Accessibility, connectivity critical for effective action

Murray Callander, Joel Chacon

Eigen

Wide-ranging safety models and controls have been implemented offshore since the Piper Alpha incident in the UK North Sea three decades ago; however, catastrophic tragedies still occur from time to time. Oil and gas companies need improved control over uncertainty to achieve their twin goals of improving productivity without jeopardizing safety.

The industry has developed numerous paradigms to assess and manage safety risks, the most recent and comprehensive being Safety Barrier management, pioneered as a regulation by Norway’s Petroleum Safety Authority. However, Safety Barrier management, which is an essential part of Operational Risk Management (ORM), is very complicated because the information needed is vast, complex and spread over multiple systems, documents and personnel. Most companies collate at least some of this information once a month into a report or static dashboard.

The Swiss cheese model. (Courtesy David Mack)

But it can become virtually impossible for industry leaders to validate or further question these summary and static reports. The organization can also bias the reports by playing the reporting periods to its advantage (i.e. delaying bad news until the 1st of the month, to give sufficient time to fix it before the next report).

The Swiss cheese model of accident causation highlights how different means and controls to prevent hazards fail in such a way that the hazard is allowed to propagate through the various ‘holes’ in the cheese slices, and that once this occurs, no further cheese slices exist to act as ‘barriers’ to prevent an accident and its subsequent consequences.

A Safety Barrier, by definition, is anything intentionally put in place to prevent undesirable situations, such as harm to people or loss of life, but which also includes damage to the environment and reputation, or financial loss. It does not have to take a physical form: it can be a protective system logic, an organizational control (similar to a permit), or even the culture within an office.

The Swiss cheese model encourages offshore installation managers to be aware of the different barriers, or slices, and the corrective actions needed to mitigate the risks of failure of each one of the slice’s holes, so that hopefully those holes never align (i.e. with successive failure of barriers), triggering an accident.

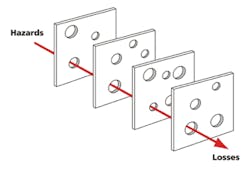

Example of barrier or protected areas. (Courtesy Eigen)

But for the industry to attain a higher level of safety, the following questions should be asked:

• What causes the ‘holes’ to appear in the Swiss cheese slice in the first place - why are the safety barriers impaired or ineffective?

• How long have they been in that condition, and is anybody doing anything about it?

• Is the manager responsible for the safety of operations aware of the relative importance of all the different Safety Barriers? And to what extent do controls that are impaired contribute to the overall risk?

• Where are the biggest risks – the see-through ‘holes’?

• And what are the consequences of a corresponding hazard event?

Safety Barriers are designed by competent process/instrument/control engineers. They are signed off by qualified client representatives and managers, and implemented and tested during commissioning – but the crucial question during the operation should be – are they working now? If a pressure sensor feeding various shutdown logic arrangements has been bypassed for maintenance, operatives need to know the incremental risk this poses to the barriers it supports – when it is due to be fixed and by whom. On increasingly complex offshore assets with hundreds of thousands of equipment tags and high-pressure operations, the task can be incredibly daunting – and this is where the concept of Barrier Management comes into play.

Many factors can affect the health status of a Safety Barrier. (Courtesy Eigen)

There are various challenges involved in ensuring adequate safety standards by assessing how to safeguard operations, facilities and human life on offshore operations:

• Managers need to know which barrier areas present the highest risk and which are the worst maintained. This requires a sufficiently flexible and configurable data model that can be used to extract appropriate insights. Being able to delve down and explain why a barrier is impaired enables corrective actions to be taken and builds general trust in the system.

• Barrier impairment can have many origins, one example being the Maintenance Work order system or the record of statutory equipment and instrument tests. In this case barrier impairment can be the result of pending Corrective Work orders or Preventive Work orders. A Corrective Work order usually means something is already broken, and the presence of an overdue Corrective Work order implies the impairment is worse than an overdue inspection. What is needed is a means of quantifying barrier element impairment severity that can in turn be used to determine cumulative risk against plant areas or major accident types. For a Safety Barrier Health Management System to be effective, it must also provide access to all available information in near-real-time.

The process safety overall work process. (Courtesy Eigen)

Managing barrier impairment

The various impairment severity measures to be adopted must conform to practical rules that enable segregation of risks in a wide range of categories for effective prioritization. How the severity of risk is apportioned and how it is aggregated differs from company to company, but it is essential that any Safety Barrier Management application allows users to undertake risk assessment and record the outcomes, and this outcome must modify the severity measures and statuses applied to the aggregation rules.

In an asset with multiple major accident hazards, visualization of risk and status is a significant challenge. Managers must have access to the ‘big picture’ and be able to ‘drill down’ to any level of detail required. Operators and other system users need to access the required information in a few clicks, and to be able to prioritize actions.

A practical and scalable way of visualizing all the Swiss cheese layers is essential. In a modern offshore facility there can be thousands of barrier paths from barrier element to hazard and to the corresponding further consequences. This information must be available in its entirety in a web browser and accessible through mobile devices. The best solutions make provisions for all these aspects while providing a top-down picture of the risk, enabling visualization of all barrier paths in one diagram, and all users to quickly and intuitively navigate, according to their needs.

Eigen Ingenuity Safety Barrier health module presents live barrier health from all perspectives. Each element is interactive. (Courtesy Eigen)

Conclusion

For effective Barrier Management, hazards and barriers, with their functions, elements and performance standards, must be organized in a single data model and adapted to the complexities of relationships that must be inferred - otherwise, navigation, drill-down and roll-up of information becomes impractical or too slow for a practical user experience.

Barrier impairment information originates in many disparate systems which are typically already in place. The system must be able to connect to these data sources in a modular and supportable way. Equipment tags and ICSS system tags need to be mapped to their corresponding barrier elements in the system, and the status must flow in near-real-time, with negligible impact on the source systems. Once the information is organized and the data is flowing, users will be able to explain and understand why each barrier is impaired, allowing corrective value-adding actions to be implemented in the right order, at the same time building staff trust in the system.

The system must also be sufficiently flexible to cope with criticality level thresholds and tagging issues such as being fixed or as ‘OK.’ Finally, it must be able to present the information in multiple web browsing platforms; employ novel visualization paradigms to present the information in summary form; filter according to different criteria; and enable intuitive drill-down to relevant details when required – in just a few clicks. •