Executive insights: Remote operations are evolving with ROV/AUV advancements

Editor's note: This story first appeared in the May-June 2023 issue of Offshore magazine as part of the Remote Inspections & Operations Special Report.

By Ariana Hurtado, Editor and Director of Special Reports

Remote operations is a big area for Oceaneering, with established facilities for remote operations in Norway, Aberdeen and along the Gulf of Mexico (GoM). Oceaneering has carried out remote commissioning, remote pipeline pigging, remote survey and rig positioning, and remote inspections.

Earl Childress, Oceaneering's senior vice president of business development and chief commercial officer, shared insights with Offshore about the evolution of remote operations, the disadvantages and challenges of remote ops, remote commissioning, R&D, automation capabilities, offshore wind remote ops, and the state of the offshore energy industry.

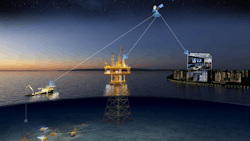

"Remote operations are continuously evolving to address challenges in the offshore energy industry by increasing efficiency, reducing costs, minimizing risks and lowering the environmental impact of operations," he said. "Technological advancements play a crucial role in these improvements. Some notable recent advances include improved connectivity and communication, such as high-speed networks (4G LTE and satellite connections), which have enabled better communication between onshore and offshore personnel, allowing for smoother remote piloting and real-time collaboration."

He listed several other examples of technology advances, including onshore remote operations centers, which are dedicated facilities that act as operational hubs for remote piloting activities and that he said are enhancing efficiency and collaboration between teams.

Resident robotic systems, such as Oceaneering’s Liberty E-ROV, reduce the need for support vessels and offshore personnel, resulting in cost savings and reduced carbon emissions, he added.

"In the asset inspection and integrity management space, the ability to collect data with drones, quadbots and sensors (for image, rotating information, gas, temperature, material deterioration) is improving with great speed," Childress said, offering another example of a notable technology advancement. "These things, combined with improvements in software and the use of artificial intelligence [AI] and machine learning to process data, are delivering impressive results, such as the integration of new technologies tested onshore for subsea like stress concentration tomography in ROVs.

Challenges

While there are numerous advantages of remote operations for offshore oil and gas projects, there are also some challenges that offshore oil and gas operators face.

Childress listed latency and network reliability being one of the disadvantages. "Remote operations depend on reliable and low-latency communication networks. In areas with poor connectivity or high latency, remote operations can face difficulties," he explained. "Oceaneering addresses this challenge by working with operators to provide the required communication networks, using LTE, geosynchronous satellites or low earth orbit satellites, to ensure reliable connectivity."

He also listed IT security as a challenge. "Secure communication between onshore and offshore personnel is crucial to protect sensitive data and maintain operational integrity," he said. "Oceaneering has developed robust IT security measures and fail-safe systems to overcome potential cybersecurity threats and maintain secure communication channels."

Lastly, Childress said a resistance to change can be another setback. "Traditional offshore operations might be hesitant to adopt remote piloting due to concerns about reliability, safety and operational efficiency," he said. "Oceaneering works to build confidence in its remote piloting capabilities by showcasing our extensive track record, redundancies and offshore control measures."

Offshore oil and gas operators face a variety of remote operations challenges that can vary by region and environment. According to Childress, some of the most common challenges include infrastructure limitations, regulatory compliance and harsh environments, and other issues may include integration with existing methodologies and adoption of new techniques.

"Today, the crews conducting remote operations have prior experience working in a physical offshore environment. In the future, we may see crews that have never been offshore or only have limited experience," he suggested. "This could introduce a future operational risk where the crews become more disconnected from the operations. Therefore, new training programs will be needed to address the adoption of new technology and the new way of working."

Regarding infrastructure limitations, remote operations require reliable communication networks, which may be limited in certain areas. "Solutions include investing in communication infrastructure, such as satellites and subsea communication cables, to ensure stable connectivity regardless of location," Childress said.

As for regulatory compliance, different regions have specific regulatory requirements for offshore operations, including remote operations. "Ensuring compliance with these regulations is a significant challenge," he said. "Solutions involve staying updated on the latest regulatory updates, collaborating with local authorities and implementing technology that adheres to regional requirements."

Additionally, offshore oil and gas operations in regions like the Arctic, the North Sea and the GoM face extreme weather conditions, which can hinder remote operations. "Solutions include developing specialized equipment and tools designed to withstand these conditions, implementing real-time monitoring systems and using advanced analytics to optimize operations and minimize downtime," Childress said.

Remote commissioning ROV

The company'sLiberty E-ROV resident vehicle has performed numerous subsea production systems commissioning tasks as part of its regular operations.

"Liberty performs commissioning by remote operations without needing the installation vessel to stay on station for the full commissioning operation," Childress explained. "Liberty has its own battery pack, subsea garage and communication buoy allowing it to stay subsea for longer without support."

It also helps with decarbonization strategies. A conventional ROV will emit 644 metric ton of CO2 on an average 14-day inspection, maintenance and repair campaign, but the Liberty E-ROV by contrast will emit 178 metric ton of CO2 over the same time period, saving approximately 466 metric ton of CO2.

"ROVs do not directly emit CO2, instead they draw power from the vessel used for the offshore campaign," Childress added. "The Liberty E-ROV draws power from its battery pack and reduces a typical IMR campaign’s dependence on support vessels to help save 33 MT per day of CO2.”

As of April 20, the Liberty E-ROV has completed 163 missions and almost 14,000 operational hours. It has eliminated 10,000 support vessel hours or roughly 400 vessel days, thereby eliminating 19,000 tons of CO2 emissions by eliminating the need for the support vessel to stay on station while the ROV works. By bringing workers back to shore, Oceaneering's remote operations have eliminated 240 personnel crew changes (12-hour shifts over 14-day trips).

Liberty also assists with decommissioning tasks, and the resident vehicle recently conducted a remote subsea pipeline isolation for a major North Sea operator.

"Traditional pipeline isolation programs call for an onsite support vessel for most of the work," Childress said. "However, Liberty does not require one to stay on station. For this operation, a remotely controlled high-pressure, piggable isolation tool was selected, which allows pipeline isolation without requiring the system to be fully evacuated. Liberty tracked and monitored the pigging tool’s position as it navigated the pipeline."

Operations were monitored from an Oceaneering onshore remote operation center in Stavanger, Norway, and the operator was able to save eight vessel days, reducing carbon footprint and realizing cost savings.

On the technology horizon

"Oceaneering is continuously working on developing innovative ROV and subsea robotics technologies to enhance their capabilities and efficiency," Childress said. "One such project is the Virtual Command Center (VCC), which provides a centralized and real-time digital twin for all Oceaneering's assets related to remote operations."

The technology horizon for Oceaneering, he continued, also includes advancements in AUVs, AI and machine learning as well as augmented reality (AR) and virtual reality (VR). For instance, Oceaneering is in the R&D stage for advanced AUVs capable of operating independently or in tandem with ROVs to perform complex subsea tasks, such as pipeline inspections and seabed mapping.

"Leveraging AI and machine learning technologies, Oceaneering aims to improve the efficiency and reliability of ROVs and subsea robotics, enabling them to perform tasks with increased precision and accuracy," he added. "Integrating AR and VR technologies into the VCC and other remote operations systems can provide operators with immersive and interactive experiences, facilitating better collaboration, decision-making and problem-solving."

Automation

So, how is electrification and digitalization enabling automation capabilities and enhancing remote operations workflows?

Childress said, "Electrification and digitalization are driving forces behind the enhancement of automation capabilities and remote operations workflows in the offshore energy industry. These advancements enable subsea resident vehicles, including fully remote-controlled or autonomous vehicles, to perform tasks more efficiently, accurately and with reduced environmental impact."

He named several ways that electrification and digitalization contribute to these improvements:

- Enhanced communication: Digitalization allows for high-speed, real-time communication between onshore control centers and subsea resident vehicles. This improved connectivity enables remote operators to monitor, control and receive feedback from underwater equipment more effectively, reducing the need for onsite personnel and allowing for more informed decision-making.

- Improved data collection and analysis: Digital sensors on subsea resident vehicles collect vast amounts of data during operations. Advanced data analytics and machine learning algorithms can then process these data to identify patterns, trends and anomalies, providing valuable insights for optimizing operations and maintenance schedules.

- Increased energy efficiency: Electrification of subsea equipment reduces reliance on hydraulic systems and enables the use of more energy-efficient electric actuators. This results in lower energy consumption, reduced operational costs and minimized environmental impact.

- Greater automation: Digitalization enables the development of advanced control systems that can automate many aspects of subsea operations. Autonomous subsea vehicles can perform tasks independently, while semi-autonomous vehicles can be controlled remotely with minimal human intervention, increasing efficiency and reducing the risk of human error.

Offshore wind remote ops

Oceaneering released its high-speed, high-current capable Isurus ROV in 2019 with offshore wind and renewables projects in mind, and the fifth and sixth Isurus vehicles were released in 2022.

"Based on our proven Magnum ROV, the Isurus features a more hydrodynamic design allowing it to maintain position in challenging weather conditions, extending operating windows," Childress said.

The company has worked in Europe and Asia for renewables customers since 2021.

CEO Rod Larson said in October 2022 that the industry is in an "offshore resurgence" and Childress added to this idea, sharing his own perspective on the state of the offshore energy industry.

"I believe that there is a durable upcycle in traditional energy with growing opportunities in renewable sources of energy and carbon capture," he said. "We are exploring additional opportunities through a new strategic agreement, announced in late January this year, with Kontiki Winds, a Havram company, to jointly pursue the application of floating offshore wind for remote microgrid renewable power generation to electrify offshore assets such as oil and gas production as well as other small scale power generation opportunities."

Offshore energy transformation

"A balanced approach to energy will ensure energy security for the most vulnerable populations and ensure that no one gets left behind as renewables gain traction and build infrastructure," Childress said.

He added that the path forward involves a combination of technological innovations, regulatory changes and industrywide collaboration, which include

- Increased focus on energy efficiency and emissions reduction: Offshore operations should prioritize implementing measures to increase energy efficiency and reduce emissions. This may include electrification, digitalization, automation and remote operations.

- Collaboration and knowledge sharing: Industry stakeholders, including operators, service providers, technology developers and regulators, need to work together to share knowledge, best practices and innovative ideas. This collaboration can help accelerate the adoption of new technologies and drive transformative change in the offshore energy sector.

- Supportive/stable regulatory environment: Governments and regulatory bodies must develop policies and frameworks that encourage and support the transition to cleaner, more sustainable offshore energy operations. This may include incentives for renewable energy development, emissions reduction targets and stricter environmental regulations, along with stable policies around hydrocarbon development.

- R&D investment: Continued investment in R&D is crucial for driving innovation in the offshore energy industry. This should include the development of new technologies (e.g., advanced robotics, AI and machine learning applications) that can improve the efficiency, safety and sustainability of offshore operations.

- Workforce development and training: As the offshore energy industry evolves, so must the workforce. Industry stakeholders should invest in training and development programs to ensure that employees have the necessary skills and knowledge to operate and maintain new technologies and processes.

"By focusing on these aspects, the offshore energy industry can transform itself into a more sustainable, efficient and environmentally responsible sector, capable of meeting the energy demands of the future while minimizing its impact on the planet," he concluded.