DRILLING TECHNOLOGY: As US training becomes responsibility of operators, computers take up function

The US Minerals Management Service (MMS) of the US Department of Interior, will no longer accredit schools or other organizations for well control and production safety training and certi-fication according to upcoming guidelines. On October 15, 2002, the new MMS-amended Federal Register (30 CFR part 250, subpart O) regulations take effect, allowing the use of computerized interactive multimedia-based system for well control and production safety systems training.

Lessees (producers and operators) will be held accountable for competency and skill assessment of employees and contractors. This program satisfies the requirements mandated by the new federal regulations to develop a training plan, verify competency and frequency of oilfield training, and document and maintain records for both operator personnel and its contractors.

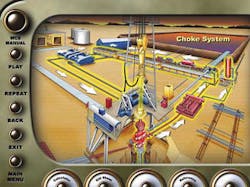

A training program, System 21 well control and production safety systems training, was developed by Well Control School (RPC) to meet the new guidelines set by MMS subpart O training regulations. The program contains self-paced training and can be implemented at the rig site or platform, at an office, in-house school, or at other established permanent locations.

The program can reduce overall training costs as much as 50%, by eliminating expenses for travel, hotel, meals, overtime, and relief personnel. Over 2,000 topics and skills offering training, testing, simulation, and employee competence are covered. Inter-active tasks and role-playing familiarize learners with well control concepts, emphasizing correct procedure and teamwork.

Aids in learning

Computer graphics depict downhole conditions such as deepwater or horizontal drilling. After each module is completed, a skill level is recorded and progress reports are generated as the users work toward obtaining certification in drilling, well completion, workover, well servicing (snubbing, coiled tubing, wireline), and subsea.

Specifically, the production safety systems training (PSST) is a self-contained interactive and simulation program providing required T-2 Training certification. After a three-year development schedule, the MMS allowed the use of this computerized interactive multimedia-based system for offshore safety systems training.

The portability of the system means training may take place anywhere, at any hour, reducing travel cost and the use of contract instructors. Under-utilized discretionary time becomes productive time. A database maintains records and tracks each individual's progress. Random testing and security ensure that each student completes his training. MMS reports can be generated, and certificates and wallet cards for individuals may be printed upon completion. The average individual completes the course in 15 hours.

Course components include: Maintenance, Installation and Repair of Safety Systems, Level Safety High/Low, Pressure Safety High/Low, Pressure Safety Valves, Well Control Panel I and II, Safety Analysis and System Design, Regulatory Material, Smoke, Thermal, UV and Gas Detection, MMS Certication Testing and Student and Training Administrator Guides.

MMS audit

The MMS or an authorized representative can conduct an in-office training system audit, thus firms must be prepared to explain their training program and produce evidence to support explanations.

Procedures must be developed to verify that all employees and contract personnel can perform their assigned duties plus ensure that the contractors' training programs provide for periodic training and verification of well control or production safety knowledge and skill assessment.

Each company must establish and implement a training program verifying that all of their personnel are trained to competently perform their assigned well control and production safety duties.

Course content and reports will also help companies conform to the standards set forth by ISO 9000 addressing training, record-keeping, and quality audits. This also can be a valuable tool for companies to use to qualify and maintain ISO certification. This course lays out a suggestion for "internal audits" and how audits will verify that an effective system is in place.

- ISO 4.16 control of quality records: Quality records shall be maintained to demonstrate conformance to specified requirements and the effective operation of the quality system. Records may be in the form of any type of media, such as hard copy or electronic media (This supports MMS 250.1503 - 5 & 6 (c)1 and 2).

- ISO 4.17 internal quality audits: Internal quality audits shall be scheduled on the basis of the status and importance of the activity to be audited and shall be carried out by personnel independent of those having direct responsibility for the activity being audited (This supports MMS 250.1507a).

- ISO 4.18 training: The supplier shall establish and maintain documented procedures for identifying training needs and provide for the training of all personnel performing activities affecting quality. Personnel performing specific assigned tasks shall be qualified on the basis of appropriate education, training and/or experience, as required. Appropriate records of the training shall be maintained (This supports MMS 250.1503 - 250.1506).

Benefits of the system are as follows:

- Verify competency: Upon completion of either well control or production safety systems training, a report is issued. This includes the certification test score, topics and skills covered, as well as custom reporting on those areas where individuals missed questions or had to make repeated attempts on a simulator. This extensive reporting system provides proof of competency and verifies that more than 2000 topics and skills have been administered and assessed.

- Comprehension of key points: Ensures comprehension of key points, preventing an individual from moving on until the material is completely understood.

- Pre-tested, post-testing: Individuals are pre-tested and post-tested on all modules, plus given a certification test. If an individual misses a question, they return to the appropriate section for instruction and are then re-asked the question. Random test questions for every module are administered to validate competency in each area covered.

- Electronic record-keeping: Allows one to provide full disclosure of an individual's performance at the touch of a button.

As the deadline for compliance of the new MMS subpart O regulations approaches, one thing is certain - companies must comply. These MMS subpart O regulations clearly identify and make defined mandates of what must be implemented concerning training, record-keeping, and training plan audits. MMS wants to know that the employees and contractors can pass the written test, and can also perform the necessary skills to get the job done properly and safely.