Improved management of risk, uncertainties

Darrell Knight, FutureOn

Digitalization advancesare helping engineering contractors design subsea field concepts in one-fifth the time taken by traditional project planning methods.

Developments in robotic process automation, Internet of Things (IoT) sensors, analytics and cognitive technology are increasingly addressing the industry’s problems of accessing data, converting data across expert systems, and visualizing data for offshore field layouts. Emerging technologies (sometimes called Industry 4.0) are transforming the way engineering, procurement, and contracting (EPC) companies conduct business by generating more field concepts in a much shorter time and eliminating inexact options. This is being accomplished using real-time data uploaded into the cloud to visualize the fields and run computations from a single source of data.

Compare this to the traditional approach. The basic bidding process would capture brainstormed ideas from engineers on flip charts and in PowerPoint and convert them into visuals via Visio, Corel Draw, and MS Paint. Then an outsourced engineering house would turn these documents into Computer Aided Design (CAD) files, with the drawn-out process stunting the EPC firms’ ability to meet tight design schedules and implement late changes quickly.

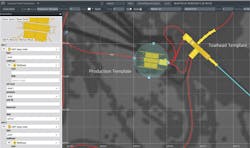

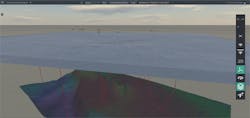

Cloud-based technologies such as FutureOn’s FieldAP and FieldTwin represent the next-generation of subsea project planning, bringing real-time data into plain sight through easy-to-use 2D/3D visualization in a collaborative web environment. Two key components that are revolutionizing the oil and gas bidding process are data visualization and data management, which allow greater collaboration, speed the design concept process, enable more meaningful decision-making, and reduce overall costs.

Screen shots showing different field development options. (All images courtesy FutureOn)

Faster pre-FEED

The visual rendering of complex real-time data streams increases an engineer’s responsiveness because the human brain processes images 60,000 times faster than it does text. Data visualization advances allow engineers to conceptualize, build, and approve pre-front-end-engineering design (FEED) field concepts three times faster and help engineers manage engineering IoT sensor data and risk management more effectively during operations.

Data management makes sense of the enormous influx of IoT sensor data and identifies discrepancies, leading to better business decisions and improved workflows. The work can be done more rapidly in collaboration with colleagues (both inside and outside of the company) and around the world, since everyone works from the same pool of real-time data housed in a single place. Furthermore, FieldAP and FieldTwin create a space within the engineering process for creativity without negatively affecting progress and allow solutions to evolve through a collaborative effort as opposed to the siloed approach of the past.

While global demand for oil and gas has created tight work schedules and, over the past year, an excess of projects to complete, tighter operating budgets have forced companies to rely on fewer employees in the immediate term to meet this growing work demand. The smartest and most future-focused, long-term-profit-driven companies have responded by exploring digitalization strategies to drive higher and better thinking from their engineering talent, fulfilling the business imperative of providing improved value to bring in revenues.

EPC companies design useful early concepts of offshore oilfield projects that are then handed off seamlessly to the construction teams and oil and gas operators to construct and maintain all in a matter of weeks, as opposed to the previous months, because teams can now produce from the same single data platform.

Reduced costs and time

It has become the standard operating practice for oil and gas industry to find new ways to reduce expenses in uncertain times. The oil and gas industry is now looking for new tools as well as new approaches to budgeting, forecasting, and reporting.

Typical digitalization approaches involve significant upfront expenditure. Deploying IoT devices, SMART sensors, and robotic tools require expensive new equipment purchases, employee training, and retrofitting of existing systems, and the return on investment can be difficult to assess. However, it is possible to pursue a more efficient and immediate digitalization strategy by investing in instantly implementable data-driven solutions that improve work processes and increase data accessibility and usability. FieldTwin deployed in real-world fields can reduce pre-FEED time and investment by as much as 60%, bringing a return on investment more quickly.

Contractors savvy enough not to feel threatened by digitization are deploying technology such as FieldAP to deliver faster delivery of more detailed concepts, including design options that give their customers choices they typically would not see at each stage of a project.

McDermott now uses both FieldAP and FieldTwin to build 2D and 3D fields directly in a collaborative web environment to rapidly produce many more concept designs for multiple fields that include essential information, such as flowline data. The company is developing concept proposals in 20-30% of the time taken previously for this process and can respond quickly to questions from operators and partners by accessing critical data directly.

The additional smart functionality of digitalization eliminates the pre-FEED CAD work during the proof-of-concept stage and the need to hire an outsourced engineering firm; an outsourced team of four drafters, working for two to three weeks, can cost up to $40,000.

As a result, field development enters FEED with a single, well-defined option with major design issues decided, risks and uncertainties understood, and the cost estimate, budgets, and schedules clear. Recently, McDermott designed and delivered four early design concepts to an oil and gas operator using FutureOn technology. Previously, the company’s team would likely only have produced one design because of the limitations of traditional design methods.

Darrell Knight.

Thinking ahead

If executives can harness the right technologies to support their business strategies and make better use of existing technology, there could be serious returns: up to $1 billion in cost savings or production increases, according to McKinsey. And the World Economic Forum has suggested that the digital transformation in the oil and gas sector could unlock $1.6 trillion of value for the industry.

So, industry futurists are saying that in the new era of energy, companies must move quickly to capitalize on this unique opportunity and stay competitive. Forward-thinking engineering companies that use these technologies can win more bids in an increasingly competitive environment in which operators expect engineering companies to absorb the field concept costs. Progressive engineering firms can now load accurate real-time data from real-world coordinates to build field concepts more rapidly, cost-effectively, and confidently with precise field options and real-time cost analysis.

The digitalization of offshore assets can seem like a leap into the unknown, but companies that make that leap begin to recognize how digitalization can empower them to accomplish more, particularly in making more profitable and prompt decisions in the field. There is now an eagerness to learn how using smart, cloud-based digital solutions to address daily decision-making challenges. Companies throughout the supply chain can see the competitive advantages that digitalization brings and are acting quickly to ensure that they do not get left behind. •