Multi-port flow selector offers production testing alternative

Paul Schafbuch

Chaitanya Shah

Emerson Process Management

Of the many design criteria for floating deepwater offshore production facilities, reducing weight and footprint are among the most important. Since the costs of topsides and hull relate directly to their weight, designers and engineers constantly look for technologies to make offshore platforms more economical to construct with less steel.

Additionally, operators continually examine ways for the facility to require less human intervention and lower operating expenses (opex). When brownfield modifications are necessary to accommodate well additions, subsea tiebacks, or augmented processing capacity, those changes can be costly within the fixed footprint and complexity of piping already in place.

Testing of component flows is a crucial part of offshore production. Regular monitoring and real-time measurement are required for the well's produced fluids including oil, condensate, gas, water, and/or brine. Conventional test methods require a dual system, with one manifold connecting the wells to production and a second connecting the test well to a shared multi-phase meter or separator. This system is often heavy and requires a large footprint. An alternative for production well testing is a compact, stand-alone flow selector with multiple ports.

Conventional well testing

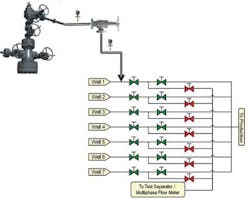

Using a typical production system, wells connect to both a common production manifold and a test manifold. To test a particular well, the line must be isolated from the production manifold by closing a valve and opening another to direct the flow from production to the test facility. Most often, this is a manual operation. All the remaining wells continue to flow through the production manifold as usual. Regardless of test technology, individual well flow must be periodically diverted for volume and composition testing.

A conventional design uses a seven-well, dual-manifold system. This configuration uses 21 isolation and check valves to regulate production flow from seven wells, and to divert flow individually to the test separator and multi-phase flow meter while the other wells remain online. One such offshore dual-manifold skid for conventional well testing procedures has a footprint approximating 36 sq m (387.5 sq ft) and weighs approximately eight tons.

To install this typical manifold quayside requires five days. Its weight can be a factor in the design of a single-lift production module to be installed offshore. The system, with the number of valves required and being subjected to the harsh elements of deepwater service, has an increased number of leak points and opportunities for valve repairs. Experience shows that this typical skid arrangement can require frequent service trips, adding to the facility's opex.

An alternative

A newer, more cost-effective, less complicated, and more efficient solution to well testing is the multi-ported flow selector. The equipment was developed for both onshore and offshore use. In onshore applications, space is not restricted but longer piping runs with multiple valves are costly.

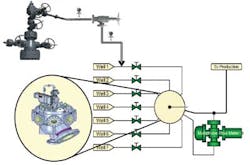

In offshore use, the piping runs are more compact and complex with wells in close proximity, but space and weight are at a premium. The flow selector with its rotating plug allows the selecting and diverting of flow from a single well to a single test unit, flow loop, or testing device. It uses up to seven flowlines through a separate group outlet carrying flows to the production header while simultaneously isolating the single line being tested. Pressure drop across the unit is typically small, with flow streams diverted but not restricted.

An eighth port is used for "parking" the selector when the manifold is in full production. Its configuration depicts the seven line manifold used with only a single check valve needed for each. This cuts the number of isolation valves from 21 to seven, and reduces control points, wiring, and piping requirements. Hookup can normally be done onshore in less than three days, and its lighter weight facilitates modular lifts offshore.

Capital expenditures for the equipment are reduced because of its compact size and weight. The weight of a standard flow selector skid, with seven 3-in., 600-lb ANSI inlets and a 6-in. group port, is approximately five tons, or 40% less than the conventional test skid. Its nominal size, at 12.25 sq m (131.8 sq ft), is slightly more than one-third that of the traditional skid. Engineering firms estimate that installed topsides cost approximately $35,000 to $50,000 per ton. Using that guideline, the weight savings of the unit and additional reductions in necessary deck structural support for the lighter, more compact equipment would be more than the cost of the selector skid.

Whereas the conventional well test skid is often manually operated because of the cost of actuating all valves, the flow selector can be easily and economically automated with a single electric valve actuator to electronically control and monitor the selector's operation. The actuator, with remote monitoring capability, provides an additional dimension by precisely positioning the selected port and retaining it in that position even in the event of a power loss. Built-in diagnostics detect and resolve any operational issues. Operators can issue a remote command to position the diverter plug on the selector system to the desired well either locally or remotely using any of multiple communication protocols. This capability reduces the likelihood of manual valve operating errors in the field. Additionally, the selector avoids unnecessary reservoir flowrate disruptions by inherently diverting flow rather than stopping and re-starting it, as with a manually operated conventional system.

Remote system

To make informed decisions on choke settings, chemical injection, and other criteria, production engineers need to rely on well data more often than that collected monthly. The flow selector can be an integral part of a total centrally monitored automation system for reservoir management and production optimization on each well. With remote monitoring, real-time production rates can be seen as soon as a well is switched to test. The remote well testing solution using the flow selector device can be incorporated with an electronic flow meter that replaces conventional test separators, measuring the multiple flow constituents without the need for separation. This technology reduces footprint to approximately 1 sq ft and lowers test duration by 80% or more. Real-time reporting allows the production engineers to make necessary decisions. This capability is particularly useful on marginal field wells where human intervention would otherwise be needed onsite for testing and optimizing flow conditions. Of course, this can be costly and make the facility less viable.

Conclusion

The use of multi-ported flow selectors has proven to be less expensive and more effective on remote deepwater production facilities than its conventional counterparts. The selectors provide capex benefits with a smaller footprint and considerably less weight. With only one-third of the valves necessary in the system (compared to a conventional system), maintenance is reduced, which in turn reduces opex. On unmanned production platforms, well testing can be done remotely with accurate valve actuation and multi-phase metering that provides engineers with real-time flow characterization rather than the need for periodic human intervention to conduct well tests and make on-site adjustments. With these improvements, wells can be optimally produced, even in marginal fields.

The authors

Paul Schafbuch is vice president, engineered products for the valve automation unit of Emerson and is located in Houston. Dr. Schafbuch has graduate degrees from Stanford and Iowa State universities and 30 years of experience in valves, actuators and process control.

Chaitanya Shah is business development manager at Emerson Process Management, in Dubai, UAE. Shah is a mechanical engineering graduate from Shivaji University (India) and has more than 11 years experience in the oil and gas industry with valves, actuator, fired heaters, process boilers, and related process equipment.