Combining expandable sand screens with propped hydraulic fracturing technology

Brunei Shell Petroleum (BSP) and Halliburton Energy Services applied a combination of expandable sand screens (ESS) and hydraulic fracturing during the completion of two wells in the Egret field, Brunei. The result was effective sand control with completion flexibility and improved productivity. This technology combination was applied to three oil reservoirs that were completed and produced commingled, using one gas reservoir as a lift source resulting in a skin of less than +1.

Egret field

BSP’s Egret field is 43 km (27 miles) offshore in 60 m (197 ft) of water. The field consists of stacked sand formations (mainly gas and some oil-rim reservoirs), broken into multiple blocks by faults. The operator’s first production from three gas wells in November 2003 was transported via a 25-km (15.5-mi) multi-phase gas pipeline at 7 MPa (1,015 psi) back pressure to processing platform AMDP06.

To ensure that the well would flow against the back pressure, an artificial lift technique was needed in the completion configuration. The idea of using one of the gas reservoirs as a source for lift was investigated and found to be feasible.

Another technology considered was intelligent completion with real-time monitoring of pressure and temperature from any zone and control of production, either individually or commingled, without well intervention. Permanently installed electric cables provide power and communication with the downhole sensors and valves. Each well contained two to three interval control valves (ICVs) and four downhole pressure gauges (DHPGs).

Technologies facilitated field development planning updates, developing an intelligent well field philosophy and also alternative methods for developing oil rims in complex conditions such as producing against a high-flowing tubing-head pressure. The team decided to include these technologies in the completions.

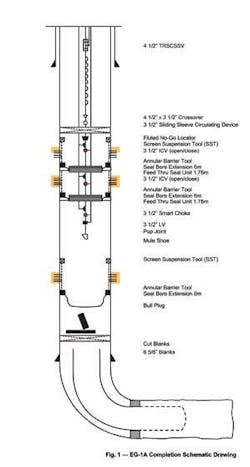

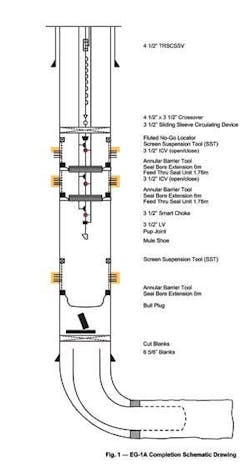

The first well, EG-1A, was a dual string producer lifted with gas from reservoir BP1. A single trip balanced perforation of three zones, followed by a stacked, propped-fracture operation prior to installing an expandable sand screen was planned. The second well, EG-1B, was planned for a similar completion except for separate perforation trips based on experience gained from EG-1A.

Challenges

The team decided sand control was needed. A sand screen and hydraulic fracturing were selected. An expandable screen was chosen because the increased inside diameter (ID) would help to optimize the completion design. These combined technologies were key to achieve the production performance. Screen plugging was minimized while sand production was effectively controlled with a low skin factor.

Another challenge was to optimize the well design in three months. During this time, a variety of new technology applications would have to be combined and pre-completion procedures reviewed with the well construction team. The completion operations would include single-trip perforation methods for three to four producing zones followed by stacked frac packing and expandable sand screen expansion before the intelligent well completion assemblies (3 ICVs, 1 variable ICV, 4 DHPGs) with three control lines could be run.

Other challenges in the pre-completion phase were to control lost circulation, to maintain a clean wellbore prior to running the expandable sand screen, and to place multiple fracture treatments.

Completion design

BSP’s initial field development plan (FDP) called for development of the gas reserves prior to beginning the oil development in 2007. However, following an appraisal well in 2003 that confirmed greater than expected oil reserves, the development was accelerated by three years, a project of $51.7 million net present value. In addition, the early production data gained from the oil rims would help to reduce the risk of further field development.

BSP spudded two oil wells, EG-1A and EG-1B, in October 2004. Seven producing zones were completed with hydraulic fracs and 250 m (820 ft) of expandable sand screens. The team installed and successfully expanded all screens.

The old FDP called for all Egret wells to be completed with sand control based on comparison to nearby fields, particularly the Fairley field 7 km (4 mi) west where sand control is required to a depth of some 2,750 m (9,022 ft) true vertical subsea.

The Egret field’s first gas production was from three wells in November 2003. Traditional sand control methods using the micropolymer gel were applied in these wells; two wells have a standard acid pre-pack IGP, and one well is a 400 m (1,312 ft) horizontal open hole with a gravel-pack completion. BSP’s initial production was below expectation, and after a year, the skin was more than +20. Fines plugging was the suspected primary cause since the formation grain size has more than 15% fines content on average. The team re-evaluated sand control methods to improved productivity leading to fracture stimulation to increase the effective wellbore diameter and to reduce fines flow velocities into the well.

The team’s requirement of the larger ID to accommodate a total of three control lines, two ICVs, one HCV, and four DHPGs suggested the use of an ESS expanded in the 9 5/8-in. (244 mm) perforated casing. The decision to include propped hydraulic frac as part of the completion came late in the well planning process when the existing wells showed low productivity plus a risk of hot spotting in the expandable sand screen.

The completion philosophy, therefore, called for the amalgamation of three technologies in the same well, namely intelligent well completions, expandable sand screens, and hydraulic fracturing.

Stimulation and screen installation

Although both EG-1A and EG-1B were completed with similar philosophies and design, they were dissimilar in terms of installation. As EG-1A was the first to be completed, and lessons learned were applied on EG-1B.

Halliburton’s propped fracture stimulation was designed with 500 to 800 lbm/ft using 30# borate cross-linked carrier fluid. EG-1A was designed with a maximum of 12 lbm/gal sand concentration whereas EG-1B was designed with a maximum 14 lbm/gal sand concentration to maximize fracture conductivity.

Upon completion of the lowest zone of EG-1A with approximately 500 m (1,640 ft) of wire-wrapped screens in the horizontal section, the zone was isolated with a bridge plug, and the upper three zones were perforated in one run. However, the lowest perforation assemblies parted and were left in hole.

What worked, what didn’t

Due to the limited availability of case histories and successful combining of the three technologies; the completion of the two wells resulted in a steep learning curve. The specific challenges were:

- Fluid-loss control

- Effectively isolating zones that had been treated while achieving a balance between operational risk and rig-time optimization

- Wellbore cleanup

- Successful screen expansion.

The teams’ choice of fluid loss control was to ensure safe, efficient operations in addition to minimizing formation damage. During EG-1A operations, a hyroxyethyl cellulose polymer gel (HEC) with internal breakers was used as the primary lost-circulation material (LCM), because particulate LCM such as graded salt could plug the ESS expansion tool.

The experience on EG-1A and EG-1B showed that the use of a retrievable bridge plug to isolate zones that have been treated may add complexity and risk to the overall operations. In wells with a low angle of deviation, sand plugs may be the most appropriate method of isolation with minimal operational risk, in addition to being cost effective.

BSP’s wellbore cleanup was critical to ensure trouble-free installation of the ESS assembly. On EG-1A, the screen suspension tool prematurely set due to debris and proppant from the zones above. However, subsequent jobs on the top installation and EG-1B were trouble free owing to the additional cleanup trips and to the change in the perforating process.

Lessons learned

The combination of ESS with hydraulic fracture stimulation and intelligent well completion helped accelerate production of the oil, as of January 2006, at a sustained rate of 1.5 Mcm/d (9.4 Mb/d) which supported BSP’s production target for 2005 and proved incremental oil reserves. Acquisition of real-time reservoir data from the intelligent completion will be used to optimize future development.

The concept of gas (for gas-lift)/oil dual production used for these wells was the key technology to produce the small oil rims economically.

Editor’s Note: This is a summary of SPE 101187 presented at the 2006 SPE Asia-Pacific Oil & Gas Conference and Exhibition held in Adelaide, Australia, Sept. 11-13, 2006.

Sakamrin Abdul

Rahman Ceng MEI

Brunei Shell Petroleum

Derek Lim

Jit Juan Lim

Kuo Chuan Ong

Halliburton Energy Services