Innovative technology key to field economics

Eldon R. Ball

Managing Editor

Development of the ConocoPhillips Belanak field offshore Indone-sia will combine a range of production structures, including two drilling platforms, an FPSO, a floating storage and offloading (FSO) vessel, and a variety of subsea connections. The field, con-sidered non-commercial on its discovery more than 20 years ago, owes its success to advances in technology and the cooperation of multinational oil companies and construction contractors.

ConocoPhillips, as operator, contracted with Halliburton affiliates PT Brown & Root Indonesia Ltd. (PTBRI) and Dresser Kellogg Energy Services (DKES) to design, engineer, procure, construct, and install the FPSO, moorings, and flexible risers.

Initial hull design and engineering were performed in Leatherhead, UK, while topsides design and project procurement were conducted from Singapore. Dalian New Ship Heavy Industry Co. Ltd. (DNS) shipyard in Dalian, China, completed the hull, marine electrical module, and living quarters in August. PT McDermott Indonesia Ltd. (PTMI) is building the topsides at its Batam, Indonesia, shipyard and will install them on the completed hull. Migas, PT Indospec, and the American Bureau of Shipping are certifying the facilities. The project is managed from Singapore.

The Belanak oil and gas field is located in the Indonesian sector of the Natuna Sea northwest of Kalimantan. It lies in 300 ft of water in the eastern portion of ConocoPhillips' block B concession area, and it contains mainly wet gas. When the Belanak field was discovered, its remote location and limits of the available technology made development economically impractical.

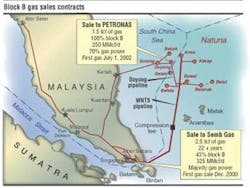

In January 1999, the Indonesian state oil and gas company, on behalf of the Republic of Indonesia, signed a gas sales agreement with SembCorp Gas (SembGas) of Singapore for the delivery of 2.5 tcf of gas over 22 years, with first deliveries beginning in 2001. The gas is supplied from three production sharing contracts (PSCs) in the West Natuna Sea, including the South Natuna Sea Block B PSC (operated by ConocoPhillips Indonesia Inc. Ltd.), the Kakap PSC (operated by ConocoPhillips Kakap Ltd.), and the block A PSC (operated by Premier Oil Natuna Sea BV).

null

These gas reserves are connected to the Singapore gas market via the ConocoPhillips-operated West Natuna Transportation System, a 656-km, 28-in. pipeline and gathering grid in the West Natuna Sea.

To meet the supply obligations under the SembGas and Petronas sales agreements and to develop and produce extensive oil reserves, ConocoPhillips and its South Natuna Sea block B partners, in partnership with Inpex Natuna Ltd. and Texaco South Natuna Sea Inc., began developing several South Natuna Sea fields. The cornerstone of this effort is the Belanak field project.

Field development

Development of Belanak started in October 2000, and sales to Malaysia began on schedule in August 2002, with the gas coming from dry gas fields in the western area of block B. Block B partners include ConocoPhillips Indonesia Inc. Ltd. (operator with 40% share), Inpex Natuna Ltd. (35%), and Texaco South Natuna Sea Inc. (25%).

The Belanak structure consists of two fields: Belanak and Southwest Belanak. The fields cover an area 16 km long and 4 km wide. Seven exploration wells have been drilled to date, showing five main reservoirs:

- Arang – a series of dry gas sands at 6,000 ft depth

- Gabus Massive – a thin oil rim overlain by a large gas cap at 8,000 ft depth

- Gabus Zone 3 – a series of oil sands overlain by a large gas cap at 8,500 ft depth

- Lower Gabus – a thick oil sand overlying a water contact at 9,000 ft depth

- SB90 – a series of thin gas condensate rich sands at 9,200 ft.

ConocoPhillips plans to develop the field by drilling 34 production wells from two wellhead platforms. The Gabus Massive reservoir will be developed with long horizontal wells, while the other reservoirs will be developed using conventional deviated wells. The Gabus Massive completion designs require downhole sand control (sand exclusion liners). The wells in the other reservoirs simply require oriented perforating. The dry gas reserves in the Arang reservoir will be developed later.

Belanak has proved hydrocarbon reserves equivalent to 142 MMboe. Gas reserves are estimated at 398 MMcf and oil reserves at 33 MMbbl. Production is scheduled to start in November 2004. Gas will be transported to Malaysia via a 96-km, 18-in. pipeline from block B to the Duyong complex offshore Malaysia for further transport by Petronas to mainland Malaysia.

The development facilities will include:

- Two fixed wellhead platforms and an oil offloading buoy

- An FPSO vessel

- An LPG-FSO vessel.

.

The two 24-slot wellhead platforms, with associated pipelines and an oil-offloading buoy, will support depletion of the two Belanak fields. The platforms are fully automated, remotely operated, normally unmanned facilities that are monitored by personnel located on the FPSO.

The top deck of each platform is sized to support a full platform-based drilling rig capable of drilling to 25,000 ft, with support equipment including three mud systems and accommodation for about 110 workers during the drilling phase. Drilling from the platforms will begin in October using a Nabors self-erecting platform rig.

The facilities will be linked by subsea pipelines, pipeline end manifolds, risers, and power cables, and tied into the existing block B gas pipeline infrastructure.

null

FPSO complexity

The Belanak FPSO is intended as the central oil and gas processing hub for the block B eastern area. The FPSO is one of the most complex vessels of its type in existence and is the world's first FPSO-based LPG plant. It has the capacity to handle production from other nearby fields, such as Kerisi, Hui, and Belut, which are all in different stages of development.

Hydrocarbons will be produced from wells drilled on wellhead platforms A and B. Crude oil will be processed on the FPSO and exported via the loading buoy. Gas will be transported through the export line, while LPG will be offloaded from the nearby FSO.

The Belanak facilities will be capable of:

- Producing and processing oil, dry gas, and LPG

- Intermediate storage and exportation of stabilized crude oil

- Exporting pipeline-specification dry gas

- Intermediate segregated storage and export of LPG products (propane and butane).

Process and export capacities are:

- 100,000 b/d of oil

- 28,000 b/d of recovered LPG, including condensate

- 420 MMcf/d of sales gas

- Gas injection capacity of 200 MMcf/d

The LPG-FSO will be turret-moored 2.2 km southeast of the FPSO. The mooring will enable the vessel to weathervane freely. LPG will be received from the FPSO through two rigid export pipelines, connecting the PLEM at the FPSO with a PLEM beneath the LPG-FSO. Two flexible risers will connect the PLEM to the swivel turret mounted on the bow of the LPG-FSO.

The LPG-FSO vessel will be able to store 78,000 cu m of LPG. The LPG, in refrigerated or pressurized form, will offload to trading LPG carriers. During offloading, the tankers will be moored alongside the LPG-FSO.

Contract negotiations for the LPG-FSO are in progress. The vessel may be either a conversion or a new-build.

Technological challenges

The size and complexity of the topsides and the inherent difficulties of installing an LPG plant on a floating structure challenged both the topsides and marine designers. The Belanak FPSO is the most complex ConocoPhillips has installed offshore, and the safety, environmental, and process engineering considerations for the unit are considered to be at the leading edge of the offshore industry's knowledge and experience.

The FPSO will have a topsides operating weight of nearly 31,000 tons, with the following design features:

- Processing capacity of 100,000 b/d of oil or total fluids, with up to 50,000 b/d of produced water

- Storage of 1 MMbbl of oil and condensate

- Offloading capacity of 25,000 bbl/hr of oil or condensate to a shuttle tanker via the offloading buoy

- Low-pressure gas compression of 360 MMcf/d through two 11,000-hp electrically driven compressors

- Treatment of 377 MMcf/d of sour gas to remove hydrogen sulfide

- Dehydration of 522 MMcf/d of gas

- Export of 24,000 b/d of propane and butane

- Export of up to 420 MMcf/d of sales-quality gas through two Rolls Royce RB211-driven export compressors

- Re-injection of 200 MMcf/d of gas through a 14,000-hp electrically driven compressor

- Generation of 50 MW of continuous electrical power using five Rolls Royce Avon-driven generator sets

- 30-year design life, with no requirement for interim dry-docking.

Marine considerations

Unique challenges faced the marine design and engineering teams, including:

- The 30-year service life

- The large topsides loads (31,000 tons) that impacted stability

- The need for stringent motions restrictions, to ensure that the LPG pro-cessing facilities onboard could operate efficiently.

The hull has been designed and built as a double side, single bottom configuration with no self-propulsion. It includes 14 oil/condensate cargo tanks providing 1 MMbbl of storage, 18 ballast tanks (14 wing tanks and four fore and aft peak tanks), and two slop tanks.

The FPSO contains 14 cargo pumps: one located in each tank delivering 1,000 cu m/hr, with three booster shipping pumps (2,000 cu m/hr) located on deck. Four pumps handle ballast through at 1,400 cu m/hr into a 14-in. ring main at tank bottoms.

Mooring and motions

Weather conditions in the Natuna Sea favor a spread-moored system of anchoring, with no turret required. The FPSO will be moored with aft facing the prevailing northeasterly winds, and it will be anchored by 14 mooring lines requiring over 11,000 m of 127-mm-thick steel chain anchored into the seabed by 14 suction piles.

This system has been shown to have a fatigue life of over 300 years and is designed to withstand a 100-year storm without exceeding the flexible riser watch circle.

Two riser porches are located forward and amidships on the starboard side. These will support nine flexible risers – two production, two oil offloading, two LPG export, two wellhead platform gas injection, and one gas export riser. Three 13.8-kv subsea power cables exit the FPSO from the riser porches.

The mooring system is designed to ensure that the motion of the operating vessel is adequately stable for reliable LPG production. The allowable movement at the top of the LPG fractionation columns, some of which are over 60 m high, is +/- 2° from vertical (roll or pitch, including static tilt). The current design demonstrates less than 1.75° more than 99% of the time.

The hull was designed and built to last 30 years without the need for dry-docking.

Belanak FPSO marked major milestone for China yard

The contract to build the hull, marine electrical equipment module, and the 120-person living quarters with Dalian New Ship Heavy Industry Co. Ltd. (DNS) of Dalian, China, marked the first time that ConocoPhillips and Kellogg Brown & Root (KBR) had built an FPSO hull in China. Likewise, DNS had not previously built an FPSO of such size and to such exacting specifications.

DNS was established in August 2000 when it was separated from the original Dalian Shipyard within which it had operated for 40 years. The Chinese government, through the China State Shipbuilding Corp., has invested heavily in DNS, which now has a capacity of 200,000 dwt per year. DNS has delivered over 60 vessels, including semisubmersible rigs, jackups, and two previous FPSOs. This track record plus an order book for 14 newbuilds, including five 300,000-dwt very large crude carriers, helped show that DNS could meet the demands for competitive price, quality, and the exacting delivery schedule expected by the Belanak FPSO project team based in Singapore.

ConocoPhillips and Dresser Kellogg Energy Services (DKES) say they worked as a team with DNS throughout the construction period. Communication between DNS and the DKES site team in Dalian, as well as the design teams in Leatherhead, UK, and Singapore was seen as a challenge. To help facilitate communication, the project leadership integrated teams with Mandarin-speaking members in key positions. To DKES and ConocoPhillips, the success of the teamwork was demonstrated in the delivery of the completed hull, marine electrical module, and living quarters in 18 months from first cutting of steel on March 15, 2002, and 24 months from the beginning of design.

The ship was built using modern shipbuilding block assembly. The aft section, representing about 40% of the hull, was built on a slipway and then launched into the sea to be towed to the 375-m x 80-m drydock. In drydock, the fore section blocks were assembled and the whole hull joined together.

In parallel to the hull assembly, the 4,700-ton marine electrical module was constructed on the quayside along with the 1,220-ton, 120-person living quarters. Both modules were lifted onto the hull in drydock in March. The hull was launched from drydock on March 26 and was docked along the quayside for final fitting-out and commissioning of the marine systems.