FPS construction market expected to see slight increase in 2025

By David Boggs, Energy Maritime Associates

The floating production facility construction market remains one of the key bright spots in the offshore energy market.

Industry sentiment remains extremely positive, although down from last year’s record level. Project delays in 2024 have tempered optimism, while also allowing additional capacity in the supply chain and lower cost inflation.

Activity levels are expected to remain high from 2025-27, but new orders will continue to be challenged by project economics and geopolitical events.

The Global Floating Production Industry Survey, now in its twelfth year, gauges the current market sentiment as well as where the industry is heading in the future. Respondents come from all areas of the industry and from all parts of the globe.

Business outlook

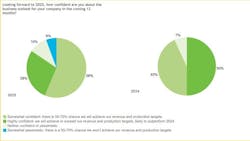

Sentiment in the offshore energy sector remains predominantly positive, with 84% of respondents expressing confidence in achieving their revenue and production targets this year. However, this marks a decline from last year’s record high of 93%.

After four years of increasing optimism, sentiment appears to be shifting. This year, 6% of respondents have a pessimistic outlook, compared to 0% last year, 5% in 2023, 8% in 2022, and 19% in 2021. Additionally, the percentage of highly confident respondents has decreased from 50% last year to 28% in 2025, which is similar to the 29% reported in 2023. Conversely, the proportion of those who are slightly optimistic has increased from 43% to 56%, significantly above the 48% reported in 2023.

While there remains great confidence in the outlook for the offshore energy sector, there is also a hint of caution as project awards have been delayed.

Here are a couple of quotes from the survey:

- Services Provider – “We’re generally seeing an upward trend in activity which needs to be considered alongside continuing geopolitical uncertainties.”

- Class Society – “Several projects in the pipeline. Hopefully will be awarded by Q2 2025.”

Cost inflation

While costs continue to increase, the rate of growth appears to be moderating. Two years ago, 40% of respondents believed that costs would increase by more than 10%. This dropped to 20% last year and 13% this year. Last year over 2/3rds of respondents expected 5%-10% cost inflation as compared to 59% this year. Over a quarter of responses this year believe that costs will grow by less than 5%, which is double that from 2024 and 2023.

The primary driver of cost inflation continues to be labor, with high demand for skilled engineers and construction workers. Commodities ranked as the second biggest factor, moving up one spot from 2024. This year, financing has replaced logistics as the third most significant factor in rising costs.

Expectations versus reality

Each year, we solicit respondents’ perspectives on future activity levels. Comparing last year’s projections for 2024 with actual activity reveals that expectations were overly optimistic, with all areas experiencing less activity than forecasted. This is perhaps unsurprising, considering that last year marked a record high in the survey’s history, with 61% and 70% of respondents anticipating high levels of activity for tendering and project management, respectively.

This year, respondents say they anticipate a slight increase in activity across the board in 2025, with levels expected to remain consistent through 2026. It appears that the industry may be transitioning towards more gradual changes, as opposed to the sharp boom and bust cycles observed in the past.

Greatest growth obstacles

Political issues returned as the greatest obstacle to offshore project growth, moving up from second place in 2024. These issues had been the top concern in 2022 and 2023, before being replaced by access to finance last year. Concerns persist regarding global conflicts, particularly between Russia and Ukraine, and in the Middle East. Additionally, changes in leadership in the US and UK have introduced further uncertainty.

Financing issues continue to be a major concern, as many banks have ceased or restricted funding for hydrocarbon developments. Consequently, contractors throughout the industry have turned to alternative sources of capital, such as bonds and infrastructure funds. This shift, combined with higher financing costs, has led field operators to alter their contracting strategies, with many favoring engineering, procurement, and construction (EPC) contracts over leasing. For some lease contracts, operators are offering pre-payments to reduce financing costs. To cut costs and increase competition, Petrobras is now looking to contract FPSO units on a build-operate-transfer (BOT) basis with a four to six-year period between construction and purchase.

Oil prices have re-emerged as a significant obstacle after three years of decline, rising from sixth place in 2024 to second place this year. This is consistent with recent trends, as oil prices have been dropping, and there are growing concerns about global demand amid China’s economic slowdown. Since August 2024, prices have mostly remained in the $70 per barrel range, down from the $80-$90 per barrel range seen in previous years.

Concerns about industry capacity have eased considerably, dropping to 9.3% from 16% last year. However, industry capacity remains a greater concern in 2025 than it was during 2021-2022 (5%-7%). Activity levels did not increase as much as expected in 2024, with delays in many project awards providing some additional breathing room.

Supply chain costs are a growing concern, with FPSO costs now ranking equally with environmental-social-governance (ESG) trends and investor sentiment issues (8.1% each). This marks a significant shift from last year, where ESG/investor sentiment was at 12%, and FPSO costs were at 3%. The unease with FPSO costs is reflected in the change from leasing to EPC and BOT contracting strategies. By comparison, other costs such as subsea (4.7%) and drilling (4.1%) are of less concern.

Potential bottlenecks

Shipyards have again been identified as the largest potential bottleneck, consistent with last year’s findings. Due to a booming shipping market, many shipyards are fully booked for the next two to three years, leading to the construction of offshore vessels increasingly moving to yards that do not traditionally build commercial ships.

Fabrication yards have become a growing concern, moving from third place to second place. The increasing size and complexity of FPS topsides have limited the number of yards capable of building and loading out these massive structures. Additionally, these fabrication yards are also engaged in building modules for LNG terminals and other onshore facilities.

Offshore installation remains an issue for 10% of respondents, unchanged from last year. This is driven by consolidation in the transport and installation market, as well as competition from renewable and decommissioning projects.

Fears about subsea contractors and equipment have eased slightly. It had jumped up from eleventh place in 2022 to fifth place in 2023, to second place last year, before dropping to fourth place this year. This is likely driven by project delays in 2024 that have spread out expected orders.

Growth regions

Brazil remains the top growth region again this year, as it has been since the beginning of the Global Floating Production Industry Survey. Petrobras awarded over $8 billion in FPSO contracts in 2024 and has plans for at least six units to develop new presalt fields as well as replace aging FPSOs in the Campos basin. Independent operators are redeveloping older fields, while larger players such as Equinor and Shell are progressing new developments. EMA is tracking 20 potential projects in Brazil, which could require up to 32 floating production units.

Tied for second place are West Africa and South America (ex-Brazil), with 20% each. South America (ex-Brazil) has been growing in popularity over (up from 14% and 17% in the previous two years). ExxonMobil has placed orders for 6 FPSOs and has plans for an additional 4 units in Guyana (10 in total). In 2024, Total awarded the first FPSO for Suriname, which could also require multiple units. FID is expected in 2025 for the Sea Lion FPSO in the Falklands.

West Africa has growth prospects in mature areas like Angola, Nigeria, and Ivory Coast, as well as new discoveries in frontier areas like Namibia. These include FPSO as well as FLNG opportunities.

Respondents are bleak about the outlook for the UK North Sea, which dropped from fifth place to thirteenth place. This is driven by extension of the windfall tax which has effectively killed most potential developments.

FPS growth potential

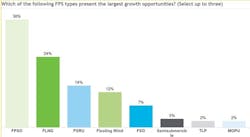

FPSOs remained the clear leader as the floating production system with the most promising growth potential, according to 36% of respondents.

After two years in second position, floating wind dropped to fourth place, receiving votes from only 12% of respondents, down from 25% last year. Enthusiasm for renewables has declined following cost overruns and cancelled projects.

Conversely, prospects for FLNG have increased, according to 24% of respondents, up from 13% last year. In 2024, Cedar LNG ordered a 3.3 mpta unit from Samsung/Black & Veatch. In 2026, Golar’s Hilli Episeyo FLNG is scheduled to be relocated from Cameroon to Argentina. Golar also placed a $1.6-billion contract with CIMC-Raffles to convert an LNG carrier into a 3.5 mpta unit. EMA is tracking 17 projects that could require up to 24 FLNG units.

Assessing the supercycle

The offshore oilfield service sector has experienced robust growth since 2021. Deepwater drilling rates have surpassed $500,000 per day, with stacked rigs being reactivated only for long-term contracts. Leading shipyards have full order books for at least the next three years.

When respondents were asked how much longer this growth cycle would continue, the vast majority expressed optimism. Nearly half of the respondents believe the sector will remain busy through 2027, while one-third expect it to last at least another three years (2028+). This sentiment aligns with the current floating production order book, which includes 60 units. One-third of these are scheduled for delivery within the next year, and another 25% are expected to be completed by 2026. New orders for large floating production units have anticipated lead times of four to six years.

Conclusion

The industry is expected to remain busy for at least the next two to three years, although there are growing concerns over political issues, oil prices, and rising FPS costs. Bottlenecks in experienced fabrication facilities and shipyards remain a potential problem.

Prospects for offshore hydrocarbon developments are brightest in South America (especially Brazil) and Africa. These are mainly FPSO and FLNG developments in mature as well as frontier basins. However, the outlook for floating wind projects has dimmed due to rising costs and canceled developments.