FIELD DEVELOPMENT ECONOMICS: Producer's guide to selecting a minimum facility platform

Pat O'Connor

BP

Bob Robinson

Granherne

Over the last 10 years, there has been a high level of activity by design companies, mainly in the Gulf of Mexico, on the development of minimum facilities characterized by fast-track, low-fabrication-cost solutions. More recently, there has been a flurry of activity coming out of the North Sea and remote areas such as the Far East, West Africa, and South America, driven by alternative installation and re-use considerations.

In each region, differences in concepts are driven by regulatory requirements, intervention, operations, maintenance philosophies, and infrastructure drivers, and not by differences in engineering practice. No region offers a superior design. Breakthroughs are achieved by capturing technologies and experience worldwide to deliver an appropriate concept, but can lead to a large number of options to be considered. To manage this, a system that groups similar concepts together, within credible ranges of application, with defined pros and cons, is required.

This article describes recent work by the BP and Granherne as part of a web based concept-screening tool to guide BP asset groups in the selection of minimum facility platforms. The tool provides a classification matrix of minimum facilities covering the full range of development concepts. The asset group can then rank and screen key design drivers based on reservoir constraints, operations practice, infrastructure, and site specific information to reduce the options to a ranked set of preferred solutions for their development.

Why classify?

The choice of minimum structures is extensive, with over 135 designs available from engineering contractors from around the world. From the previous review of minimum structures (Offshore Magazine, January 1999), there has been a 30% increase of new solutions in the global market place.

These new generation concepts tend to use alternative installation strategies or are re-usable and have been developed in regions like the North Sea or remote areas such as West Africa, South America, or the Far East, where lift vessels are either expensive or have high mobilization/de-mobilization costs. In essence, a reversal of roles has begun, where second generation re-usable concepts developed for these applications could feedback into the Gulf of Mexico where piled structures still tend to be used.

BP has set out to rationalize the selection process to classify the concepts into more manageable subsets, which allows a comparative analysis from the global database of solutions for a particular development. The use of a classification approach has several advantages:

- Allows the reduction of over 135 designs to be reduced to a subset of 30, which can be more rapidly and effectively screened

- Allows market competition to be maintained after concept selection, as there are usually a number of turnkey contractors who can offer designs within each classification

- Allows the identification of best global practice and opportunities for technology combinations and experience to define the optimum solution(s) for particular development

- Identifies gaps in the technology base that may provide opportunities for the development of new concepts.

Structure classification

The new generation of minimum facility solutions requires that the original structural classification developed for BP in 1996 needs to be revisited and expanded to allow for alternative installation techniques. Figure 1 shows the wide range of installation strategies that can now be applied to minimum facility concepts. These include, everything from self-installing solutions, barge-assisted and jackup installation to lift boat and derrick barge installations.

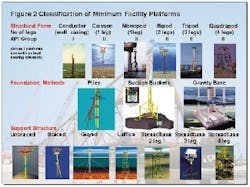

This breadth of installation method has been achieved through the adoption of alternative foundation solutions, from surface gravity base foundations to near-surface suction piles, to deep piled or drilled/driven solutions. While these foundation forms have a proven track record, they still need to be evaluated on a site-specific basis. Figure 2 shows a new classification of minimum structures that can be broken down into three broad categories, identified as:

- Structural form: Number of conductor or leg elements, usually driven by the number of wells and facility robustness considerations.

- Foundation concept: Piled versus suction piles or gravity base.

- Support structure: Unbraced to spread-base concepts which allow structural strengthening as water depth increases.

In the new classification, the definition of support structures has been revisited to identify more clearly the difference between unbraced, braced, traditional lattice tower structures, and spread-base solutions. Braced concepts are identified as those solutions, that post-install a support structure around a pre-installed conductor or caisson.

"Hour glass" or spread-base solutions give significant structural efficiencies over lattice towers by minimizing environmental load and foundation load. With the spread-base structural form, the sub-structure braces out to support the deck above the water, narrows down, and can hide appurtenances within legs in the splash-zone before bracing back out to provide efficient foundations at the seabed. This structural form is more flexible than a lattice tower, but the dynamic response needs to be carefully assessed.

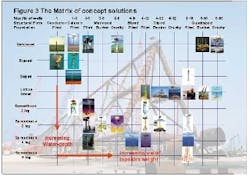

Using this new classification, all the known forms of minimum facility can be identified as shown in the library of minimum facility concepts in Figure 3. All the existing minimum facility concepts identified fall into this matrix, often with several companies producing solutions that fit into the same classification. In other instances, there are gaps in the matrix where solutions have not been developed, mostly because they are not considered structurally efficient. However, future concepts not yet identified may lie within this matrix or may lie beyond it with as yet unidentified forms and foundations.

Regional variations

The revised classification has been tested against minimum facilities around the world to ensure that the classification is truly global. What is of interest is that each region shows specific trends, usually related to infrastructure considerations, which drive the concept selection to particular solution sets.

- In the US Gulf, a combination of low well count, fast track execution, availability of low cost lift boats, and low weather downtime favor use of solutions that minimize fabrication and use offshore construction techniques such as the braced and guyed caisson concepts.

- In West Africa, South America, the Far East, and offshore Australia, remote areas with very limited infrastructure and high installation vessel mobilization costs, asset teams tend to select solutions that maximize synergies with other marine equipment, such as the use of pipelay vessels and jackups to install facilities. These include the use of gravity base and suction pile (bucket) solutions, which can be self-installed or barge installed.

- In Northern Europe, the combination of higher well counts, limited availability of high cost derrick barges, and high weather downtime causes asset groups to favor use of monopod and spread base structures. These structures minimize weight and offshore construction costs, and the suction piles and gravity foundations allow use of alternative installation strategies.

- In Arctic environments, such as the Beaufort Sea, Gulf of Alaska, and the former Soviet Union, monolithic solutions tend to be selected because of their superior tolerance to ice loading.

- In landlocked areas, such as the Caspian Sea, larger launched solutions that can support dedicated drilling packages tend to be adopted due to the lack of drilling and heavy lift vessel infrastructure.

- In deeper water applications, in the Gulf of Mexico and West Africa, the design depth of minimum facility platforms has been increased to 1,000 ft through use of spread-base eight-leg launched "rocket" jackets or guyed towers. However, the deck capacity of these structures has to be sufficient to carry the drilling derrick and support packages.

Concept selection

For each concept, a criterion of 15 factors has been developed, which can be used to assess the appropriateness of each concept for a particular application. These factors include:

- Well capacity: number of wells required, including sparing philosophy

- Operational flexibility: well intervention and future equipment philosophy

- Water depth limits: field-specific water depth

- Deckload capacity: deck weight to be supported

- Wave resistance: field-specific storm and fatigue environment

- Ice resistance: field-specific ice load environment

- Earthquake resistance: field-specific earthquake environment

- Boat impact risk: field-specific boat risk and asset protection philosophy

- Robustness: reserve strength capacity and damage tolerance from asset protection philosophy

- Workforce confidence: evaluation of willingness of workforce to accept concept

- Installation flexibility: competition assessment for installation

- Reusability: requirement to reduce abandonment costs and capture future value (serial development)

- Ease of construction: suitability to local fabrication or out of region fabrication

- Track record: project view of technology risk based on track record

- Cost effectiveness: project view of life cycle cost effectiveness.

Each concept type is graded for each criterion into one of five categories based on an assessment or operations experience of that concept type. The selection process requires working with the asset group to rank each of the 15 criteria in order of importance for their development drivers. Then for each criterion, a filter can be set based on grade (minimum level of performance) considered acceptable. Applying the filter to each criterion in order of importance allows short-listing of concepts for further development and provides an audit trail on the selection process. The resulting shortlist can then be developed to a higher level of detail to deliver the most appropriate best practice for that particular development.

Simplifying the selection of the optimum facility concept from a sea of over 135 designs is made possible by a reduction process based on a simple classification of concepts and by use of ranked selection criteria with agreed minimum acceptable performance criteria. The result is a rapid screening approach that can be field specific and yet deliver the best global practice for a particular NUI development anywhere in the world.

Authors

Pat O'Connor is with BP's Houston Upstream Technology Group. He began his career as a bridge designer for British Rail, but has spent the last 24 years in the oil and gas industry. He worked in the North Sea with engineering contracts, and later joined Amoco, managing such projects as the Davy and Bessemer platforms in 1995, the first monopod facilities in the UKCS. He now provides guidance to BP's global operations on structural/civil engineering issues and in particular minimum facilities design.

Bob Robinson is a business development manager with Granherne. He holds doctoral degree in offshore wave energy structures. He has been responsible for installation, structural engineering, and field development planning for oil and gas projects over the last 18 years with Halliburton Companies. His work extended into minimum facility cost reduction and the development of the highly successful "Gatherer" design and the patented Sea Access Wellhead (SAW) concepts.