Large-scale fiber-optic sensing enables life-of-field reservoir monitoring

Martin Bett - Stingray Geophysical Ltd.

The prize of enlightening the reservoir using large-scale, high-fidelity, fiber-optics to provide timely, predictive information on reservoir performance is within our grasp. Fiber-optics revolutionized the telecommunications industry, enabled the World Wide Web, and can do the same for the instrumented oil field.

Fiber-optic Seismic Permanent Reservoir Monitoring (Seismic PRM) has the reliability and resilience-to-failure required to make long-term reservoir management strategies a reality today, fed by frequently updated, high-fidelity seismic data. A planning method that borrows from the subsea engineering industry to implement feasibility and FEED studies as part of a professionally implemented Seismic PRM project will deliver successful projects and high quality data. This data, in turn, can be used to inform reservoir management strategies to increase production and increase reserves at lower overall costs and risk.

Reservoir heterogeneity continues to challenge the quest to optimize production and increase recoverable reserves. This challenge is encapsulated by the so-called “Three Laws of Reservoir Heterogeneity,” which state that:

- 1. All reservoirs are heterogeneous

- 2. All reservoirs are more heterogeneous than at first imagined

- 3. The degree of reservoir heterogeneity increases as the reservoir is produced.

The oil industry is unique in not being able to observe its production facilities or “factories” directly. And, although there is progress in creating an image of our “factory” and the extraction process, operators are informed sparsely about spatial and temporal mapping of fluid content, pressure, and geomechanical changes during production.

Production, well, and seismic data can provide good information in and around the wellbore as well as across the reservoir. Historically, most data used to develop reservoir models originates from measurements taken before production. Thus, even an extended well test was unlikely to provide any meaningful indication of how the reservoir and overburden would evolve under the influence of production and secondary recovery.

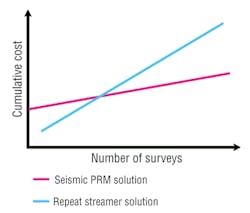

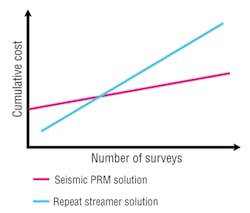

Cumulative cost of repeat streamer, WAZ, MAZ, nodal, or OBC surveys and seismic PRM solutions.

A variety of techniques have evolved to monitor the “factory” and assist in reservoir management. Time-lapse, or 4D seismic, the periodic acquisition of seismic data throughout the life of a field, is one such technique. The value of time-lapse seismic information is acknowledged, as even a modest increase of two percent in production often justifies the investment. Indeed, J. R. Waggoner says “the cost of 4D seismic is generally a small fraction of the economic benefit that can be expected” and that “given a careful 4D feasibility study and purposeful 4D acquisition and processing, there is essentially no risk that the (4D) project will not add value to reservoir management.”

That 4D monitoring has proven benefits is simple mathematics. There is a point where it becomes cost-effective to support a “life-of-field” monitoring and management program with the installation of a Seismic PRM solution. This is because over the life of a field the costs of repeated surveys above a permanently installed array cost less than repeated streamer surveys. And, this is without taking into account the additional value to reservoir management of the better quality data obtained from Seismic PRM. The better data is a result of the lower noise environment, better positional accuracy, and four-component data, all of which detect smaller changes in reservoir behavior.

In cases where multi- or wide-azimuth, or four-component data from nodes or retrievable ocean bottom cable (OBC) systems are required to image the reservoir adequately, the range of costs for repeated surveys can rise dramatically. This makes PRM more attractive over the life of the reservoir.

For such life-of-field solutions to be implemented, it is necessary to have both a through-life reservoir management strategy and an implementation plan, and Seismic PRM solutions that will endure the life of the field. With the recent emergence of proven, high-fidelity, optical Seismic PRM from companies such as Stingray Geophysical, CGGVeritas, and Petroleum Geo-Services, a significant shift in the way seismic reservoir monitoring is implemented is on the way.

The fiber revolution

Over 25 years ago, the introduction of fiber-optics for long-distance telecommunications revolutionized communications, laying the foundation for the digital world today. Expectations for digital communications are that they have a high capacity and are reliable to the point of always being available.

A similar impact on oil and gas exploration and production has started as the long-term reliability coupled with the small size and low weight of fiber-optic based systems makes large-scale sensing systems practical, both on land and offshore.

Designing systems for an expected operating life of 20-25 years is always a challenge, especially when it involves a large number of high-fidelity sensors and the infrastructure necessary to carry their data back to a recording system tens or even hundreds of kilometers away. It is even more challenging when the sensors are buried on the seabed where access for repair or replacement is time-consuming and expensive. Presently, there are two permanently installed Seismic PRM systems, both in the North Sea. Each has proven remarkably reliable, but being electrical inevitably brought failures which required expensive interventions alongside the cost of replacement sensing hardware. This results in step changes in the cost of lifetime reservoir monitoring strategies, yet even here PRM systems are economically more attractive than alternatives – again without considering the improved quality of information delivered.

Thus with the use of fiber-optic Seismic PRM, the risk and impact of potential system failures (as illustrated in 0) is alleviated, making the illustrated cost comparison profile achievable.

Optical components and fiber-optic based systems are more reliable inherently than their electrical equivalents, with mean time between failures (MTBF) typically expressed in hundreds of years for fiber components compared to thousands of hours for electrical components. It is not uncommon for fiber systems to achieve MTBF of tens of thousands of years, as evidenced by telecommunications. More relevantly, the technology used in Stingray’s Fosar Seismic PRM solution was developed for defense applications in the 1980s and 1990s. During that program, an array was deployed for 11 years without failure. In addition, accelerated aging tests, independent reliability analysis, and a flexible and robust optical architecture incorporating “bi-directionality” – the ability to continue interrogating a damaged or severed Fosar array from either end – allow equipment warranties beyond those offered by electrical systems.

Optical systems offer additional advantages beyond reliability. They have enormous capacity in terms of numbers of sensors, sampling frequencies, and data rates, enabling very large-scale sensing systems for both land and offshore applications. Powering such systems with electricity is a challenge, whether by alternating or direct current, by battery, or via direct connection. The power has to be generated, stored, and delivered to the sensing array. Over very large distances and sensor counts that could reach into the millions, this adds size and weight to the system, challenging the logistics of transport and installation. Fiber-optic systems powered by light require no electrical power to the sensor array. As a result, the size and weight of fiber-optic arrays usually can be tailored to optimize the efficiency of the transport and installation – whether on land, offshore, in deepwater, and in and around FPSOs and subsea completion equipment and flowlines. For example, the diameter of the sensing cable used in Stingray’s Fosar system ranges from a few millimeters to 18.4 mm (0.72 in.), depending upon the application and environment.

The need for large amounts of electrical power is also eliminated. For example, a 30,000-channel Fosar system requires 5.5 kW of power for the surface instrumentation and recording system.

Life-of-field planning, implementation

Time-lapse, or 4D seismic, is common in the North Sea, with many mature fields producing more and longer than first planned. The time between surveys is determined by several factors: the fidelity of the systems to detect small changes; the opportunity to change an infill drilling program; the planning horizon of most reservoir seismic programs; and the availability of workflows to respond to more frequent data inputs – at least until the reservoir does something the model did not predict.

On the assumption that:

- 1. We cannot “see” what is happening in the reservoir on a frequent basis (true)

- 2. That the reservoir model is a simplification of various parameters that describe reservoir behavior (true)

- 3. The reservoir behavior will change over time (true).

It makes sense to plan a seismic acquisition program to update the reservoir model and to feed into reservoir management strategies over the life of the field.

The three keys to planning a PRM solution are:

- 1. Quality of information

- 2. Risks of implementing or not implementing the monitoring

- 3. Economics.

Given life-of-field Seismic PRM, it is time to put in place reservoir monitoring strategies and implementation plans for the life of the field. Such plans require a different approach and need to account for the three key factors. Optimization requires a longer-term planning horizon than is common for most reservoir seismic activity and an approach that considers each key factor and addresses the monitoring as part of field engineering. Typically, such approaches commence with a feasibility study and move into a front-end engineering design phase so solutions specific to the field can be developed and tested for safe, effective implementation.

Quality of information

Reservoirs rarely behave in cycles that match drilling programs. The quest is to detect the smallest possible changes in reservoir behavior, fluid content, pressure, and geomechanics. This is done by matching the frequency of surveys to the minimum noise level within the data, ideally by minimizing the effects of noise due to the acquisition method, sensor location, and source repeatability. With permanently installed systems, it is possible to monitor the reservoirs passively, to detect seismic events generated as the reservoir “creaks and groans” while it produces. Passive seismic is an increasingly powerful diagnostic technique for active reservoir management.

It is important to identify and mitigate the risks of monitoring reservoirs. These occur during installation, post-installation, and throughout acquisition. There also are risks in not monitoring reservoirs or in using insufficient frequency. Stingray recently developed a technique to identify these risks, then represent them on a map of the field to aid decision making and analysis in the feasibility study stage of a PRM implementation plan.

Modeling the cost of various solutions and balancing them against the requirements for frequent high-fidelity information and the risks during and after installation allows an informed decision on how best to implement Seismic PRM.

Value

PRM solution enables the operator to make decisions that maximize value through optimized production, increased recoverable reserves, and lower through-life operating costs and reservoir uncertainties.

In the case of Seismic PRM, a significant element of the cost is generally borne up front, and the benefits accrue over a long period. Constrained capital budgets and net present value (NPV) calculations mitigate against installing such systems, even though the benefits are clear and the downside risks minimal. To address this, it is possible to apply lease financing to reduce the up-front capital requirement, convert costs from capital to operating expenses, and improve the NPV of projects where the lease finance rate is lower than the project cost of capital rate.

References

Quantifying the economic impact of 4D seismic, J.R. Waggoner, SPE 63133.

More Offshore Issue Articles

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com