Solid streamers demonstrating better operations up-time

Solid streamer technology has entered the marine geophysical market at an important time. The technology is causing a significant reevaluation of some of the accepted approaches to seismic exploration. Sentrytrademark solid streamer technology, which was introduced by Thomson Marconi Sonar in 1996, has now been in commercial service with Western Geophysical for three years. The primary benefits have been:

- Increased operational "up-time" due to damage resistance and high sea-state tolerance

- Improved seismic data quality through lower noise.

Recent falling prices for 3D marine seismic data and the "vessel-stacking" taking place in the industry underscores the difficulties faced by contractors who must deal with high operational costs, large capital outlays, and a wide range of risk factors - weather, equipment failure, and the environment. The now-familiar large 3D multi-streamer survey vessels which provide most of the oil industry's offshore seismic information operate on a very marginal economic basis, with profitability almost impossible at today's current prices.

The oil industry is expecting a lot more for a lot less from the seismic contractors, compared to just 10 years ago. The industry demonstrated that it can survive the pressure, but only the highest productivity methods and equipment will in the future be considered adequate.

The seismic industry spends a large amount on streamer purchase and maintenance. In fact, streamers account for the largest single category of acquisition instrument spending in the geophysical industry. In the mid-1990s, over US$200 million per annum was spent by the geophysical industry on streamer cable sections, in-water electronic modules, and maintenance of these two components. So, it is not surprising that the industry has been looking to increase the effectiveness of that investment.

Background

The direct connection between sonar and marine seismic technology dates back more than 50 years. Marine seismic exploration techniques originated with World War II sonar researchers, who noticed that their attempts to use dynamite explosions as a form of acoustic illumination for submarines were hampered by strongly reflected low frequency signals originating deep in the sub-bottom geology.

The immediate post-war period saw technology transfer from the sonar field into the new industry of geophysical exploration. Today, towed linear acoustic arrays are routinely and extensively used militarily to detect ships and submarines, and commercially for offshore geophysical exploration. In each application, the technology has reached a high level of maturity and refinement.

Until very recently, the arrays used were typically large in diameter (80-90 mm), inflexible, heavy, cumbersome, and, due to their liquid-filled nature, were easily damaged. These characteristics gave them adequate performance, but limited the length or number of streamers that could be simultaneously towed. They also contributed significantly to the high cost of towed array operations (both naval and geophysical).

Seismic streamer design has tended to take a unique path, in which the mechanical and acoustic performance is optimized for lower frequencies (typically 5-200 Hz) and large seismic aperture. Seismic streamers must accommodate apertures up to ten km to enable discrimination between various elastic wave modes generated in the earth. As the signal processing algorithms have evolved and target depths has increased, streamers have grown in length from 1-2 km up to 10 km today.

Military sonar streamers have taken a different path over the last 30 years, with emphasis on medium frequencies (20 Hz to 2 kHz) leading to short (under 1 km), densely spaced hydrophone arrays which are used for accurate target detection using real-time acoustic beam-forming techniques.

Evolution

In the mid-1960s geophysical companies and military users began to use a then-new streamer construction based on a liquid filled hose concept. This construction provided an effective solution to two problems - acoustic noise and buoyancy. The hose, creating a hydraulic waveguide, had the effect of averaging turbulent pressure fluctuations on the outer skin and hence drastically reduced flow noise. The fill fluid could be selected to develop neutral buoyancy, an essential characteristic of a long towed array. This construction has survived essentially unchanged until very recently.

Although such streamers were very effective, they had some major drawbacks. The hydrophones became subject to a form of noise excitation known as a "bulge wave" in which mechanical disturbances generate internal pressure fluctuations, which travel some distance along the hose.

The hydrophone signal becomes potentially much more sensitive to towing vibration than it would be, were it subjected to vibration in isolation. Another problem is that these streamers regularly lose their neutral buoyancy through fluid leakage at jacket tears and pinholes. This also results in saltwater ingress and the eventual breakdown of electrical components. There is also the potential for environmental impact, which can be avoided with solid streamers.

Military streamer R&D

Open water tow-test facility

In the early 1970s, several nations initiated research and development (R&D) into streamer use for naval applications. In Australia, the Defence Science and Technology Organisation (DSTO) began research in the early 1980s, in response to a Royal Australian Navy request. This program had the objectives of providing a robust, long, and small diameter array for surveillance (low speed) applications and culminated in the development and successful demonstration of their (patented) Kariwara solid-filled technology for submarine applications. Kariwara technology was subsequently passed to industry for development, and GEC Marconi Systems (GMS) extended the performance envelope to include higher (tactical) operational speeds.

At the same time, Thomson Sintra Pacific (TSP) initiated the Australian Narama array technology. It was liquid-filled (to meet high-speed performance requirements), robust through its unique construction methodology, and low in unit cost, through its largely automated methods of manufacture.

The Australian Defence Depart ment, wishing to see Kariwara technology fully commercialized, established extensive tow testing facilities based not only upon those previously established by DSTO in Adelaide, but also a comprehensive collection of special purpose mechanical test facilities. It also contained a unique facility for measuring the transmission of vibrational waves through the array structure. These military facilities soon after became a key resource in the development and testing of the solid streamer.

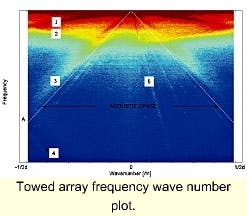

In the investigation of the performance of these first Australian-built operational towed arrays, frequency wave number (FWAN) analysis was utilized for discrimination between noise sources. FWAN enabled a clear discrimination between different acoustic noises:

- Waves of in-water acoustic origin (in the acoustic space)

- Waves traveling in the array (in the boundaries of the acoustic space)

- Waves of lower speed, of mechanical or "bulge wave" origin (outside of the acoustic space).

The use of this form of analysis enabled significant advances to be made in overall array performance, by identifying and addressing major contributors to array self-noise.

Commercial seismic product

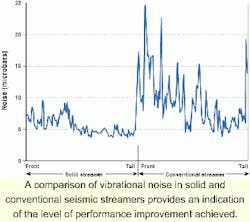

A comparison of vibrational noise in solid and conventional seismic streamers provides an indication of the level of performance improvement achieved.

In 1992, GMS initiated a program to adapt its solid-filled naval array technology to the seismic application. A major advantage of the solid array technology is that it can sustain external damage without rendering the streamer inoperable, as is the case for liquid-filled streamers. Further, such damage can normally be repaired onboard (a liquid-filled configuration must be returned to a depot for repair) resulting in significantly reduced operational downtime.

With sponsorship from Western Geophysical, GMS looked at the less-than-impressive record of prior military array manufacturers' attempts to move into the seismic domain. GMS perceived that their counterparts had attempted to adapt military technology to meet the seismic industry requirements, producing arrays that were high performers if used in the high-speed regime, but not necessarily good performers in the lower speed, and often, high sea-state seismic regime.

Consequently, GMS sought to identify the predominant performance issues for the seismic regime (robustness, adequate acoustic performance in a high vibration environment, and low cost) and to address these specifically with the background of both an R&D approach and knowledge of array manufacturing and testing procedures. The program involved the development of special purpose sensors, and the utilization of the established towed array testing facilities both in Sydney (mechanical handling) and Adelaide (acoustic, vibration, and tow testing).

The application of the experience gained over ten years' work on solid streamers for military applications, plus the development of new lightweight solid materials, resulted in a unique design for a solid seismic streamer.

Using the techniques and facilities developed for the military array programs, which enabled separate assessment of vibrational and acoustic performance characteristics, plus a new test facility developed specifically to characterize the flow-induced noise in seismic streamers, GMS was able to effect a rapid turnaround of the development cycle. It demonstrated a significant improvement on current industry standards of vibrational performance without degradation to acoustic performance.

The mechanical handling requirements for geophysical seismic streamers are more severe, than requirements for military applications. This is because of their greater lengths and because multi-streamer operation requires the host vessels to maintain operating speeds during deployment and recovery operations. The prior military array development and testing experience, and established facilities, were applied to demonstrate that the new design met stringent industry requirements.

Conclusion

A rigorous and intensive study of the requirements of multiple seismic streamer operations led TMS to focus on acoustic performance in the high vibrational environment, together with overall robustness and immunity to superficial damage. That approach has now resulted in the first commercially successful solid-fill seismic streamer technology.

Sentry was first sea-trialed in 1996, and has since proven to operate in sea conditions far more severe than can its conventional counterparts. With some three years of service now accumulated, it has also proven to be less subject to damage, resulting in a much higher operational availability.

Solid streamers will provide a key component of the 3D marine seismic solution in the future, by ensuring that large seismic vessels remain productive for many more days per year than in the past, while providing geophysical customers with superior data quality.