Halliburton develops packer to address gas/fluid migration

Offshore staff

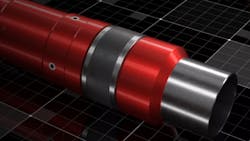

HOUSTON — Halliburton has released its Obex EcoLock, a compression-set packer designed to help prevent sustained casing pressure.

The packer is said to offer a cost-effective mechanical barrier to mitigate low-pressure gas or fluid migration and provides isolation assurance. It is a further development of the company’s gas-tight, V0-rated Obex GasLock packer design.

Matt Lang, vice president of Cementing, said the development offers an “economic alternative to inflatable and expandable packers to deliver isolation assurance independent of losses or circulation pressures," and “enables us to deliver a suite of API/ISO validated casing annular barriers to keep pressure away from the surface and support cemented barrier.”

The tool operates by setting the packer elements with a seated free fall plug and applied internal casing pressure. An internal continuous ratchet mechanism ensures the packer stays compressed from the initiation of the setting until it is fully set.

Backup shoes keep the packer elements energized to prevent low-pressure gas or fluid from migrating against the previous casing string, resulting in zero weak points in the packoff, Halliburton said, mitigating sustained casing pressure and ensuring an effective seal for the life of the well.

A drive-pin setting system is said to eliminate potential leak paths from the setting operation, and the assembly process does not rely on welding. Both these features are said to remove the risks associated with fluid losses in the well, which could compromise holding pressure and prevent the packer from fully setting.

When the drive-pins shear at the end of the packer stroke, this is an indication that the setting system has delivered the required setting force to the elements and that the packer is set.

07.25.2023