Amarinth overhauls offshore UAE pumps for extended service

Offshore staff

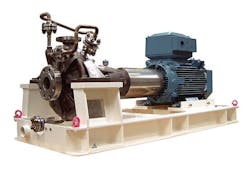

WOODBRIDGE, UK – Amarinth has refurbished offshore sodium hypochlorite dosing pumps for ADNOC that were originally manufactured in titanium alloy.

In 2016, the company delivered the pumps for sodium hypochlorite dosing on ADNOC’s Umm Lulu platform, 30 km (18.6 mi) north-west of Abu Dhabi.

According to Amarinth, sodium hypochlorite is corrosive and this ruled out use of traditional super-duplex materials. So the company instead supplied the existing pumps with titanium alloy for all wetted parts after ADNOC decided they were in need of refurbishment.

The pumps are critical to production and refurbishment had to be aligned with a shutdown schedule.

Amarinth’s UAE facility completed the strip and assessment report within five days and proposed two refurbishment projects. The first would involve a full rebuild, test and warranty of the first pump replacing all the titanium components including impeller, shaft, bearing brackets and mechanical seals.

To meet the eight-week deadline, the company prioritized ordering of the titanium components using its supply chain to ensure all parts would be manufactured and shipped to the UAE on time.

The second project would entail similar work on the other two backup pumps to be completed in a 24-week schedule.

Amarinth was able to complete the refurbishment work as scheduled, delivering fully tested and warrantied pumps so that ADNOC could continue production until its next scheduled capital assessment.

04.22.2022