower tandem motor assembly with the attached PumpMate monitoring system and centralizer. This was followed by picking up of the upper tandem motor and the seal section. Electrical checks were performed to verify system integrity. The separator lower, middle, and upper tandem pumps were then assembled. The handling sub was installed in the head of the upper tandem pump and the complete assembly was raised to splice the motor lead cable to the well cable. After continuity and function tests, the assembly was ready for downhole installation.

After running in with the ESP assembly and tubing, the twin seal packer was made up with cable splices below and above the packer. A 1/4-in. hydraulic control line was attached to the VR vent valve at the top of the packer to test the control line connection to 10,000 psi for 15 min and function test the valve. This was followed by the installation of the cable-severing tool. After completion of surface electrical connections and testing, the ESP was ready for operation.

After the ESP installation, the well production reached 4,900 b/d of oil, 5,000 b/d of water, and 4.6 MMcf/d of gas, double the previous rate. Six months later, the production reached three times the original rate and is limited only by the platform handling capabilities. This successful application of ESP to boost primary production in the Pompano field has prompted preliminary studies for other wells in the Gulf of Mexico with declining production.