Richard Martin

London Marine Consultants

There are many variables when designing mooring systems for FPSOs and FSOs. These include the purpose of the vessel, water depth, environmental conditions, jurisdiction, vessel size, number of risers, project duration, operator preference, and budget.

The first decision is whether or not a “spread mooring” can be adopted, in which an array of mooring lines restrict the vessel from rotating. The other most commonly used system is “turret mooring,” which permits the vessel to weathervane in accordance with prevailing waves, winds, and ocean currents, thereby reducing the overall mooring forces.

Weathervaning and the swivel stack

In all turret mooring systems there is a structure (the turret or geostationary part) with a vertical axis linked to anchors on the seabed via the mooring lines. Flexible risers connected to wells or manifolds on the seabed transfer fluids or gases onto (or off) the turret and hence into piping on the FPSO.

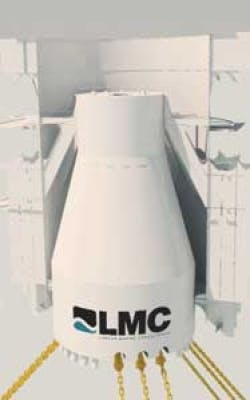

Since the FPSO can weathervane with the environmental conditions, fluid swivels must be mounted on the turret concentric with its axis, to allow the products to pass while the vessel weathervanes. These swivels have to withstand well pressures and must be reliable, with several back-up seals. For this reason a swivel stack for an FPSO is expensive, often equivalent to the combined costs of the seabed anchors, chains, and the turret structure. If there is only one fluid swivel plus some utility swivels, which is the norm for an FSO, the cost is much lower. So the cost of the swivel stack often affects selection of the mooring system.

Spread mooring systems

The system chiefly involves welding fairleads and chain stoppers to the deck of the vessel and running mooring chains, wires, or ropes from these stoppers to pre-laid seabed anchors, driven piles, or occasionally to suction piles. Products flow onto the FPSO via flexible risers connected to a riser balcony close to midships. Sometimes the FPSO can be moored close to a platform with jumper hoses between the two, as illustrated by the Talisman FPSOAngsi, on which LMC was one of the designers. In this case there is even an articulated bridge connection to the platform. The cost of outfitting a vessel for use with a spread mooring normally is less than for turret moorings and there is no need for a swivel stack, which is a big cost saving for an FPSO.

Assessing whether or not a spread mooring is practical depends largely on the 100-year extreme conditions at the field. It is not just the highest sea state that matters but distribution of extremes by direction. For example, it may be feasible to use a spread mooring where there may be a seastate from one direction of Hs=7 m (23 ft) and a seastate of 4 m (13 ft) from other directions, but difficult to design one for Hs = 5 m (16.4 ft) from any direction.

In some cases, while it may be feasible to design such a configuration, the number of lines and their size can make the spread more expensive than a turret mooring system. For example, 24 mooring chains may be required for a spread mooring system, but only nine for a turret mooring at the same location because the mooring forces are reduced when using a turret, due to weathervaning.

Also, with a spread mooring it is more difficult to offload to an export tanker, with increased risk of collisions between the two vessels. So these and other issues must be weighed against the cost of the turret and its swivel stack. On two occasions, LMC has provided spread mooring systems using the tanker’s own winches and wires (zero conversion cost), for short-term use, with low cost implications. Typically, however, spread moorings are best suited to locations off West Africa, Brazil, and also parts of Indonesia, Malaysia, and the Arabian Gulf.

External turret – cantilever type

Here a structure is welded to the bow or stern of the vessel, with a chain table suspended from it via a slewing bearing. The mooring chains are connected to the chain table with a swivel or swivel located above the chain table. The design for M3energy’s FSO on CPOC’s JDA block B-17 in Southeast Asia is one of five LMC turrets of this type. This is the simplest and cheapest form of turret mooring, very compact and efficient, and the first choice, where possible. Designers have accommodated up to 21 risers and it has been used where conditions are up to Hs = 10 m (32.8 ft).

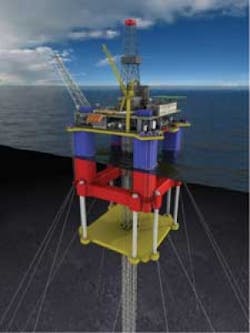

External turret – column type

A lesser number of FPSOs and FSOs are equipped with a turret which may be referred to as the “column type.” These have been provided only by SBM and by LMC. The chain table is welded to a vertical column which is suspended via a slewing bearing from a cantilever, this being welded to the bow, near the main deck of the FPSO.

A further structure, welded to the bow, surrounds the column and contains plain bearings which carry the main component of horizontal loads imposed on the FPSO by the mooring system. In the LMC design, the upper and lower cantilevers are united by an outer column. This allows the turret to be fully commissioned before mounting it on the FPSO, so the turret can be fabricated independently of the hull.

The lower plain bearings can be designed to carry high loads. These designs have more potential for adoption in harsh environments than cantilever turrets. The existence of the external column reduces the moment imposed on the slewing bearing at the top of the column. It is normally these moments which are the main limitation on the capacity of the slewing bearing, not the loads acting axially and radially to the bearing. One example is theFarwah FPSO which has been in production offshore Libya since 2002. With this design, the swivel stack is not too big and is protected within a housing from possible green water impact.

Two similar larger turrets designed by LMC are under construction at Dubai Drydocks. One is for Saipem’s newAquila FPSO off southern Italy for operator ENI. The other is for Saipem’s Livorno OLT FSRU in the Adriatic Sea, the world’s first permanently connected FSRU (Floating Storage and Regasification Unit), on which LNG will be converted to gas for export via risers connected to the turret.

The FSRU is a converted gas carrier, so introducing an internal turret would have been difficult. LMC considered a cantilever turret, but such a design would have had to be integrated with existing steelwork at or near the main deck level, and these scantlings are light on an LNG carrier.

Fabrication of these structures is more difficult, compared to a cantilever turret, because of the need for exact alignment between the upper and lower bearings. Also, the weight of the structures totals around 500 metric tons (551 tons), which is about 150 metric tons (165 tons) more than a cantilever turret.

Internal turrets

In harsh environments, or where over 15 risers are to be accommodated, an internal turret may be required. This provides good, safe access to the swivel stack and can be designed to almost any diameter to accept the forces and the risers. The turret normally is located no further aft than one- third of the vessel length.

The principles by which the mooring forces are transmitted are the same as those for the external column turret. The top bearing may be a slewing bearing, bogies, or wheels (as on an offshore crane). LMC is experimenting with rollers instead of wheels, a principle that has been applied on warship gun turrets. The bottom bearing has discrete pads bearing on an Inconel surface.

LMC has designed the internal turret for theEMAS LEWEK FPSO, for Premier Oil Vietnam Offshore, currently undergoing conversion from a tanker at the Keppel Benoi yard. This is a strong technical solution, but normally costs a lot more than an external turret. Also, the vessel conversion is more substantial, takes longer to complete, and involves time in dry dock.

Less common alternatives

Over the years, a wide range of other systems have been used. Many are derivatives of systems used for loading and offloading trading. Those involving complex articulations between the vessel and the mooring are now less frequently selected. They include:

- Articulated columns and SALMs (Single Anchor Leg Moorings) in which the mechanical parts, including fluid swivels, are on the seabed and therefore less accessible

- Floating columns with articulations between the vessel and the top of the column

- Fixed towers to which the vessel is connected via a frame with articulations (although sometime these may be a good solution in water depths of less than 35 m, or 115 ft)

- CALRAM (Catenary Anchor Leg Rigid Arm Mooring) and similar systems in which a buoy, with a turntable, is connected to the vessel either via chains or via articulations. These can also be suitable in situations where riser design is difficult

- CALM (Catenary Anchor Leg Mooring) buoys are used sometimes to moor FSOs, but not FPSOs because of the difficulties of supporting and maintaining high pressure swivels on the buoy. Also, the possibility of the vessel colliding with the buoy has to be considered. Derivatives of the “admiralty” mooring are also employed, but these present limitations regarding free weathervaning and can become complicated when there are several risers.

So far, no two systems have been the same for any offshore projects, due to all the variables.