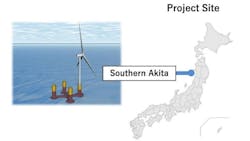

Floating wind substructure project targets start-up offshore Japan in 2029

EXCLUSIVE CONTENT:

Japan Marine United Co. (JMU) has launched a floating offshore wind substructure initiative.

The Southern Akita Floating Offshore Demonstration Project has secured financial support under the New Energy and Industrial Technology Development Organization’s "Cost Reductions for Offshore Wind Power Generation" development.

A consortium consisting of nine companies led by Marubeni Offshore Wind Development will collaborate to install two wind 15 MW+ turbine generators (WTGs) around 25 km from the coast of southern Akita Prefecture, in a water depth of around.

The project will continue through March 2031, with the demonstration wind farm set to start operations in the fall of 2029.

To date, JMU has performed R&D into cutting the cost of fabrication and installation of floating substructures using an in-house semisubmersible floating substructure design.

For the new program, R&D will focus on the following seven themes:

- Establishing afloat joining technology at sea to allow for mass production of floating substructures: As WTGs scale up in size, floating substructures will also become larger, with limited options for construction of an entire floater in one piece. JMU’s solution is to join split-building blocks of the floating substructure offshore.

- Optimized construction methods: The floating substructure design is said to be suited to fabrication by yards that work on steel structures such as ships and bridges. Through an alliance with those yards, JMU will gather hull blocks, fabricated concurrently in separate yards, at one site for joining at the sea.

- Improved transportation of floating substructures transportation through minimizing temporary wet storage: The aim is to devise a method for transporting mass-produced floaters to the WTG integration port simultaneously and a preparatory arrangement pre- and post-integration of WTGs to minimize downtime-related costs

- Improved availability of work vessels and crew transfer vessels (CTVs): weather downtime restricts the window of offshore construction activities. JMU will seek to develop a more efficient mooring installation method and assess of CTVs during operations and maintenance.

- Establishment/standardization of analytical methods for large floating substructures: as WTGs get larger, the natural frequency of the substructure and the WTG can interfere with each other. Present design methods are said to be insufficient for analyzing the effects of wind loads to avoid the interference.

- Optimizing the cost of hybrid mooring in deepwater areas: JMU will develop a taut/semi-taut hybrid mooring for this process, including procurement and installation.

- Digitalization: Use of digital twin systems that can monitor structural soundness from onshore bases to improve power production and operational lifetime.