ONS 2024: Aker BP uses DrillDocs real-time rig surveillance technology

DrillDocs, a digital rig surveillance technology provider, has delivered real-time drilled cuttings size distribution data to Aker BP. The company’s camera-based computer vision technology was deployed on a contracted jackup rig while drilling a 1,000-m, 12¼-inch hole section on the Norwegian Continental Shelf.

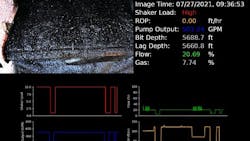

DrillDocs' CleanSight system employs Axis Communications' cameras designed for hazardous environments, which feature onboard processing capability for real-time image analysis.

DrillDocs’s image-processing algorithms continuously monitor drilled cuttings exiting the rig’s solids control system, calculating the amount and size distribution of recovered drilled solids. The company says this provides valuable information about hole cleaning performance, borehole stability and solids control equipment operations.

Before introducing DrillDocs’ technology, the rig equipment that separates drilled solids from drilling mud—known as shale shakers—was only monitored periodically by drilling staff making visual inspections. The company says this new approach allows the rig team to react in near-real time to events happening in the wellbore.

"Our technology captures and interprets unique and vital information about the drilling process that would otherwise go unreported," said DrillDocs CEO and Founder Calvin Holt. "By

combining advances in camera technology and computer vision, we’re able to spot drilling issues as they are occurring and allow drilling teams to take corrective action before they become much bigger problems."

Knut Eugen Svendsen, Aker BP's rig superintendent in Stavanger, added, “As this technology continues to mature, we foresee it becoming part of standard drilling practice on offshore and high-risk wells worldwide.”

At the Stavanger-based ONS 2024 event this week, DrillDocs is exhibiting at booth 4100 and Aker BP at booth 8380. View the ONS program to learn more about presentations by Aker BP and more.