John Waggoner • Houston

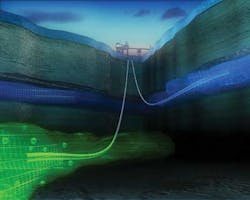

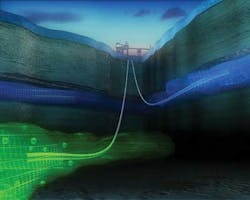

New technology opens door to MPD in ultra deepwater

Ultra deepwater may no longer be an impediment to managed pressure drilling (MPD) with the advent of new technology.

A major supplier of MPD services tellsOffshore magazine that a rotating control device is being developed for marine risers that will make it possible to expand the water depth capabilities of MPD into ultra deepwater.

The technology has been kept under wraps but a scientific paper on the topic is expected as soon as 1Q 2010.

That would be good news for ultra deepwater operators who risk losing productive time when a kick occurs. With enhanced control over bottomhole pressure, operators can also limit the potential for well damage due to excess mudweight.

Extending MPD capabilities into ultra deepwater has been limited by the very narrow margins between pore pressure and fracture pressure downhole.

Due in large part to the overburden of seawater and as the field matures the “pressure windows” for safe drilling become increasingly narrow.

According to the supplier, the technology being developed should make it possible to exploit these narrow “pressure windows” at greater depths. Probable markets for the technology are Brazil, the Gulf of Mexico, and West Africa.

Book explores methods for reservoir sampling

Downhole fluid analysis (DFA) is gaining disciples for wireline logging and is fast becoming a keystone in reservoir evaluation.

Mullins’ book on downhole fluid analysis provides insight into new optical technologies useful for reservoir studies. Shown here is a collection of fluid samples from around the world.

Schlumberger’s Oliver Mullins has written a book called “The Physics of Reservoir Fluids: Discovery through Downhole Fluid Analysis,” which provides an overview of the latest methods.

According to author Mullins, the discipline addresses the failed assumption that oil reservoirs consist of “one giant tank” of one homogenous hydrocarbon.

DFA uses relatively new but simple methods to find compositional gradients and to identify compartments. Moreover, the technology permits novel ways to establish reservoir connectivity with new data streams not employed traditionally.

Divided into two chapters, the book describes the growing body of data that DFA provides about reservoir complexities and discusses the scientific foundations for optical measurements through bulk optical spectroscopy, a technology not previously practiced in the upstream oil business. Mullins is reservoir domain champion for Schlumberger’s wireline headquarters.

The book can be ordered through the University of Texas (www.utexas.edu/ce/petex).

Petrobras tests CO2 reinjection for Santos basin pre-salt

Petrobras this month begins injecting high-pressure CO2 into the Miranga onshore field to test technologies for the Santos basin’s pre-salt cluster developments offshore.

The carbon dioxide produced at the future pre-salt fields will be re-injected into the reservoirs to boost the recovery factor, the company says.

The Miranga field project involves the geological sequestration and removal of 370 tons (336 metric tons) of CO2 from the atmosphere per day. National oil company Petrobras says the technology will considerably increase the recovery percentage of the oil nestled in the field’s reservoir.

The technique is based on injecting CO2 under high pressures. In this case, the CO2 works like a type of solvent that changes the properties of the oil and allows it to flow better through the reservoir-rock’s porous system.

Other alternatives, such as storage in caves or saline reservoirs, also are under analysis, Petrobras says.

Baker Hughes develops openhole annular isolation system

Baker Hughes has reached a new milestone for advanced completion designs.

The new MPas packer system allows operators to achieve selective zone isolation in open holes of extended reach wells.

Run on production casing or liner string, the MPas packer – plus the uniform production profile created by Baker Hughes’ BOT EQUALIZER inflow-control devices – enables flow in the annulus to be managed efficiently without the limits or risks associated with no isolation or more complex isolation methods, the company says.

The MPas packer provides improved time-to-seal control and a wider hole-size range than swelling rubber technology.

One of the innovations is the eTrigger controller technology, a method to electronically activate the MPas packer and simplify the job. eTrigger is computer programmed and once downhole, the controller activates the packer when the programmed temperature and pressure conditions are reached.

One operator offshore Qatar recently used the technology to achieve isolation in an extended reach well, eliminating the need for a fully cemented liner and perforations. As a result, the operator saved rig time and economized about $1.5-million on the project, Baker Hughes says.

Shell gets MMS approval for Beaufort Sea exploration

The US government’s Minerals Management Service (MMS) has approved, with conditions, Shell Offshore’s exploration plan to explore two leases in the Beaufort Sea. The Beaufort Sea is estimated to contain 8.22 Bbbl of oil and 27.64 tcf of natural gas (undiscovered technically recoverable mean estimate).

Shell proposes to drill two exploration wells during the July-October 2010 open water drilling season using the drillship M/VFrontier Discoverer. The plan includes a break in activities beginning Aug. 25, 2010 for bowhead whaling.