Rich Granger

Michael Neal

Battelle

Richard Pomerleau

Harald Grob

OceanWorks International

Offshore oil and gas operations present a challenging environment. Operators incur substantial costs to maintain assets and verify compliance with regulations, and environmentally induced delays of infrastructure inspections cause loss of production revenue. In addition, inspection and monitoring of deepwater hardware is human and equipment intensive and increased operations strain resources.

As autonomous underwater vehicle (AUV) operations increase in scale and complexity, the need for subsea persistence increases. Implementation of this resident AUV system will provide benefits for oil and gas operators and service companies in areas such as environmental baseline data, increased efficiency, improved safety, and reduced cost. The combination of Battelle and OceanWorks technologies to develop resident AUV interface infrastructure would make possible remote inspection and intervention without the need for surface support or complex umbilical handling systems.

Many of the challenges associated with offshore oil and gas operations, especially in deepwater, can be addressed by deploying subsea inspection and monitoring systems with increased persistence. The benefits of persistence include:

- The ability to conduct cost-effective long-term environmental monitoring to establish and track conditions before exploration, during exploration, and after exploration on through production

- The ability to conduct frequent, cost-effective inspections for pipeline and equipment integrity

- The ability to respond quickly to out-of-cycle inspection requirements

- The ability to tie-in with seafloor network instruments.

Battelle and OceanWorks International have demonstrated technologies to enable persistent AUV operations from a seafloor node network that incorporates a subsea docking, recharging, and communications.

Such a system would enable resident AUV presence on the seafloor, providing cost-effective support for a variety of oil and gas exploration and production activities.

Operators use AUVs for a variety of tasks, including bottom surveys, pipeline tracking and inspection, and infrastructure inspection. Current AUVs are supported from surface vessels. The equipment must be physically recovered aboard the ship to replenish batteries and download data. This means that the ship must remain on station while the AUV is working, and that safe AUV operations depend upon favorable weather and sea conditions.

In oil fields with assets spread over tens or even hundreds of square miles, a docking and recharging station would allow a vehicle to deploy from a central site, transit to an inspection area, perform the inspection, then return to the docking station to recharge batteries and offload inspection data. Once recharged, the vehicle would move to the next inspection area to repeat the operation. This would alleviate the need for a ship to tend the AUV while it works and would reduce potential for vehicle damage or loss during launch and recovery.

The persistence given by the AUV's independence from the surface enhances its efficiency in routine operations. In addition, a persistent, docking station-based AUV could deploy for out-of-cycle (e.g., post-hurricane) inspections more rapidly than transit-time-limited, surface-based system, reduce time required to complete inspections, and resume production faster after a natural event.

Recent developments, such as the 2011 demonstration of an AUV docking and recharging station in Boston Harbor performed by Battelle and Bluefin Robotics, coupled with existing Seafloor Network infrastructures, such as the VENUS, NEPTUNE, and CSnet OCB subsea nodes, primarily developed and built by OceanWorks International, have established baseline capabilities to deploy a persistent seafloor-based AUV.

AUV docking station

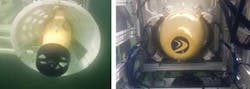

In late 2011, an undersea system demonstration in Boston Harbor culminated several years of work by Battelle and Bluefin Robotics on an AUV docking and recharging station – the undersea equivalent of a filling station, where an AUV could "gas up" and "phone home." The system successfully demonstrated autonomous homing, docking, recharging, data exchange, and re-launch.

Work on the AUV docking and recharging station began in 2007 as an internally funded effort. A number of concepts were examined. The submarine-mounted version was the primary focus and came to fruition through sponsorship from the Office of Naval Research, and later supplemented by the Commander, Submarine Force.

In these programs, Bluefin outfitted one of its 12.75-in. diameter AUVs with a device that enabled it to home in and then dock for data exchange and recharging. Once docked, the vehicle used a Wi-Fi connection to download data and upload its next mission profile. Inductive coils on the vehicle and dock transferred energy from the dock to the vehicle – an approach not unlike a counter-top charger for an electric toothbrush – without the need for metal-to-metal contacts.

Building on this successful at-sea demonstration, Battelle has launched an internally funded research and development project to demonstrate an enhanced undersea electrical energy transfer system. The new project aims to improve the efficiency of an inductive power transfer subsystem. This would, in turn, enable increased persistence, higher reliability, and faster turnaround time for AUVs and other subsea systems.

The 2011 demonstration yielded undersea power transfer efficiency of 74% with a charge time of 12 to 16 hours for a 12-in. AUV. The new OceanHub system will be 85% to 90% efficient, reducing AUV charging time to four to six hours. Initial proof-of-concept tests were completed in early 2014, with additional development and demonstration to follow. Although initial development will focus on AUV replenishment, the system architecture supports a wide variety of subsea power transfer applications.

Seafloor network infrastructure

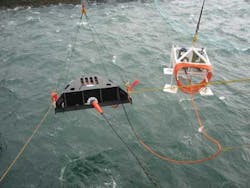

OceanWorks International has supplied hardware and software for seafloor network infrastructures, also known as cabled ocean observatories, since 2005. A seafloor network is a subsea infrastructure that can stretch for hundreds of kilometers along the ocean floor. Each network provides power and communications to arrays of distribution nodes on the seafloor. Starting with a single node structure 100 m (328 ft) deep, OceanWorks pioneered development of many modules to expand the capability of these systems, which now can monitor hundreds of instruments in real-time at depths to 3,000 m (9,840 ft), and even greater depths if required. Seafloor networks are built from modular blocks. Requirements differ for each application, and the seafloor network modules can be arranged in different topologies, with different features.

The modules are designed to operate for at least 20 years, providing a permanent infrastructure on the seafloor that supplies continuous power and high-speed data communications to instruments and equipment. Common seafloor network infrastructures are composed of four main modules: a shore station, a telecommunication cable, a primary node, and a subsea instrument interface module (SIIM) package.

The shore station is where the cable comes ashore. It includes an anode for sea water power return, a medium- or high-voltage power supply, and a high-speed Internet connection. The standard telecommunication cable, composed of a single power conductor and multiple optical fibers, can be laid or buried as required. The primary nodes connect to the telecommunication cable and convert power to an intermediate voltage. The nodes have underwater mateable connectors to distribute power and communications to secondary nodes, SIIM packages, or instruments. Finally, the SIIM connects to a node via an underwater mateable connector and provides a range of individually switched and monitored low-voltage ports and communication options to support a range of instruments.

Starting in 2005 OceanWorks acted as the system designer for the Victoria Experimental Network Under the Sea (VENUS) project to design and manufacture the shore station, primary nodes, and SIIMs.

The VENUS project consists of two separate cabled observatories: VENUS Saanich and VENUS Strait of Georgia (SoG). VENUS is the world's first multi-node cabled observatory. The three nodes and 12 SIIMs are deployed in water ranging from 100 to 350 m (328 to 1,148 ft) deep and extend as far as 40 km (25 mi). Up to 3 kW per node is available for distribution to SIIMs and instruments. Power converters, communications, and control in each node are dual-redundant to improve overall system reliability.

OceanWorks designed and built 14 SIIMs for the North-East Pacific Time-Series Underwater Networked Experiments (NEPTUNE) Canada project, which will meet growing scientific demands for the next 25 years. Each SIIM manages and distributes between 5 and 9 kW of power and can be placed up to 10 km (6.2 mi) away from a node at depths to 3,000 m (9,842 ft).

The Offshore Communications Backbone (OCB) is a seafloor network developed for the Mediterranean Sea off Cyprus. The greater OCB system is a fully flexible and re-deployable seafloor network that can supply up to 1,500 W per node for a variety of instruments. The system operates in depths of to 3,000 m and has more than 250 km (155 mi) of total cabled distance.

Most instrument ports on OceanWorks nodes and SIIMs have the following characteristics:

- Software adjustable 12 to 48 VDC @ 5A or fixed 24 VDC @ 5A. 375 VDC @ 5A

- Software selectable communication protocol EIA-232/485/422 serial and/or 10/100BaseT Ethernet.

OceanWorks has developed battery pods and uninterruptible power supplies (UPS) rated to 3,000 m or greater if required. The UPS is based on a standard 150 kWhr element, which can standalone or connect in a daisy-chain or hub configuration to store up to 1 MWhr of energy. The UPS system allows for load levelling of high power operations on a duty cycle to limit peak current on the seafloor network (e.g., while recharging an AUV in a docking station) and to provide secure autonomous backup power and control for critical systems and controlled shutdown of sensitive equipment in the event of a network power outage. The UPS system can also be used as centralized power for short deployment subsea systems.

System concept and path forward

The envisioned resident AUV system will integrate a commercial OceanHub variant of the Battelle/Bluefin AUV docking and recharging station with OceanWorks seafloor network infrastructure nodes. Features will ensure forward compatibility with other subsea infrastructure. The baseline version of the system will use a standard Bluefin-12 or -21 AUV, with the option to accommodate different vehicles in future versions.

Implementation of this system will occur in phases, to demonstrate system performance under conditions of increasing depth and complexity.

During Phase 1, the system is planned to be demonstrated at the VENUS Saanich Inlet site, which is located 3 km (1.86 mi) from shore at a depth less than 100 m (328 ft). This phase will culminate with the Bluefin AUV performing an inspection on a mockup pipeline installed at the site. Phase 1 system engineering and site planning are in progress.

During Phase 2, engineering upgrades will be made to accommodate deepwater conditions. This phase will conclude with a system functional checkout prior to deepwater deployment. Phase 3 is planned to feature a deepwater demonstration of the resident AUV system at the NEPTUNE or CSnet OCB site (>2,000 m/6,560 ft depth).