A new generation deepwater field development system

Richard D'Souza

David Barton

Halliburton KBR

Steve Hatton

2H Offshore Engineering

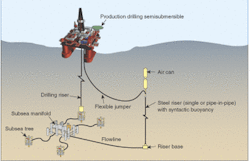

Production drilling (PD) semi platforms with subsea trees have been selected in preference to dry tree platforms for several large deepwater developments in the North Sea, Brazil, and the Gulf of Mexico. In ultra-deepwater, a conventional PD semi with subsea wells is a proven and comm-ercially attractive alternative to a conventional PD Spar platform with surface trees. It also provides greater flexibility to accommodate reservoir uncertainty and lower technical, cost, and schedule risk.

The value of using a systems engineering approach to identify "high-impact" emerging technologies has been demonstrated. These approaches span a broad spectrum of disciplines and enable the creation of a next generation PD semi platform field development system. This system will have the potential to significantly reduce capital expenditures in deep and ultradeepwater developments. Potential capex reductions for this new generation PD semi system are calibrated against a conventional PD semisubmersible (extrapolation of current practice) in 3,000 m of water. All emerging technologies included are, or will be, commercially available within a three-year horizon.

Systems engineering approach

Full field development economics require that a field development system be assessed in its totality over its life cycle, including capex, drilling expenditures (drillex), operations expenditures (opex), cycle time (discovery to peak production), production availability, and reservoir management. A systematic process is used to assess all current and emerging technologies for each subsystem of the PD semi field development system, from reservoir to export pipelines. From this process, several high impact enhancing or enabling technologies are identified for inclusion in the next generation PD semi. A primary selection criteria is that the technology be "maturable" within three years.

Field development is preceded by exploratory and appraisal drilling and occasionally completion of production wells. The high cost and technical challenges of drilling deepwater, deep zone wells has long been an industry concern. Consequently significant intellectual capital and development funding has been directed toward enabling and cost reducing technologies in these areas.

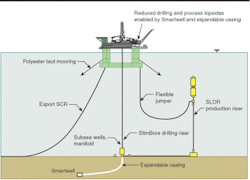

A schematic of the new generation production drilling semi field development system.

This effort has resulted in many breakthroughs. Those that will both reduce drillex and have a direct beneficial impact on the platform capex are dual activity drilling, dual gradient drilling, slim-bore drilling, high pressure drilling risers with surface BOPs, expandable casing, and free standing drilling risers. Each will provide benefits such as lower day rates, reduced drilling time, reduced drilling consumables, and higher well rates.

A further assessment of these technologies concluded that the expandable casing technology would provide the biggest capex "bang for the buck" because it enables use of a significantly smaller marine drilling riser and BOP. This in turns leads to significant drilling equipment cost and topside drilling payload reductions, resulting in a smaller platform. The benefits increase with water depth.

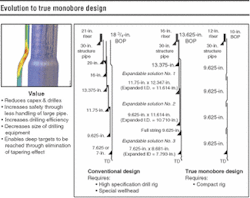

Evolution to a true monobore design will enable use of a single 9 5/8-in. casing size, resulting in a continuous inner diameter from target depth to mudline wellhead.

Downhole completion technologies have been leading the way to improved deepwater economics by improving reservoir management, per well flow rates, ultimate recovery, and reduced well intervention. Short listed technologies include multi-lateral wells, downhole separation, and intelligent or smart well completions. Of these, the SmartWell completion was picked because of its maturity and its potential to significantly reduce platform topside process payload by controlling the amount of produced water and gas to be treated on the platform.

Water depth drives the cost of station-keeping and production/export riser systems. Conventional practice is to use wire-chain spread moorings with suction piles and steel catenary risers. The increasing weight of these systems adversely impacts platform size and installation costs. The Deepstar-led System and Value Engineering initiative to identify high value enabling and enhancing technologies for floating systems in ultradeepwater concluded that polyester moorings and offset free-standing production risers had the greatest potential to reduce cost. These technologies reduce not only the cost of the system, but also of the production platform that supports them.

Completions

Advances in well completion technology utilizing various combinations of downhole tools and sensors enable operators to control and monitor flow from multiple producing intervals in the well in real time, commonly referred to as smart or intelligent wells. Well monitoring functions include sensors to measure temperature, pressure, and flow rates. Control functions include remote-operated sliding sleeves to control flow quickly in response to changing downhole conditions. The combination of real time information on well performance and the ability to control flow from reservoir to well bore has resulted in dramatic improvements in well flow rates and total recovery, key elements in improving deepwater field development economics.

Up to 25% reduction in weight and cost of topside process train is achievable by reducing the percentage of produced water cut and gas breakthrough into the well bore. Producing the reservoir more efficiently from fewer production wells reduces Drillex. Opex is reduced by significantly reducing the need for downhole intervention, normally required with conventional wells to measure downhole conditions or to shut off depleted zones. These completions have been installed and are functioning in several deepwater GoM and North Sea wells.

Expandable casing

Simply stated, expandable casing technology enables the radial expansion of a string of casing with special downhole tools by permanent deformation of the pipe through a cold working process. Originally devised as a means of in situ repair of damaged or corroded casing and pipelines, the technology is being increasingly utilized as a means of achieving step-change reductions in drilling cost by reducing the size, number of casing strings, and time required to reach targeted depths relative to a conventional well construction program.

For deepwater well construction, a conventional design would typically require five or more varying diameter casing strings with an 18 3/4-in. subsea BOP and a 21-in. low-pressure marine riser. Nested expandable solutions currently available enable use of a slimmer bore 13 5/8-in. subsea BOP/16-in. marine riser. Evolution to a true monobore design, currently in final engineering, will enable use of a single 9 5/8-in. casing size, resulting in a continuous inner diameter from target depth to mudline wellhead. This in turn will enable a 10-in. BOP/12-in. marine riser system. The direct consequence of expandable casing technology is a dramatic improvement in drilling efficiency, together with a reduction in cost of drilling consumables (mainly casing, cement, and mud) relative to conventional wells.

Cost benefit

The consequential cost benefit to the PD semi that will drill local development wells is equally dramatic. A major driver of size and capex of a deepwater PD semi is the weight and footprint of drilling riser and BOP stowed on the platform. A reduction in size from an 18 3/4-in. BOP/21-in. riser to a 10-in. BOP/12-in. riser in 10,000 ft of water will result in a 40% reduction in weight and cost of the riser/BOP equipment alone.

Every ton of topside weight reduction yields about $10,000 savings in platform cost. Additional platform capex savings resulting from monobore well construction are:

- Reduction in casing rack storage area and weight and associated handling equipment

- Reduction in bulk and liquid mud and cement storage volumes

- Reductions in riser tensioning, derrick hook load, mud return system, mud pumping requirements, and associated power generation

- The lighter riser/BOP system is considerably easier, faster and safer to deploy and retrieve than the conventional riser/BOP, which could take several days in 3,000 m of water.

The Single Line Offset Riser is a free-standing riser in either a single or pipe-in-pipe configuration using steel pipe.

Further improvements in drilling efficiency are achievable via the deployment of a high-pressure marine riser and surface BOP. This operation has been successfully used to reduce drilling costs in Southeast Asia from semi MODUs, and it will debut shortly in the GoM.

The use of slim-bore drilling has been quite extensive. Petrobras has successfully drilled over 41 slender wells in the Campos basin alone and achieved an average improvement of 17% drilling efficiency over conventional wells. Expandable solutions have been proven in several successful installations and field tests. As of January 2002, approximately 50 expandable casing systems have been installed for 15 different operators, some in ultradeepwater wells.

Production riser system

For deep and ultra deepwater fields developed by a PD semi, subsea trees are located beneath the platform to enable access for drilling and workover. Several trees are manifolded on the seabed, and the commingled flow is routed to the platform via production risers. Current trends on Spars and TLPs favor the use of steel catenary risers (SCRs) for export service because of their apparent simplicity and low installed cost. However, for semisubmersibles, SCRs are more complex due to the higher vessel motions and the need for insulation for production service. Additionally, the number of flowlines often required can result in a complex field layout.

This complexity increases with water depth and can impact the cost-effectiveness of such systems. A simpler, more attractive production riser alternative to the SCR is proposed.

The single line offset riser (SLOR) is a free-standing riser in either a single or pipe-in-pipe configuration using steel pipe. It is offset a short distance from the manifold and connected to the vessel using a short section of flexible pipe. It is based on proven wellhead and drilling technology and, in many respects, is similar to a Spar top-tensioned riser, but without the complex vessel interface.

Mooring system

Multi-leg wire-chain spread moorings with drag or suction pile anchors have long been the workhorse for permanently moored production platforms. Although wire-chain systems are technically viable for mooring large PD semis in the ultradeep, the efficiency degrades and costs escalate in increasing water depths.

In the early 1990s, the industry recognized that significant cost-reductions and performance improvements in the mooring systems were attainable by substituting lightweight synthetic fiber rope for wire rope. Of the many types of synthetic fibers investigated, parallel lay polyester fiber ropes emerged as the front runner because of its lightweight, low modulus, fatigue endurance, and relatively low cost/ton of break strength.

The major concern expressed by a majority of GoM operators is lack of "long term" experience, particularly potential degradation due to low cycle fatigue, marine growth, undetected damage during installation, and the lack of a suitable inspection and discard criteria.

The main benefit of polyester rope moorings is the potential for significant reduction in installed cost for a deepwater PD semi in the GoM versus a wire rope mooring. There appears to be general consensus that the application of polyester rope for mooring floating production systems in the GoM is less than three years away.

Topside process system

The operating weight (equipment, bulk, support steel, liquids) of a conventional topside facility to process 150,000 b/d with a 2,000 gas-to-oil ratio is substantial and requires a large deck area. A 10-20% reduction in operating weight and footprint will have significant impact on size and capex of the floating platform. An analysis of the apportioning of the weight reveals that about 50% of the weight is contained in about 15% of the process and utility systems. There is limited opportunity to reduce weight and size in the remaining 85% of the equipment.

The systems with greatest opportunity for weight reduction are separators, water treatment, water injection, gas compression, power generation, and living quarters. Smart well completions enable the continuous monitoring and control of produced water and gas breakthrough. This in turn enables potentially large reduction in size of separators, water treatment, water injections, and gas compression systems versus conventional completions and smaller reductions in power generation system and living quarters resulting from reduced manning.

GoM case study

A case study for a PD semi based field development in 3,000 m is used as a basis to quantify capex savings achievable by integrating the high impact technologies described into a next generation PD semi versus a conventional PD semi.

A PD semi is sized with conventional well construction and completions (18 3/4-in. BOP with 21-in. marine riser), SCR production and export risers, and wire-chain moorings with suction piles. A next generation PD semi is then sized with SmartWell completions, monobore well construction utilizing expandable casing, SLOR producion risers, and polyester moorings with vertically loaded anchors. In each case, a state-of-the-art Gotavarken Arendal four column, ring-pontoon hull with integrated box deck is the chosen hull configuration. The technologies incorporated into the next generation PD semi allow the deck size to be reduced by approximately one-third compared to a conventional PD semi.

A comparison of major components with variable drilling deck loads indicates a 50% savings in weight with the monobore system. Besides significant reduction in BOP/riser weight, additional reductions in casing, liquid mud, bulk mud, and cement are realized as a result of the monobore well and slim bore drilling riser.

Additionally, a 3,000-ton (20%) reduction in process facility operating load from these completions is realized. A similar reduction in drilling payload is achieved by incorporating monobore drilling and well construction technology. The combined mooring and riser vertical loads on the platform are reduced by 6,000 tons (50%) by substituting SLOR production risers and polyester moorings. The hull designed for these reduced loads has about 6,000 tons (20%) less hull steel and outfit weight.

A savings of $137 million is indicated, representing about a 20% capex reduction relative to a conventional PD semi. A three month schedule savings to first oil is also achievable because of the reduced size and complexity of hull and topsides and the decoupling of production riser and hull designs.

Acknowledgements

The authors would like to thank Roy Burkett, Dave Adams, Duncan Scott, Richard Haut, Mike Mattern, Bill Greiner, Chuck Kerr, Catherine Marrs, and Darlene Withrow for their input and support in preparing this paper.