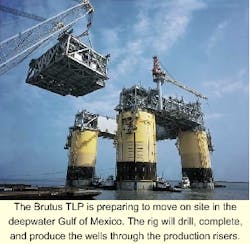

COMPLETION TECHNOLOGY: Brutus TLP development wells drilled through production risers

The Brutus TLP is preparing to move on site in the deepwater Gulf of Mexico. The rig will drill, complete, and produce the wells through the production risers.

Shell's previous tension leg platforms (TLP) for the producer's deepwater developments in the Gulf of Mexico have had a well count between 16 and 24 wells. Brutus, the producer's latest TLP version now being assembled, has only an 8-well template. Why the difference?

When the development decision for Brutus was being made, oil prices were about $10/bbl. Keith Craik, Brutus Well Systems Project Leader, said that low oil prices make cost control very important. With the lessons learned from previous TLPs, it was determined that Brutus reserves could be produced with fewer wells. It was also decided that more cost savings could be gained by drilling through the production riser.

Shell drills wells from a direct vertical access (DVA) platform, such as a TLP, with a 21-in. drilling riser and a 13 5/8-in. inner riser to handle the higher pressure zones of the well. After the production liner is run, the well is temporarily abandoned, the drilling and inner risers are retrieved, and the production riser and production casing tieback is installed. The well is then completed and subsequently produced.

Before the TLP is brought on site, batch drilling is performed by a mobile offshore drilling unit (MODU). The goal of the batch drilling is to set casing past the shallow water flow zones, before temporarily abandoning the wells. The TLP is then installed. Then the TLP drilling rig finishes the well drilling and completion operations.

One well, one riser

The original well design on Brutus called for batch drilling through the 16-in. tophole interval. But Craik said these wells had a short 13 5/8-in. casing interval. He said Shell felt that by adding this interval to the batch program and drilling this section from a MODU, Shell could eliminate the 21-in. drilling riser, the inner riser and the drilling riser tensioning system on the TLP and could use a smaller 13 5/8-in. drilling riser.

After examining this option, it was decided that with several modifications, the contractor could drill, complete, and produce the wells through this riser. This would eliminate the need to purchase a drilling riser, the inner riser, and the riser tensioning system, for a significant cost savings.

In addition, using one riser for the combined operations would save a substantial amount of time since it would eliminate running and pulling the drilling riser and temporarily abandoning the well. "That drilling riser runs pretty slow," he said.

Craik estimates this saved 12 days per well, once the TLP was on location. The production risers have their own tensioning system, but by upgrading this to handle the combination risers, all the other equipment was eliminated.

Fit-for-purpose riser

The fit-for-purpose riser for these wells was 10 3/4-in. for the TLP. This is as big a riser as the projected well completion would require. But for the wells where the combination risers were used, there was the additional cost of moving from a 10 3/4-in. riser to a 13 5/8-in. riser and upgrading the riser tensioning system.

Still, production acceleration and savings in drilling riser equipment more than offset the added cost of the additional batch drilled section, and the riser and tensioner upgrades. "When we did the analysis, it was obvious this was a money-making proposition for us," he said.

TLP completion and production techniques are evolving, Craik said. To make the move from production riser to the "combo" riser required an extensive risk analysis and comprehensive Hazop. The more TLP units that Shell places in service, the more comfortable the producer becomes with core technologies. This allows the application teams to progress to other areas of technical development, such as the combo riser.

Other applications

While Brutus appears to be a good application for the combo riser approach, Craik said this is not a universal solution. "You have to look at it on a case-by-case basis," he said.

The use of the combo riser is casing-dependent. While others have drilled through their production risers to conduct a workover or perhaps a short sidetrack, this is thought to be the first time a well has been designed to be drilled, completed, and produced through one riser.

The combo riser was specifically designed to prevent wear and fatigue encountered in the drilling process. Procedures were designed to minimize the wear and damage to the riser. The differences in this riser are subtle.

Craik said it looks like Shell's other production riser. "For the most part they are interchangeable," he said. The combo riser tensioners are designed to handle heavier loads, but the connectors and the material are essentially the same as those used on other Shell deepwater projects.

The hardware is not what makes the difference, Craik said. It is primarily the approach to the drilling and well-control processes that gives Shell the confidence to use the same riser for all three activities.

Smaller deepwater fields

Looking ahead, Craik said he does not know when this design will be used again. However, he did say Shell is looking at this riser solution for a certain class of projects. This can be seen as an enabling technology in deeper water, Craik said.

For smaller fields in deepwater, an operator would like to use a smaller platform. Topside and rig weight in deepwater can cost as much as $5/lb to support. If the 21-in. drilling riser can be eliminated, and a smaller riser used for drilling, completion, and production, a smaller rig can be used.

The time savings associated with the combo riser can also reduce time to first oil. If smaller prospects can be brought on line faster, with a more cost-effective DVA solution, it might expand the number of fields that can be economically produced in deepwater. This is important, since there is a limited number of giant fields with accumulations large enough to justify a full-blown TLP installation. The combo riser gives Shell another option to consider when evaluating how to approach a marginal field in deepwater.