FRONTIER EXPLORATION: Exploration drilling resuming on old Turkmenistan platforms

Development drilling has resumed on Turkmenistan's sole producing offshore concession, with western contractors now at the helm. This is also the first concerted effort to exploit the Cheleken Contract Area's full potential since its two fields came onstream in the 1970s.

Deutag is drilling the wells on behalf of operator Dragon Oil Turkmenistan, using a land rig deployed from a platform on the Lam Field in 25 meters of water. The first of three back-to-back wells was spudded early this year. Lam 22-101 will likely take 90 days to drill and complete. If results of this and the subsequent wells meet expectations, Dragon may opt for a further three wells later this year to expand production.

Lam, Zhdanov fields

Currently, 17 wells drilled from five other platforms on the Lam and Zhdanov fields produce 7,500 b/d of oil and small quantities of associated gas, which are piped a short distance to the shoreline of the Cheleken peninsula. Over the years, 63 platforms were installed by the former Soviet operators, but the facilities fell into decline as the Soviet Union dissolved.

In 1993, the Dutch company LEA entered into a joint venture with Turkmenistan in an attempt to revive production, providing $90 million dollars for infrastructure upgrades. Two years later, however, output had tumbled further to little more than 4,500 b/d.

Nevertheless, Block II (as it was then known) offered tantalizing potential, with an estimated 384 million bbl of oil and 2.67 tcf of gas remaining. Dragon, which was a small company listed in Dublin and London, took a risk by buying 60% of LEA. The new operator embarked on an intensive rationalization/workover program. The number of working platforms was reduced to 12 by 1998 and halved again by 2000. Well rehabilitation was equally laborious, with many in serious disrepair.

The Lam Field's stacked, over-pressured reservoirs are of mid-Pliocene age. On Zhdanov, hydrocarbons are present in numerous horizons within the early to mid-Pliocene. The low sulfur, 39 degree API oil is piped to an oil export terminal in Aladja on the peninsula, from where it is shipped south to Neka on Iran's Caspian coast. Under a swap arrangement, Dragon lifts equivalent amounts of crude from Kharg Island. Contractual terms were recently re-negotiated in Dragon's favor, further aiding the current project's economics. Associated gas produced from the two fields is consumed by the town of Cheleken and a local carbon black plant. A gas flaring system was also installed nearby in 1998, but this is currently not in service.

Re-negotiations

Remedial measures include altered choke settings, chemicals injection, and hot oiling operations. Dragon managed to lift oil production beyond 7,000 b/d by late 1997. Then, the company ran into financial problems of its own, which were exacerbated by the oil price drop. Order was restored in 1999 when Emirates National Oil Company (ENOC) was brought onboard as the majority shareholder. ENOC is a group of 16 companies drawn largely from the refining and marketing sector, which agreed to provide funding for further development of Block II.

In 1999, the company negotiated a new production sharing agreement (PSA) with the Turkmen government to replace its existing joint venture agreement. In the interim, production from Block II was curtailed to a care and maintenance basis. Although the new accord was signed in November 1999, it did not become effective until May 2000. Entering into the PSA was also a requirement of the $60 million loan, secured through the European Bank for Reconstruction and Development. This money would be needed for the new wells and facilities for the re-named Cheleken Contract Area (CCA).

Land rig offshore

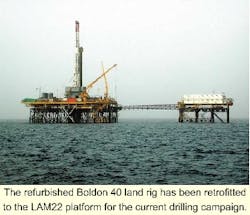

To pursue its current program, Dragon purchased a Boldon 40 land rig through its subsidiary, D&M Drilling. This was refurbished in Great Yarmouth, UK, for subsequent service on the LAM 22 production platform; it arrived at the Turkmenbashi supply base in September 1999. Simultaneously on the northwest coast of the Caspian, the NCGS yard in Astrakhan was building a new deck, additional piles, and bracing for the same platform, as well as an accommodation platform to house up to 80 drilling/production personnel.

Coiled tubing intervention had been planned to lift production from the other platforms, but was eventually cancelled due to perceived risks associated with the reservoirs. Instead, Baker Hughes undertook wireline intervention on four wells, boosting incremental production by over 1,600 b/d. This effort hoisted CCA production last June to 7,500 b/d.

New drilling

The first new well, LAM 22-101, was due to be spudded the following month. It had to be postponed, however, to September 2000, following a delay in the construction schedule.

Further problems ensued due to a combination of bad weather and damage to the rig mast, which had to be rectified. However, the delays had a beneficial effect, Dragon claims, in that they:

- Enabled the rig to be fully commissioned at the supply base

- Avoided interruptions to the drilling schedule, as the accommodation platform could then be installed before the campaign started

- Allowed more efficient use of crane barges during installation of the facilities.

LAM 22-101 was finally spudded on January 2 this year, targeting "Red Series" horizons III-VIII, which comprise the Lam Field's chief producing intervals. The well is being drilled as a short step-out towards the producing LAM75 platform. Dragon anticipated encountering oil 2,000 meters to the proposed total depth of 4,300 meters. Weather was not expected to interfere unduly with the operation; this part of the Caspian does not freeze over, despite occasional sub-zero temperatures.

Target 25,000 b/d

Assuming that this and the subsequent development/appraisal wells are successful, production could easily be accommodated through the LAM22 platform, which has throughput capacity of 25,000 b/d. A new 10-in. flowline will be installed later this year to pipe some of the produced fluids to shore. In time, Dragon may consider adding further platforms or refurbishing other existing installations.

The CCA program is being managed by a technical team now based in Dubai, led by CEO Ian Baron (ex-Conoco). Personnel include geologists, geophysicists, reservoir and production engineers, and legal and logistics specialists.

According to Baron, they have "completed a range of technical studies essential to the development of the fields. I expect the outcome of the drilling program to be a material increase in Dragon's oil output, which will have consequent positive implications for the company's future cash flow and earnings potential."