Lars Herbst, MMS

Operators continue to push the boundaries of deepwater drilling and production in the Gulf of Mexico. In February 2003, the Minerals Management Service (MMS), the federal agency that manages energy and mineral resources on the outer continental shelf, reported that at the end of 2002, there were 65 projects producing in water depths greater than 1,000 ft (305 m) in the GoM. Five years later, the number of deepwater producing projects in the Gulf had doubled to 130.

In 2007, approximately 72% of the GoM’s oil production and 38% of its natural gas were from wells in 1,000 ft of water or greater. And for the first time in history, all 20 of the highest producing blocks in the Gulf were in deepwater.

“As we look at the data, it’s clear that deepwater advancement is occurring in all areas – leasing, drilling, and production,” says Randall Luthi, director of MMS.

Meanwhile, technology is evolving to keep pace with demand. In 2007, MMS approved the use of 15 new technologies in the Gulf region. Four examples of the new technologies include the OmniMAX anchor; the use of pre-set polyester moorings for deepwater drilling rigs; a disconnectable, internal turret mooring system for ship-shaped floating production systems; and various forms of subsea boosting, including subsea pump systems for enhanced hydrocarbon resource recovery.

Active deepwater leasing, exploration

Unprecedented leasing activity was seen in the October 2007 and March 2008 lease sales. In Central GoM Lease Sales 205 and 206, nearly 70% of the tracts receiving bids were in water depths greater than 1,300 ft (396 m). A high number of newly available deepwater leases, which had expired under their initial 10-year term, contributed to this active bidding. MMS considers “newly available tracts” to be those that were not available for lease in the prior year sale for the same planning area.

In the 1996 and 1997 lease sales, 47% and 62% of the tracts awarded, respectively, fell in the greater than 800 m (2,625 ft) water depth range. About 40% of the tracts awarded in greater than 800 m water depth in the 2006 and 2007 sales were leases that expired, terminated, or relinquished from the 1996 and 1997 sales.

Currently, 54% of the active leases in the GoM are in water depths greater than 1,000 ft. With the high interest in the deepwater tracts available in Sales 205 and 206, this percentage of deepwater leases likely will increase when the fair market value analyses are complete and the leases awarded.

Deepwater drilling also is on the rise. In 2007, 142 wells were spudded in water depths greater than 1,000 ft; 66% were for exploration. Twenty-four of those wells were in water depths greater than 7,500 ft (2,286 m), a record for that water depth range in any one year.

Operators announced eight deepwater discoveries in 2007. The deepest was in Desoto Canyon block 353 in 7,457 ft (2,273 m) of water. These discoveries follow an active 2006 year in which 12 deepwater discoveries were announced.

Announced deepwater discoveries in 2007

Map shows deepwater projects that began production in 2006 and 2007, and those expected to begin production by the end of 2013. These represent only the projects for which the operators have announced plans; more are likely to begin production in the next few years.

Meanwhile, 48 deepwater development wells were drilled in 2007, up 41% from 34 deepwater development wells drilled in 2006.

In 2007, a record was set for the highest number of rigs drilling in ultra deepwater (greater than 5,000 ft [1,524 m] water depth). In July, 15 rigs were drilling in this water depth range with the deepest in 8,694 ft (2,650 m) of water at Alaminos Canyon block 731.

Active deepwater exploration and production is expected to continue given the number of new rigs being built with capacity to drill in up to 12,000 ft (3,658 m) of water to 40,000 ft (12,192 m) deep. At least 13 of those newbuilds already are contracted and expected to be ready to work in the next two to three years.

Subsea, hub trend

As deepwater production increases, the trend is to use subsea completions and the hub concept as the most efficient way to produce where there is no established infrastructure. In 2007, 15 new deepwater projects came online. Nine of those are being produced through theIndependence Hub, which recorded first production in July 2007.

The number of completions in deepwater has steadily increased since 2003. In 2007, there were 45 subsea completions. This is a record for the number of deepwater completions in a given year, illustrating industry’s ability to tie-back smaller prospects to either existing infrastructure or new hub-type facilities.

The latest approved method of hub development in the GoM is the FPSO facility. The MMS has approved the use of an FPSO in development plans for the Petrobras-operated Cascade/Chinook project in the Walker Ridge area in 8,200 ft (2,499 m) of water. Still awaiting additional approvals before production may begin, this will be the first use of an FPSO in the US Gulf and the first production from deep discoveries in the Lower Tertiary trend.

Meanwhile, another first for the US GoM in hub development is expected in early 2009 with the installation of Helix Energy Solution’s ship-shaped, DP, disconnectable floating production unit,Helix Producer I. The unit will be installed on the Helix-operated Phoenix field in Green Canyon block 237 in 640 m (2,100 ft) of water.

New technology

In order to reach untapped reserves in the Lower Tertiary trend and in other deepwater areas, technology continues to evolve. Following are descriptions of some of the newly-approved technologies for use in the GoM.

OmniMAX anchor and mudrope. Delmar’s OmniMAX anchor (U.S. Patent No. 7,059,263) is a gravity-installed, vertically loaded anchor (VLA) with a high modulus polyethylene (HMPE) mudrope forerunner. The anchor is capable of being loaded in any direction – 360° around its axis. Under extreme loading and uplift angle, the anchor will penetrate deeper into the seafloor to gain holding capacity.

Number of shallow and deepwater subsea completions by year

MMS approved the use of the OmniMAX anchor and mudrope system on Dec. 12, 2007. The first OmniMAX anchor installation for offshore oil and gas use in the GoM was completed on Dec. 30, 2007, in Garden Banks block 667 for use with Diamond Offshore’sOcean Star MODU. This marks the first time a gravity-installed VLA was deployed successfully for offshore OCS use.

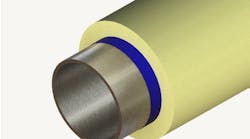

Pre-set polyester mooring for deepwater drilling rigs. Although the use of polyester mooring lines for station-keeping on production facilities still is considered new technology in the GoM, it is common practice to use this type of technology on MODUs. One stipulation MMS has required of operators for allowing the use of polyester moorings traditionally has been that the synthetic rope may not come in contact with the seafloor. This requirement limits particle migration into the load-bearing fibers of the rope. In recent years, the oil and gas industry has requested permission to pre-set MODU mooring lines. This procedure results in the rope being laid on the seafloor until the rig is connected to the moorings.

Since these lines can be inspected more frequently (generally after each drilling campaign) compared with those of permanently fixed production facilities, MMS was willing to consider these requests. After conducting extensive research on the jacket and filter layer of the synthetic rope, MMS has granted approval for operators to pre-set polyester mooring lines for MODU’s with the stipulation that the lines be visually inspected each time they are retrieved. Polyester mooring lines for permanent facilities still are not permitted to touch the seafloor, but MMS has extended the time between scheduled insert removals/testing for these facilities.

Top 20 producing blocks in 2005 and 2006

Disconnectable internal turret system. The turret is the primary interface between a weathervaning, floating production facility and the stationary mooring, riser, and subsea systems. The turret acts as the primary load path between these systems. Since the production facility may not be designed to stay on location during a severe storm or hurricane, the turret can be disconnected to allow the facility to sail away from its mooring system. The turret and subsea systems remain on location at a safe depth below the water’s surface.

The concept of a disconnectable, internal turret system was approved by MMS in the conceptual plan for the Cascade/Chinook development. MMS will require that a bubble-tight, shut-down valve remain with the submerged buoy and a separate bubble-tight, shut-down valve remain with the facility. MMS also will mandate that the piping between these valves be able to be flushed before a planned disconnection to prevent release of any liquids to the water.

Subsea pumping and separation. Subsea pumping and separation have been identified by the industry as key enablers in improving ultimate recovery from deepwater fields in the GoM. MMS has approved one application for the King field, which involved subsea pumping operations. MMS is currently evaluating two other applications: the Perdido Regional Development hub for subsea pumping and Cascade/Chinook FPSO for a combination of subsea pumping and subsea separation. The pumps will boost the operating system pressure, lowering flowing tubing pressures at each well, thereby increasing flow rates. Shell, BP, and Petrobras are just a few of the many operators using or considering the use of subsea boosting to increase production and extend field life, ultimately increasing hydrocarbon recovery.

Two subsea pumps and associated equipment were installed by BP on the King field. This installation set a new record for both water depth and tie-back distance. The pumps are in approximately 5,500 ft (1,676 m) of water and more than 15 mi (24 km) from their host, theMarlin TLP. The pumps were put into service in December 2007.

Meanwhile, MMS is working with API on the regulatory framework for installation of a high-integrity pressure protection system (HIPPS) in the GoM. A HIPPS provides alternate over-pressure protection for a pipeline or flowline associated with wells with shut-in tubing pressure of greater than or equal to 15,000 psi and/or 350° F (177° C). The system employs valves, logic controllers, and pressure transmitters to shut down the system before the pipeline is overpressured and/or ruptured. A recommended practice for HIPPS is expected by the end of this year.

The continued advancement in technology for leasing, exploration, and production of the deepwater Gulf plays an essential role in US energy security as offshore operators meet the challenges presented in exploring and developing this energy frontier. “The Gulf of Mexico is a key energy producer and the safe and environmentally responsible development of our resources is vital to the economy and our way of life,” says Randall Luthi, director of MMS.

Author’s note

Additional data and analysis can be found in the MMS report, Deepwater Gulf of Mexico 2008: America’s Offshore Energy Future which was debuted at the recent Offshore Technology Conference in Houston. MMS issues its full report analyzing data concerning activity in deepwater GoM, considered to be greater than 1,000 ft water depth, bi-annually. A smaller interim report is published in the alternating year.

Copies of the new deepwater report can be obtained from MMS, free of charge, either in paper or on a single compact disc, by visiting the MMS Public Information Office, 1201 Elmwood Park Blvd., New Orleans, Louisiana.

You can telephone 1-800-200-GULF or 504-736-2519 local. Ask for OCS Report MMS 2008-013, Deepwater Gulf of Mexico 2008: America’s Offshore Energy Future. The entire report, in Adobe’s PDF format, can be found atwww.mms.gov.

About the author

Lars Herbst is the MMS regional director for the Gulf of Mexico OCS Region. Herbst manages the leasing of OCS lands for oil, gas, and other mineral development, and supervises the regulation operations and protection of the environment on those leases that involve 4,000 platforms. This area covers five Gulf Coast states. Herbst manages a staff of 500, which includes geologists, geophysicists, petroleum engineers, biologists, and environmental scientists. Previously, he served as acting regional director and as regional supervisor for field operations. Herbst is a registered professional engineer in the state of Louisiana and holds a BS degree in petroleum engineering from Louisiana State University.

New guidelines for hurricane season

MMS has adopted new guidelines for drilling and production during the hurricane season. For jackup drilling, the MMS will use:Recommended Practice 95J, Gulf of Mexico Jackup Operations for Hurricane Season – Interim Recommendations, First Edition (API RP 95J). This guidance, effective June 1, covers drilling, workover, and completion operations. The MMS will use this document to review and evaluate information submitted in each APD or APM.

For moored drilling, the MMS will use:Gulf of Mexico Mooring Practice for Hurricane Season (API RP 2SK, Appendix K). This guidance, effective June 1, also covers drilling, workover, and completion operations. If an APD or APM with a moored rig already has been approved for drilling between June 1 and Nov. 30, submission of a revised application is required. MMS will use the new mooring guidance to review and evaluate the information submitted in each APD or APM.

Effective May 21, all drilling units and permanent equipment and facilities that are attached to an OCS production platform with tie-down components are subject to:Bulletin 2TD, Guidelines for Tie-downs on Offshore Production Platform Facilities for Hurricane Season, First Edition (API Bulletin 2TD).

For more information:http://www.gomr.mms.gov/homepg/regulate/regs/ntls/ntl_lst.html