COMPOSITE RESEARCH: Composite tethers and risers in deepwater field development

The joint was shipped offshore and was successfully installed and pressure tested for the first live well 6507/8 A-41 on 26th of July 2001.

For deepwater developments with floating structures, the use of lightweight and high-strength materials has become increasingly important. Increased water depth generally means increased weight and tension from risers and station keeping systems. These effects have to be compensated with additional buoyancy, which results in increased displacement and dynamic mass of the floating structure. This requires larger stationkeeping systems, and the design spiral continues until convergence is achieved.

Generally, the use of composites and advanced materials reduces the requirement for increasing the displacement. This effect becomes more important as the water depth increases. The cost benefits gained by introducing composites are dependent on the type of concept and where the substitution takes place.

The more weight-sensitive the concept is, the larger the gain will be. The most sensitive floating concepts are the tension leg platform (TLP), followed by the semisubmersible. The least sensitive is the floating production, storage, and offloading (FPSO) vessel.

Through the Conoco/Kværner Composite Alliance, the two firms have performed significant work to assess the global impact of the use of composites on overall platform configuration. The costs associated with composite applications, and the cost reduction for the entire system when substituting composites for steel, has also been extensively investigated. The reduction of the system cost is important since the procurement costs for composite components are generally higher than equiv- alent steel components by a factor of 1.5-2.0.

Several studies have shown that the use of composite materials in risers and tethers has many benefits and that the market potential is large. The current plan is to complete by the end of 2001 programs for the demonstration of full-scale fabrication and installation of both composite risers (CompRiserTM) and composite tethers (CompTetherTM). In addition, systems for certification and quality control will be established according to Det Norske Veritas (DNV) design guidelines for composites offshore.Composite technology

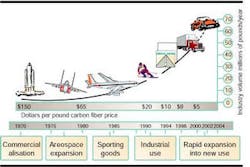

Today, carbon fiber composites are being used in high volume applications such as in the construction, marine and the automotive industry.

Because of the potential savings from reducing weight of offshore structures, extensive effort has been devoted in expanding the use of composite materials. These materials consist of small diameter fibers of high strength and modulus embedded in a matrix with bonded interfaces which permit the fibers and matrix to form a new material which captures the desirable characteristics of each. The fibers are the main load-carrying member while the matrix maintains the fibers in the preferred orientation and acts to transfer load into the fibers plus protect the fibers from the surrounding environment.

The most common fibers are glass, carbon and aramid. Polymeric matrix materials can be thermoset or thermoplastic. Fibers are incorporated in the matrix in long continuous lengths or are sometimes utilized as short discontinuous fibers. Composite components are formed by stacking several laminas (single plies) to build up a composite structural laminate. The properties of a composite material depend on the properties of the two main constituents: the fibers and matrix.

Two important factors for the increased use of carbon fiber composites in the recent years are the reduced cost of raw material and the development of efficient and more reliable production methods. Today, carbon fiber composites are being used in high volume applications such as in the construction, marine and the automotive industry.

The main advantages that composites offer for offshore applications are high specific strength and stiffness, lightweight, corrosion resistance and good fatigue performance. In addition, composites permit greater design flexibility for tailoring properties to meet specific design requirements, and thus promoting better system-oriented, cost-effective solutions. Also, the carbon fiber has superior properties to steel when the weight is taken into account.

For composites, the properties of the laminates very much depend on the way it is produced. Automated processes have been used when producing the laminates (pulltrusion and filament winding, respectively). Both of these processes are conventional processes with computerised control of the manufacturing parameters. Hence, the manufacturing process is easily repeatable and, thus, ensures consistent laminate properties.

TLP case study

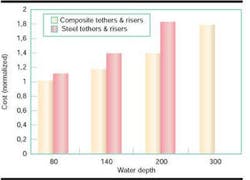

The total CAPEX of the TLP is less for all water depth using composite tethers and risers.

The TLP concept is a proven technology with an established track record over the last decade in water depths up to 1,000 meters. However, for water depths greater than 1,000 meters, the weight of the tether systems and the pretension requirements of conventional steel production risers increase significantly and start dominating the entire global configuration of the TLP. This makes the TLP concept less economically attractive than other field development solutions.

Based on the good track record of TLPs and the fact that significant savings for TLP composite applications were identified in a holistic study, a TLP benchmarking case study using composite tethers and risers and steel tethers and risers was carried out. The main objectives of this study were to evaluate the impact of using composite risers and tethers on the overall TLP configuration, to assess whether a step change in TLP application could be confirmed with respect to water depth and to determine the impact of composites on the overall TLP capital expenditure.

The case study considered mini-TLPs. The mini TLP is a wellhead platform, accommodating a minimum process, utility, and drilling equipment. The unit's main function is to provide dry wellheads and hydrocarbon transportation to a process platform. Deepwater developments will typically comprise of several wellhead platforms in conjunction with a large process facility (FPSO). It should be noted that for large TLPs, the benefits of using composite tethers and risers are even more pronounced.

The TLP study was carried for four water depths (200 meters, 800 meters, 1,400 meters, and 3,000 meters) in a typical Gulf of Mexico environment. The riser tension is based on 12 production risers. The effect of composite risers and tethers on the overall displacement is substantially reduced as well as the required pre-tension level for the 12 risers.

The TLP case study confirms the potential benefits of using composite risers and tethers for a TLP. The main reason is that the composite risers and tethers are nearly neutral buoyant, hence the displacement of the TLP is constant. In addition, the study has also verified that the well-proven TLP technology can be extended to at least 3,000 meters water depth. In comparison, a conventional steel tether system is limited to 2,000 meters water depth.

Tether technology

Since 1998 studies and laboratory testing have been carried out in order to develop the composite tether technology. The main components of the tether system are the tether body and the top and bottom connectors. The tether body consists of a number of small diameter carbon fiber rods bundled together into strands. The strands and tethers are slightly twisted when assembled in order to enable spooling.

For TLPs with conventional steel tubular tethers, the tether loads are monitored using complex underwater load cells or electromagnetic devices. The load cells are expensive and can be unreliable. Fiber-optical sensor technology has been developed extensively in the past few years, and different optical sensing methods are now being used in several applications offshore (downhole measurement system). The use of optical sensor technology has also been successfully demonstrated so the load monitoring of a composite tether can be carried out with a large accuracy and at a cost that is significantly lower than a conventional tether load monitoring system.

A 130-meter prototype has been manufactured at KOP's existing steel tube umbilical facility in Moss, outside Oslo, Norway. It was demonstrated that manufacturing of the tether can efficiently be done utilizing the same process as for assembling steel tube umbilicals. Only minor modifications had to be done on the process line in order to change from umbilical to successful tether manufacturing.

Riser technology

The 22-in. composite drilling riser is ready for offshore installation on Statoil's Heidrun TLP in the North Sea.

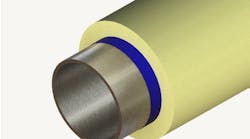

The KOP/Conoco Composite Alliance has been involved in three studies involving design and qualification of production, low-pressure drilling and high pressure drilling composite risers. The main features of the composite production and drilling riser joints are the metal connector, a metal/elastomeric liner, the structural carbon fiber composite laminate and the external protection layer. The structural composite and the metal connector are connected mechanically by the "TrapLock." An internal metal liner is applied when resistance to mechanical damage by running tools is required.

The riser is fabricated using the filament winding technique. The fibers go through a resin bath before they are wound onto the metal assembly. The process is computer controlled, to ensure accurate application of the laminates. As part of the effort to qualify the manufacturing process, some riser joints were instrumented with optical fibers that have been filament wound into the composite.

A cost comparison between TLPs with composite risers and tethers, versus steel risers and tethers, indicates that the cost of composite risers is slightly more expensive, whereas composite tethers (even for the 800-meter water depth case) are cheaper than conventional steel tethers, mainly due to the reduced installation cost.

The total capital expenditures of the TLP is less for all water depth using composite tethers and risers. For the 800-meter water depth case, the total capital cost is reduced by approximately 11% when composite risers and tethers are used. This saving increases to 25% or about $60 million for the 2000-meter water depth case.

Heidrun demonstration

Followed by an extensive test and qualification program, a 15-meter, 22 in. high pressure composite drilling riser joint will be used in drilling operations on Statoil's Heidrun TLP platform in the North Sea. The riser field joint will be exposed in three live wells at the Heidrun TLP. It will be run at three different locations in the riser string.

For the first well, the joint is currently placed just above the tapered stress joint. For the second well, the joint will be placed mid-string, and in the third well, placement will be just below the splash zone. The joint will be exposed to drilling operations for about 45 days on each well.

The joint was shipped offshore and successfully installed and pressure tested for the first live well 6507/8 A-41 on 26 July 2001. While this well is being drilled, the tensional loads and internal pressures felt by the joint will be continuously recorded.

Composite drilling joint

Titanium liners require an additional internal rubber liner to improve the wear resistance. A much more economical solution is to use steel liners. An added advantage of using a steel liner is that it allows for use of steel connectors that are cheaper than the titanium connectors used on the Heidrun composite riser joints.

Therefore, it is clear that if composite risers are to be developed to a viable product, they must be used with steel liners and steel connectors. The use of steel liner imposes some complications to the design of composite risers. This project is intended to qualify composite risers with steel liners and connectors.

In order to demonstrate operational confidence in the composite riser with steel liners and connectors, Conoco was successful in obtaining Petrobras approval to run a joint on their P-17 rig. This project is intended to design, manufacture, and test a sub-scale composite riser joint with steel liners and connectors in order to design and manufacture a full size composite riser joint for installation on Petrobras P-17 rig.

The steel liner and end connectors are currently being manufactured at the KOP facility in Houston. The composite structural overwrap will then be applied at the Spencer Composites facility in California.

In conclusion, composites have been developed mainly by the use of well-proven technology and production methods. Composites will be certified according to the design guidelines currently being developed by DNV, and will be commercially available by the end of 2001.

Acknowledgement

Ole Lindefjeld and Jay Murali of Conoco and Egil Martinussen, Harald Wiken, Bjorn Paulshus, and Roy Kristiansen of Kvaerner Oilfield Products contributed to this paper.