In the near offshore area of Cabinda, Angola in West Africa, dozens of small platforms illustrate the size and complexity of the greater Takula oil and gas field. The field is operated by Chevron for the Cabinda Gulf Oil Company (CABGOC) which is a partner ship between Sonangol, Agip, Elf, and Chevron. Production is piped to shore and refined at Chevron's Malongo camp.

The Takula facility located offshore Cabinda, Angola.

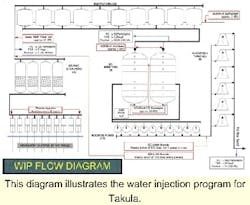

In this near-shore area, there are 17 platforms pumping production created by the world's largest offshore seawater injection program. The Water Injection Plant (WIP) moves an average of 490,000 bbl of seawater per day through its treatment and processing platform, out to 17 injection platforms and down 62 individual wells to the formation below.

Dating back over 100 years, the waterflood concept is a popular form of reservoir management. The injected water helps to push the oil in the formation towards the production wells. While the concept is simple, there are a number of challenges to the actual application of a waterflood. A waterflood is one secondary recovery method used to ensure production in the later life of a field and make sure the field is effectively depleted.

There are a number of injection methods used worldwide; gas is a popular choice, as is steam. Seawater flood, the choice CABGOC made at Takula, is an inexpensive option, because the water is plentiful. The challenge is to design a program that makes the most of the injection capabilities and ensures the injection water does not plug or sour the reservoir.

Greater Takula

Greater Takula area is made up of five primary reservoirs; Banzala, the most recent, N'Sano, Numbi, Takula, and Wamba. Banzala, which is less than six months into production, is the only field in this complex that does not require waterflood. Electrical submersible pumps are used to draw oil from the reservoir. The Greater Takula area was first produced in the early 1980s; the initial recovery estimates were 27%, according to Chevron Petroleum Engineer Bob Mann. Water flood plans were initiated in the late 1980s in an effort to drive this recovery estimate up to more than 50%. To date, the WIP has pumped more than 1.1 billion bbl of water into the reservoir of these fields, plus additional bbl into the nearby Kungulo field.

Ron Kelly, Takula Complex Supervisor for Chevron said he is pleased with the job Nalco/Exxon Energy Chemicals, L.P. has done with this waterflood program. The filtration and chemical treatment of the seawater going into the formation has avoided many of the common complaints of waterflood projects. Poorly maintained waterfloods can turn sweet reservoirs sour," he said.

Patrick Neal is the Water Treatment Product Manager for Nalco/Exxon. Nalco/Exxon oversees the processing of the seawater injected into the reservoir. He said Chevron's success in avoiding the common pitfalls of waterflood comes as much from the company's attitude about the program at it does from Nalco/ Exxon's efforts. He said the most important thing Chevron has done is to consistently follow the prescribed treatment program regardless of market conditions. This has allowed a consistent quality of water to enter the formation and avoided scale and souring problems. Neal said in a low oil price scenario, the temptation exists to cut corners on injection water treatment. These decisions would not have an immediate effect on recovery rates or the quality of production. The problems would turn up down the line as a cumulative effect. The fact that Takula has successfully avoided scale and souring problems for 10 years illustrates Chevron's committment in treating the injection water.

Injecting 490,000 b/d of seawater into these fields and an additional 90,000 b/d into Kungulo has the effect of producing about 245,000 b/d of oil. Chevron reports recovery costs are in the neighborhood of $3/bbl, thanks in part to the uniformity of the formation. Ed Syed, Senior Petroleum Engineer for Chevron at Malongo, said Takula is being produced from an upper Vermelha zone of the reservoir. The field first came on line in 1982 with a well pressure of 1,300 psi. Primary production peaked in 1987 at 80,000 b/d and then declined to 800 b/d by 1990. He said it was clear early on that some sort of injection program was needed to increase the reservoir energy. The WIP was initiated in 1991. Production quickly increased to 45,000 b/d and peaked in April of 1995 at 130,000 b/d. In 1997, production dropped to 91,000 b/d, but with additional injection wells brought on line, production has been increased to 105,000 b/d.

Syed said the field has at least another 10 years of secondary recovery. His job is to identify those areas where there has not yet been WIP sweep. Syed looks for trapped oil ahead of the flood line and recommends wells to be drilled in these traps. Drilling and injecting into these areas, following a reservoir model developed over the 15-year life of the field, allows for close reservoir management and consistent production rates. While the waterflood of the Vermelha reservoir has been very successful, Syed said there are no further plans for additional injection wells in this zone. Future WIP plans are focused on the Upper Vermelha Messa Zone, another of the six reservoirs in the Takula field.

The water injection project in the greater Takula Area is primarily a peripheral flood. The formation itself is in the shape of a hill, according to Mann. This formation has the producing wells at the up-dip portion of the formation and the 62 injection wells scattered in a pattern around the perimeter. As the 490,000 b/d of water "sweep" through the formation, they effectively carry the oil to the wells, which are drawing it out of the reservoir. Because the water puts pressure on the oil as it sweeps, the gas contained in the oil stays in solution, keeping the oil lighter and easier to handle and reducing the amount of free gas in the reservoir.

There is no domestic market for the gas produced from the Takula field. Much of this gas is simply flared, while some of it is transported downhole and used for artificial lift in producing wellbores. When the gas mixes with the oil, it reduces the oil's gravity making it easier to lift to the surface. When one considers that the field is currently at 80% water cut, the need for artificial lift is understandable.

Waterflood is not a panacea for depleting fields. In 1987, when the Takula field began to loose pressure, the decision to waterflood was based on a variety of factors, not the least of which is that the field is a sandstone formation. Mann said sandstone is a very porous rock with high permeability. It is consistent and thus easier to map than most other strata. Carbonated reservoirs, by contrast, are not very porous; they often have a number of fractures and low permeability. This makes for a difficult waterflood, because the water is going to travel in the direction of least resistance. Features such as a fracture or variations in permeability can cause the water to drive in one direction, while failing to properly sweep the intended field.

Major threats

This diagram illustrates the water injection program for Takula.

While it is a readily available source of flood medium, seawater is literally teaming with life. Offshore West Africa is alive with plankton. The rivers that feed into the water near the Takula facilities carry silt, biomass, and minerals with them into the sea. The various solids in this water can be costly to remove, but even more costly to allow into the formation.

Among the major characteristics of seawater that pose a threat to the permeability of the formation is oxygen. The presence of high volumes of oxygen in the seawater contributes to corrosion in the flowlines. Oxygen feeds bacteria, which can reproduce in the flowlines and, in turn, develop biofilms.

This film builds up on the wall of tubulars and protects the bacteria that cause additional corrosion of the metal. This corrosion is such a threat that fiberglass piping, not susceptible to corrosion, is used throughout the preliminary stages of filtration where such bacteria may be present. Only when the water reaches the booster pumps is the fiberglass replaced with carbon steel. Carbon steel is needed to handle the high pressures produced by these pumps.

Marine organisms, also found in seawater, can cause fowling and plugging problems downhole. Basically, anything that is larger than the pores on the rock of the formation can cause plugging, Neal said. Larger organisms can also block flow through the various filtration units of the WIP. Suspended solids are another potential fouling and plugging source. Water that is muddy from river runoff may contain solids not easily broken down by acids. Rather than breaking them down, the program must filter these solids out.

The water injected into the formation can react with the natural formation water to create crystals called scale. These are particularly dangerous near the wellbore because they reduce permeability and require more pressure from the injection source. This also can affect the sweep of the waterflood.

To avoid this problem, Nalco/Exxon treats the first million bbl of water pumped into the formation with scale inhibitors. This creates a barrier between the natural water and the injected water to avoid scale formation.

Both aerobic and anaerobic bacteria pose a variety of problems for a water injection program. In addition to plugging the "pores" of the formation, these organisms can develop biofilm that leads to corrosion. While the bacteria cannot exist in the presence of chlorine, the chlorine has a limited effect on the biofilms. The chlorine can attack the surface of the film, but has poor penetrating power. Thus, it cannot reach the corrosion hotspots below the surface.

Even after the bacteria in the biofilms are killed, the detached biomass can pose a separate threat to porosity in the formation. The biofilms are best removed by pigging and back flow of seawater, which is then discharged over the side. In this way, the biofilm can be removed without posing a threat downstream.

Sulfate reduction

The anaerobic bacteria that threaten pro duction are also called sulfate-reducing bacteria (SRB). These bacteria are not only destructive in that they can corrode the metal and can plug the pores of the formation, but they also produce hydrogen sulfide. If hydrogen sulfide is introduced into the formation in high enough concentrations, it can actually sour the oil, requiring an extra step in refining. In testing for SRBs, several levels of concentration are examined to interpret the accumulation of the organisms.

Vials of seawater are taken from different stages in the filtration process. One vial will be tested at 100% concentration, while another will be tested at 10%, and another at 1%. The goal is to establish exactly how high the concentration of bacteria has become, so the seawater can be properly treated. The testing at different stages of the filtration process is also a useful tool in determining where the biofilms have developed.

Bacteria in the water are effectively killed by the chlorine introduced at the course filters. The dead bacteria are then removed in the bed filters. A large number of bacteria are more difficult to reach since they are present in biofilm attached to surface in the water, out of the reach of chlorine. These must be attacked by other biocides.

Other forms of discouraging the development of biofilms are high pressure and high velocity pumping of the water. It is known that the slime formers that create these films favor stagnant conditions. The higher the velocity of the fluid, the less likely the biofilms are to form.

Turning water to gold

The Takula WIP begins at a water depth of 65 ft where 10 lift pumps, working in a rotation of eight at a time, carry the raw seawater up to four course strainers. At the source, this water is initially treated with chlorine, produced via the hypochlorite generator located at the Takula facility. The chlorine treatment is designed to kill bacteria and other marine life in the water layer.

Although chlorine is a good biocide for planktol bacteria in the water. It is not as effective in environments where is must penetrate and kill the sessile bacteria present in a biofilm on a surface.

The course strainers remove large solids and biomater from the water. This includes everything from fish to particles no bigger than 80 microns. At this stage, the water is also treated with a biocide to attack the sessile bacteria to prevent biofilm from forming.

Once the water has passed through the course strainers, it has a particle concentration of less than 120/ml and total suspended solids (TSS) of less than 0.3 mg/liter. From here, the seawater enters one of 10 bed filters that use mixed media to further reduce the solids present.

To assist in the collection of solids, Nalco Exxon uses a filter aid in the water before it reaches the filters. This product is designed to bring a number of small particles together into larger clumps that are easier for the filters to catch. Water exiting the bed filters has a particle concentration of about 80 p/ml and a TSS of .05 mg/liter.

Because most of the solids in the seawater are collected in the bed filters, it is necessary to backflush these filters every 60 hours. This process involves pressuring up the filters then backwashing them with water. This process cleans the captured solids out of the filters.

For those solids not eliminated by the high-pressure backwash, a surfactant is introduced during every third back flush. This effectively keeps the filters clean and circulating. The water used in this process is discharged off the deck so it does not move downstream in the filtration process and cause further damage.

To cut down on the corrosion in the system, much of the oxygen is removed from the water before it is injected into the formation. This is accomplished using mechanical and chemical treatments. In the deaerators, the majority of the oxygen in the seawater is removed through a process of counterflow gas stripping. Gases are forced through the seawater and, in the process, free oxygen molecules from solution. The water is also run through six stages of garnet solids.

These tiny, gravel-like solids are kept separated by screens so that the water, which enters the deaerators at the top, passes through the largest of the solids and exits at the bottom, passing through the smallest. Because the water is moved very quickly through this filtration process, it has a tendency to foam. This can cause problems for the system's booster pumps. An antifoaming agent, added to the water as it enters the deaerators eliminates this problem. Although only one gallon of this antifoaming treatment is needed to treat the half-million bbl of water processed each day, it is a critical ingredient in the process.

At the tail end of the deaerators, the oxygen in the water has been reduced to about 40 ppb, which is not much, but is in excess of the 10 ppb required for the system. To drop the extra oxygen, it is necessary to add a chemical called an oxygen scavenger, which can reduce the oxygen content further.

One problem with reducing the oxygen content in the water to this level is that the chlorine used to control the bacteria will no longer be active. The oxygen scavenger also reacts with and deactivates the chlorine present in the system. To resolve this, biocide is introduced into the flow to ensure no biomatter is allowed into the formation.