PC-based software provides asset management for smart instruments with fieldbus capabilities

Eric Olson • ABB Instrumentation

Offshore platforms are integrating smart instruments into their process automation solutions via fieldbus technologies such as Hart, Foundation, and Profibus. Adding configuration, commissioning, and asset management capabilities to these networks offers the possibility of improving productivity and maintenance while maximizing field instrument availability. Foundation fieldbus and Profibus networks are commonly used in the Americas and Europe; Hart networks are installed worldwide.

For those companies that want to exploit, or experiment with the capabilities of these smart field instruments and fieldbus networks on a small scale, ABB offers asset management software for stand-alone Windows-based desktop PCs and notebooks. The software can work with up to 500 field instruments, depending on the fieldbus. Assets may include field instruments used as transmitters for flow, temperature, pressure, and level; analyzers; actuators; and positioners. Using a single application across multiple instrument vendor products reduces inventory, training, and configuration time.

Offshore platform operators can take advantage of their untapped Hart capabilities of existing instruments by monitoring them to improve operation and duration. For new projects, engineering and maintenance personnel can use the software to configure field instruments (online or offline), set their parameter functions, and monitor and tune them online. The product can also aid in sending diagnostic alerts for managing calibration and processing work orders.

For expanding to larger networks, offshore platforms can migrate up to ABB’s 800xA system.

Configuring, commissioning

Users can configure field instruments both offline and online. The former method offers a controlled environment for set-up. It allows users to establish a baseline for comparison with future modifications. Configuring online in the field improves productivity since the instrument does not need to be removed for work. The plant remains in operation while users make changes.

The software includes integrated management tools for each of the three fieldbus types to aid configuration. These tools support engineers throughout the planning phase of a project. Engineers can select field instruments from a comprehensive library of equipment.

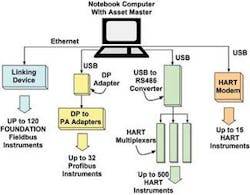

Block diagram illustrates the connections for the three fieldbus types: Hart, Profibus, and Foundation. The actual number of instruments that may be connected to a fieldbus type depends on cable length, type and number of physical drops, and hazardous area location.

Once engineers select the instrument, they can download digital files specific to the instrument and fieldbus types from the ABB web site. The downloaded files include intuitive graphical user interfaces that help simplify set-up and configuration. Downloadable files reduce the effort in maintaining the software while incorporating the most up-to-date information on each instrument.

When configuration is complete, additional management tools support commissioning and installation of the fieldbus networks and instruments. After initialization of the network, users add all the instrument configurations. The system automatically generates bus timing and schedules, while instrument parameters can be displayed and individually modified online.

Diagnostics, remote monitoring

During plant operation, the software can identify and analyze abnormal situations. It alerts the user of degrading performance. Detailed status information available to the user cites the probable causes for alarms and suggests corrective actions. The basic product offering includes support for ten asset monitors, with the option to add more in increments of ten.

A key capability of the software for offshore operations is its ability to alert offsite personnel of developing problems via e-mail, pager, or cell phone. Unanswered notifications can trigger a message to backup personnel. The reported fault can be automatically sent to a computerized maintenance management system (CMMS) to initiate work orders. Users can remotely monitor the status of the work orders on the internet. This way they can troubleshoot problems remotely, saving time-consuming trips to the offshore platform. Quicker response to reported problems can reduce or eliminate process upsets and downtime, resulting in increased productivity.

Optionally, the software can initiate a report upon notification of the need for calibrating a device. The system can track the completion of subsequent events performed in follow-up to the calibration request. It becomes a single source for an instrument’s audit trail, including calibration. By having one source for all audit trail information, users can more quickly analyze the information to verify the status of instruments. Another option fully integrates SAP/PM and Maximo CMMS software with the system.

Asset Master software takes advantage of the power of industry-standard fieldbuses and intelligent field devices. Installed on a desktop PC or notebook, it offers the opportunity for offshore platforms to significantly improve engineering efficiency, reduce time for repair, and optimize plant availability and performance.