Ventilation Heat Exchange - Compact titanium heat exchanger more durable and energy-efficient

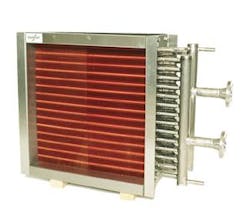

A titanium heat exchanger introduced by Coiltech for the offshore sector features titanium tubes with fins made from either copper or tin-plated copper, all contained in a stainless steel housing.

Titanium provides a more cost-effective solution in the corrosive environment found on an offshore platform, says Ralf Sandman, Coiltech's manager, marketing and sales, ventilation. As the alloy is almost immune to the corrosive action of seawater at normal temperatures and to salinity, it allows seawater to be used as a coolant in the heat exchanger.

This opens the way to numerous benefits. "For instance," Sandman says, "the stronger resistance to corrosion helps extend our product's lifespan. This in turn makes maintenance cheaper, as the maintenance intervals are longer than is the case on conventional systems. It also allows us to achieve a technically simpler, lower cost and less space-consuming solution, which in addition is easier to operate."

Copper tubing is often protected from corrosion by establishing a two-circuit system in which the coils are fed with fresh water instead of salt water. Compared with the titanium heat exchanger, however, such a system will weigh more, and have a larger footprint and a greater energy requirement, all negative factors in an offshore context. A two-circuit system is also technically more complicated, which again means increased maintenance.

Compared with alternative tubing materials such as copper, titanium offers a much longer working life. Copper tubed coils normally have to be changed out every five to seven years, but the first titanium heat exchangers installed offshore – in the 1990s – are all still thought to be in operation, Sandman says. Over the lifetime of an offshore installation, therefore, maintenance requirements of a titanium heat exchanger will be well below those of units made from copper or stainless steel.

He adds: "These minus points do not apply in the case of our copper fins, as these are only in contact with air, unlike the tubes, which have contact with seawater. It is possible to manufacture 100% titanium coils, but the heat transfer capability of titanium fins is inferior. This means we would end up with bigger and more expensive coils, with lower efficiency. There is limited demand for these type of coils in very demanding chemical industries, where the ambient air is also extremely corrosive, but not as yet in the offshore sector."

Returning to the heat exchanger tubes, another factor in titanium's favor is that it is lighter than other materials that also have good anti-corrosion qualities. A Coiltech titanium heat exchanger offers a weight saving of 10-15% over an all-stainless steel unit, according to Sandman.

The titanium heat exchanger launched by Coiltech is claimed to be a more cost-effective solution in the corrosive offshore environment.

null

A further advantage of the Coiltech design is that it incorporates a collector pipe that makes the unit more compact and more suited for installation in an air-handling ventilation unit. The collector pipe replaces a flanged cover, which has proved difficult to keep tight on competing designs.

"We ourselves are still manufacturing coils with a 'cover' instead of a collecting pipe, in titanium and other materials," Sandman says. "However, these coils tend to be tailor-made for bigger, one-piece deliveries. They are not currently competitive for ventilation applications. At the moment, as far as we know, we are one of only three companies in northern Europe manufacturing titanium coils with collecting pipes."

Traditionally, aluminum fins have been used in ventilation coils. The humid atmosphere in offshore environments could encourage microbial growth on these fins, but this can be avoided by using copper or tin-plated copper.

Coiltech's titanium heat exchangers are currently supplied in standard sizes ranging from a width of 0.20-0.30 m and a height of 0.2-2.4m. For a maximum front area of 7.2 sq m, the air flow capacity is up to 40 cu m/s.

Coiltech is a leading supplier of heat exchangers and air handling equipment, supplying 50,000 heat exchanger coils a year. Every order is tailor-made to the customer's specification, using the company's own calculation program to determine the optimal dimensions. Depending on the material, delivery times of one to six weeks are normal.

For more information contact Ralf Sandman, Coiltech. Tel: +46 121 191 53, Fax: +46 121 148 43, [email protected], www.coiltech.com