US East Coast steel plant, tower fabrication facility to service offshore wind market

Offshore staff

PELHAM, New York — US Forged Rings Inc. (USFR) has made a $700 million investment in the US offshore wind industry to construct a tower fabrication facility and a steel forging plant.

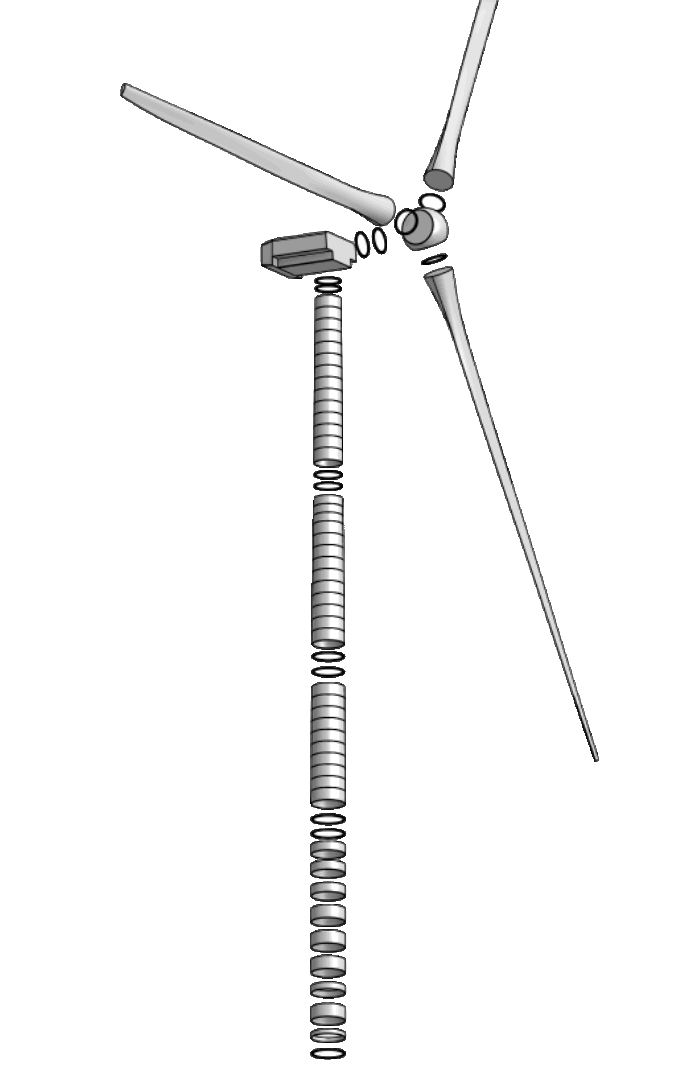

The company said it will use these two facilities to service the growing domestic offshore wind market, filling a critical supply chain gap for offshore wind components and alleviating bottlenecks for a market with goals of deploying 30 GW by 2030 and 110 GW by 2050.

The company is in final stages of evaluating East Coast locations and expects to announce a decision soon.

Once operational, the tower fabrication facility will produce 100 fully coated towers annually, which include internally produced flanges, eliminating potential delays and logistics issues, lowering the overall cost. The facility is designed from its inception to be expandable up to 200 towers annually, depending on demand. The new steel forging facility will produce large flanges up to 40 ft in diameter, making it the largest ring rolling facility in North America and Europe, according to USFR.

Once all permits and regulatory approvals are secured, construction of the facilities is expected to take 16-20 months, with first towers beginning production in first-quarter 2026.

“We are currently in the final stages of evaluating several potential locations on the East Coast,” said Slavko Zurovac, USFR’s managing director. “All potential sites are strategically positioned with access to required waterways, rail and utilities, providing significant logistical benefits and making it competitive to supply large components.”

The two facilities will create more than 500 US full-time employment positions and will limit carbon footprint by utilizing 77% recycled content.

Through its supply chain partnerships with steel producer Nucor and ingot caster Ellwood Quality Steels, USFR said it aims to produce final products that are 100% made in the US.

02.07.2024