Installation costs balanced out by reduced opex

Pedro Viana

2H Offshore

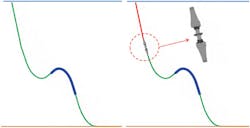

In most offshore settings, a flexible riser typically comprises one continuously manufactured riser section terminated with end fittings. However, a dynamic riser can consist of two or more sections with an intermediate flanged connection joining the end fittings of each section together, to suit transportation or installation purposes or even design requirements.

Outside the Brazilian sector, however, there appears to be a widespread lack of confidence in the use of intermediate connections in dynamic flexible risers. This is due to real but also perceived factors such as the introduction of an additional leak path, increasing risk; the higher cost associated with the additional section and hardware such as bend stiffeners; increased offshore installation time; restrictions in annulus monitoring; armor wire fatigue in end fittings; and a limited (published) track record of the performance of intermediate connections offshore.

In fact, the risks associated with flexible intermediate connections are mostly low, and can be mitigated through standard design and fabrication procedures. Early specification of an intermediate connection during design allows for optimization of the global riser configuration and intermediate flexible structures. The additional hardware and installation costs imposed by an intermediate connection can be balanced by direct and indirect cost savings. Beyond single projects, intermediate connections can also form an integral part of a wider integrity management and standardization approach for flexible risers or even hybrid risers, facilitating the connection to a steel or composite pipe.

Globally there are around 300-400 risers in operation that are fitted with intermediate riser connections, in water depths ranging from 400-2,250 m (1,312-7,382 ft). Between 80 and 90% are in Brazilian waters, most servicing Petrobras platforms. The Brazilian national oil company owns the majority of the flexible risers and flowlines installed to date, often employing up to six flexible sections within one riser. The number of sections tends to increase the deeper the water, with intermediate connections featuring in most of the flexible risers in the ultra-deepwater presalt areas. Consistent use of flexible risers with intermediate connections is not only a result of the specific needs of that operator, but is also down to broader strategic decisions related to design standardization and installation, which rely on the use of intermediate connections.

Managing risks

Risk perception varies among operators and offshore region. Clearly, there is an intrinsic risk when introducing a connection point to a structure because of the potential additional leak path.

As with any flanged connection, a back seal test is performed to assure connection integrity during installation. Flanged connections are a well-understood design solution with a broad track record in subsea environments. Within a flexible riser line, they are placed in sections with reduced dynamic movement, typically where either no bend stiffener is required or only one of a reduced length, in order to limit the risk of fatigue failure. Excluding cases with material incompatibility issues, a flanged connection presents a risk, but one that is controlled and restricted.

A hardware element considerably more complex than the flange connection is the end-fitting assembly. Each manufacturer has its own design, but all designs share the inherent risks associated with the manual process of sealing and locking the multiple steel and polymeric layers, including the individual tensile armor wires. The end-fitting assembly is one of the critical areas of concern for flexible riser integrity, and requires particular care during fabrication and installation. During operation, most of the issues with the end-fittings arise under high tension, in particular when subjected to cyclic fatigue loads found at the riser top or the touch down zone. Placement of an intermediate connection and associated end-fittings should avoid the fatigue-critical locations along the riser - this can be achieved without major issue as long as it is considered early during design.

Another operational risk worth reviewing when considering use of intermediate connections is the potential contact between flexible risers, or other structures, placed in close proximity. Some low-energy contact between flexible riser structures is usually acceptable, but the contact between a flexible riser and a flanged connection could cause damage to the riser’s outer sheath and the layer of armor wires underneath. In such cases, protective covers can be adopted, although these tend to increase the drag area and contact diameter, and consequently the risk of clashing. It is advisable, therefore, to avoid intermediate connections in regions with potential for contact with adjacent structures.

An intermediate connection, it should be stressed, is also a risk limiter. Any structural or sealing failure during the factory acceptance test, installation, or operation of a flexible riser could compromise the whole structure. Flexible risers are often longer than 2,000 m (6,562 ft), with the top 30 m (98.4 ft) or the 100-m (328-ft) touch down zone commonly being the critical sections. If the riser is split into multiple sections, damage to any of these critical sections is not likely to compromise the whole riser line. The replacement of a damaged section can be performed offshore, limiting production losses. Even when a damaged riser is composed of a single section, an offshore section cut and re-termination of the line (with or without an additional riser section and associated intermediate connection) is a field-proven solution. However, the offshore re-termination and inclusion of an end-fitting is best avoided, as the quality of the end-fitting manual assembly will never be as good as the one achieved in a controlled factory environment.

Design optimization

A flexible riser is typically a bespoke product in which the type and number of layers and their characteristics are combined to suit project-specific needs. Achieving a standard solution for the top and bottom sections of a riser is a challenge due to the different loads and pressure requirements. Optimizing the design of the structure (or layers) in terms of in situ performance becomes more challenging the deeper the environment and the more demanding the overall project requirements.

An intermediate connection can also serve to optimize the design, or provide a solution, for risers with a high permeation rate from the bore to the annulus. In a design where a single-section riser would have the annulus filled up by condensate to the top critical section, a split riser might benefit from the lower permeation at the top section (due to the lower temperature and differential pressure). Additionally, the design may allow for a different layer arrangement and increased annulus volume to ensure the top armor wire annulus section stays dry throughout the field’s life, leading to a much improved fatigue performance.

Another consideration might be the maximum installation length, often limited by the available installation reel capacity. In cases where an operator has contracted multiple day rate vessels or is looking to increase the installation vessel availability, limiting a section’s length to allow for reel-lay can avoid the need for carrousel-fitted installation vessels, which often command higher day rates.

Cost controls

The cost implications of an intermediate connection can be considerable, especially for small-scope projects. However, the added outlay can be minimized through planning early on in the design phase to incorporate some of the advantages discussed above. Hardware and installation costs can be further balanced by capex and opex benefits arising from standardization, integrity management, and life extension.

End-fittings are not only an expensive long-lead item, but also are often the most critical part of the flexible riser for fabrication, transport, and installation, requiring careful handling at all stages. The additional offshore installation time incurred for an intermediate connection depends on multiple factors, including the capability of the offshore crew, but is typically one to two days. An alternative option could be a continuous single riser section installed using a carousel-fitted vessel, with no need to stop the riser lay for make-up of the intermediate connection; however, the installation vessel would have to sail to the spool base for trans-spooling and loading of the line onto the carousel, which also involves time and cost.

If the intermediate connection is driven by the need for different flexible structures, the additional cost for manufacturing set-up and fabrication of shorter lengths of flexibles can be prohibitive. On the other hand, the requirement for one line can lead to optimization and standardization for multiple lines, with longer lengths manufactured and employed across different risers’ sections and eventually in flowlines.

Through applying an existing design to a top riser section with an intermediate connection, the time to first oil can be significantly reduced. The resultant cost savings can allow for a top-section design with a fatigue life below the field requirement, making it commercially feasible to replace just the top section at a future point.

Standardization

Flexible riser technology is constantly evolving. Standardization is an intrinsic challenge, further complicated by each project’s specific requirements, but standardization does bring direct cost benefits and technical and integrity management efficiencies.

Whether driven by the project design team or the manufacturer, standardization can be applied in a single development, or can be considered more broadly for multiple developments or regions. When a riser comprises multiple sections, this allows for discrete standardization through the intermediate structures. In other words, any riser configuration can be made up of different combinations of similar, pre-qualified structures, or there may only be a need for qualification for a certain section.

For multiple fields, the benefits increase and the delivery time for the flexibles can be expedited, eventually with a need for only limited engineering. Standardization combined with replacement or re-termination of a flexible top section also increases the overall versatility of the flexible riser solution. For instance, a spare riser section that suits multiple fields becomes more viable. Additionally, re-use of flexible sections which have not exceeded their fatigue life can be an attractive long-term proposition.