Better data will lead to better decisions

T.Guidry

A.Elfaki

T.Meche

R. Huval

R.Coleman

D.Leger

J.Leblanc

Core Laboratories

Reservoir fluid pressure-volume-temp-erature (PVT) studies are nothing new to reservoir engineering. In fact, PVT labs have been around for 50 years or more. They provide a window into the future behavior of hydrocarbon systems by physically simulating reservoir depletion and surface recovery.

PVT reports have evolved with the growth of computing and word processing methods, but PVT experiments themselves and the theory behind them have basically remained the same for 50 years, although improvements in accuracy have followed improvements in technology. Extracting properties such as formation volume factor (FVF), viscosity, and solution gas-oil ratios is relatively easy, even in large reports, but many of these properties are inter-related and must all follow the laws of thermodynamics.

Material balance techniques

PVT tests are physical simulations of reservoir depletion, usually by flashing initial reservoir fluid to ambient conditions, yielding residual oil and a volume of evolved gas. Different fluid types are simulated by different depletion "paths." However all types yield atmospheric liquid and varying flash gas volumes at the test's conclusion.

When a sample is charged to a PVT vessel, the system becomes a mini-reservoir of sorts and can be treated as such. Just as engineers perform material balance calculations on reservoirs to determine reserves and recoveries, similar material balances can be calculated on PVT experiments.

With the obvious advantage of already knowing what is in place initially, the percent error can be calculated. The foundation for the basic material balance is "what goes in must come out." A detailed comparison of the mass of the initial fluid should equal, within reason, the total mass of the combined flash products. An error of +1% is acceptable for the mass and molar balances of a PVT study. Knowing actual experimental masses is unnecessary, as PVT reports provide all data necessary to calculate these balances, starting with a few logical assumptions.

Fundamental assumption

Again, the comparison is the mass of the single-phase fluid at the start of the test with the resultant combined mass of the produced and/or residual products at the conclusion of the test. To start the calculations, the fundamental is a residual oil volume of 1 bbl after the completion of the experiment. This assumption makes the other volumetric and mass calculations, using the reported data, relatively simple.

By definition, the formation volume factor is the volume of oil at reservoir pressure and temperature relative to a residual barrel at ambient conditions. Therefore, the assumption of 1 bbl of residual oil defines the volume of oil initially as the unit formation volume factor at the pressure of reference. The difference in the volume and mass of these two values is the gas evolved during the depletion of the fluid from the respective saturation pressure to atmospheric pressure.

With the assumption of 1 bbl of residual oil, the volume/mass of liberated gas becomes the solution gas-oil ratio reported at a respective pressure. In the case of 6,326 psi, assuming 1 bbl of residual oil defines the volume of oil at 6,326 psi as 1.329 bbl and the liberated gas volume/mass as 795 scf. At any pressure reported, the mass of 1 bbl of oil combined with the mass of the solution gas shown are equivalent to the mass of the initial volume (unit FVF), calculated using the oil density at that respective pressure. Intuitively, the initial oil of 1.329 bbl is equivalent to the combined solution gas (795 scf) and residual oil (1 bbl) from a mass and molar standpoint. Most PVT reports show "cumulative" solution gas gravity, which is a weighted average of the entire evolved gas volume. If this value is not reported, then it needs to be calculated using the summation of the incremental gas gravities and liberated gas volumes as weights.

Molar balance

A molar balance should also be calculated. The mass of a fluid divided by its molecular weight yields the moles of fluid. A molar balance combines the mass balance with a QC of the associated compositional analyses performed on the samples, since the molecular weights are normally derived from compositional analyses, such as chromatographic analysis.

It is possible for the mass balance to match and the molar balance to have a significant discrepancy (5% or more). This is usually caused when unrepresentative molecular weights are used, which are normally calculated with chromatographic data. If the reservoir fluid mole weight is calculated correctly and the associated residual liquid and cumulative evolved gas mole weights are accurate, then the molar balance will be in agreement with the mass balance.

Compositional balance

A more detailed compositional balance can also be calculated. The reservoir fluid composition is normally calculated by a mathematical recombination of the flash products from a single stage flash test of the initial reservoir fluid. Residual gas and liquid compositions are mathematically mixed together based on the molar gas-oil ratio observed from the flash test.

Individual differential liberation gases can be combined with the residual liquid to re-calculate the reservoir fluid. This reservoir fluid can be directly compared to the "reported" composition from the single stage flash mentioned above. This yields two distinct methods and measurements of the reservoir fluid composition. If these two compositions show significant variations, problems exist in either the compositions themselves, the experimental volumes measured, or the balances discussed earlier.

If any of the three balances described here are in error, normally errors are seen in the other two as well.

Potential problems

Assuming these material balances are within acceptable tolerances, there can still be problems. For example, suppose your report shows a reservoir fluid single stage flash test with a gas-oil ratio of 1,000 scf/bbl and a reservoir fluid 3-stage flash test, at the same temperature, with a liberated gas-oil ratio of 1,100 scf/bbl. In addition, the residual oil gravities are 31° API and 32° API, respectively. The material balances may match perfectly, but with black oils, it is not physically possible for a multi-staged separator test with the same temperature stages to yield a higher liberated gas volume than a single stage test. The effect of staging is to minimize the volatility of the flash, giving increased steady-state retention time. This action minimizes gas evolution, yielding lighter residual oil and lighter evolved gas. Oil gravities can also indicate a possible problem, where the expected trend is "reversed" as compared to the gas-oil ratios.

Flash comparison

The flash comparison is a powerful indicator of the validity of the data. The idea is relatively simple. Assume three distinct but equal reservoir fluid sub-samples – A, B, and C – all having the same composition and all equilibrated at the same initial conditions. Sample A is used in a single stage flash test to 0 psig and ambient temperature. Sample B is used for the differential liberation, that is, a 5-stage flash test performed at reservoir temperature to 0 psig and reservoir temperature. Sample C is used to perform a 3-stage separator test through a set of proposed field separator conditions (1,000 psig and 100° F, 150 psig and 90° F, 0 psig and 60° F).

Initially, all samples would be equilibrated at reservoir conditions, then flashed through their respective tests. Flashing the same reservoir fluid through three paths yields three sets of residual fluids and recoveries and provides the basis of our comparisons.

Keep in mind that these three distinct sets of residual data all have a material balance equivalent to the same initial reservoir fluid. Differing gas-oil ratios are compensated by different gas and liquid gravities and compositions, but specific rules must apply to these flashes.

The flash test that yields the highest liberated gas-oil ratio must also have the heaviest residual liquid and heaviest cumulative gas density. This flash also yields the highest shrinkage. The flash yielding the lowest gas-oil ratio shows the opposite characteristics.

Process dynamics

As the pressure depletes, the fluid evolves more gas. The gaseous phase, therefore, is becoming heavier, because the lighter components of the reservoir fluid are the first to be liberated. As more gas is liberated, more of the heavier components are released into the vapor phase.

Conversely, if the lightest components of the oil begin to flash, the remaining liquid is becoming heavier. As more gas is liberated, less liquid is recovered due to increased shrinkage. Theoretically, the highest gas-oil ratio always yields the heaviest gas, heaviest oil, and highest shrinkage factor or formation volume factor.

In general, a staged flash minimizes this gas evolution and never yields a higher gas-oil ratio if performed through the same temperatures as a single-stage flash. However, with elevated temperatures, it is possible to have a higher gas-oil ratio from a staged flash, such as the differential liberation as compared to the single stage. If reservoir temperature is hot enough, excess gas can be "cooked" off and overcome the staging effect. With this in mind, there is no steadfast rule regarding whether the differential liberation test or the single stage test will yield the highest ratio. It can only be said that which-ever test does, the other consequences must also follow.

Almost certainly, the multi-stage separator test through separator conditions will yield the lowest gas-oil ratio of the three. The possible scenario that might be caused otherwise would be the rare case where the separator temperatures are approaching reservoir temperature and the differential liberation has more stages.

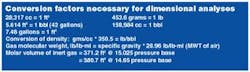

Equations:

(1) Density of reservoir fluid, in lbs/bbl = density (gms/cc) * 350.5 (lbs/gms * cc/bbl)

(2) Mass of initial reservoir fluid, in lbs = FVF (bbls)* density (lbs/bbl)

(3) Mass of residual liquid (1 barrel), in lbs = residual oil density (gms/cc) * 350.5 (lbs/gms * cc/bbl)

(4) Mass of evolved gas, lbs = solution GOR (SCF) * MWT (lbs/lb-ml)/ molar volume (ft3/lb-ml)

(5) Mass of flashed reservoir fluid combined, lbs = mass of residual liquid + mass of evolved gas

Conversion factors with equations become:

(1) Density of reservoir fluid, lbs/bbl = 0.779 * 350.5 = 273.04 lbs/barrel

(2) Mass of initial reservoir fluid, lbs = 1.329 * 273.04 = 362.87 lbs

(3) Mass of residual liquid, lbs = 0.920 *350.5 = 322.46 lbs Gas molecular weight = 0.652 * 28.96 lbs/lb-ml (MWT of air)= 18.88 lbs/lb-ml

(4) Mass of evolved gas, lbs = 795 SCF * 18.88 lbs/lb-ml / 371.2 ft3/bl-ml = 40.44 lbs

(5) Mass of combined residual products = 322.46 lbs + 40.44 lbs = 362.90 lbs Mass "in" = 362.87 lbs, Mass "out" = 362.90 lbs, Percent error < 0.1%

If the PVT reports do not show 'cumulative' solution gas gravity, then it needs to be calculated using the summation of the incremental gas gravities and liberated gas volumes as weights.