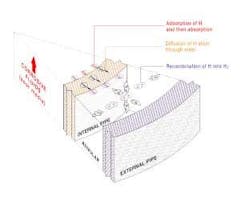

Production from deep offshore oil and gas fields often requires good thermal insulation to limit the risk of hydrate formation or wax deposition. Pipe-in-Pipe structures (PiP) are one of the most effective solutions for obtaining low thermal conductivity values (U-value). Their effectiveness as an insulation system can be impaired, however, by the presence of hydrogen in the annulus.

The goal of the Hypip joint industry project (JIP), launched recently by Institut Français du Pétrole, is to analyze how the fluid composition flowing inside the PiP may damage the thermal insulation through the generation of hydrogen in the annulus, and also to evaluate potential remedies.

Numerous laboratory studies have been devoted to hydrogen charging into steel when exposed to sour media. However, the hydrogen permeation is strongly dependent on the hydrogen charging condition (sour corrosion) and extraction power (respectively low and high for thick and thin steel membranes). For instance, for thin steel membranes (approximately 2 mm), permeation rates as high as several kPa/day have been detected for an annular space arrangement of one inch.

To achieve comprehensive measurements on a 1-cm thick pipe, a full-scale corrosion loop has been built by IFP, dedicated to hydrogen permeation. This loop, operating with sour gas at up to 1 Mpa, allows the hydrogen permeation rate measurements of up to several tenths of kPa/day for a 1-in. annular space arrangement. As the thermal conductivity of hydrogen is five times higher than that of air, the benefit of the vacuum is lost at only 20 kPa, i.e., within a couple of weeks.

The JIP program will also measure hydrogen flux for various pipe thicknesses exposed to aqueous solutions of pH values ranging from 4 to 6.5, containing dissolved gas (CO2 + H2S), with or without corrosion inhibitor. All experiments will be correlated with commercial hydrogen permeation and corrosion probes.

Re-assessing flow assurance

In association with DNV, IFP is also launching a new JIP called Famus (Flow Assurance by Management of Uncertainties and Simulation), which aims to develop models for analyzing flow assurance issues under an economic perspective.

Hydrogen, via a corrosive reaction, may impair the thermal insulation efficiency of Passive PiP systems.

null

The approach developed with DNV will allow the consequences of flow assurance problems to be analyzed, using models representing physical phenomena such as flowing conditions, hydrate plug formation, and wax build-up. All this will be coordinated within the framework of an integrated approach to risk and uncertainty management. The information provided by the model will permit assessment of the necessary balance between Capex, Opex, and Riskex (costs associated to unplanned events) related to losses of production, over a life-cycle perspective.

This JIP is open to operators and contractors interested in flow assurance, with a focus on ultra-deepwater developments and long-range transportation pipelines. Sponsors will benefit from the development of new methods that will provide:

- Life-cycle analysis of flow assurance solutions

- Production system availability/safety evaluation

- Ranking of flow assurance solutions according to risk preferences

- Identification of the main risk drivers in various flow assurance solutions

- An explicit account of the uncertainties in the available infor-mation

- Determination of the critical parameters and critical uncertainties

Such an approach has already been tested on a simplified production system, using prototype software.

For more information on Hypip, contact [email protected], [email protected] or [email protected]. Further information on Famus is available from [email protected] and [email protected].

More flights to remote sites

Air France has launched Dedicate, a new series of scheduled routes and direct flights to some of the more remote oil and gas centers in Asia and West Africa.

Subject to granting of air traffic rights, the company plans to offer twice weekly flights from Paris-Charles de Gaulle airport to Doha, Qatar; Kish Island, Iran; Kuwait; Malabo, Equatorial Guinea; Pointe Noire, Republic of Congo; and Tashkent, Uzbekistan. Atyrau, Kazakhstan, is another planned destination.

All flights will operate using 82-seat Airbus 319-100 ERs, with business and economy seats. Limited traffic on these routes, and airport infrastructure in certain cases, rules out use of wide-body jets. Air France has chartered five aircraft for the Dedicate service, four of which were due to be delivered to the company this month. Since January, it has chartered French airline Aero Services to operate the Malabo and Pointe Noire routes. The new service is also open to the 1,000 member companies of Air France's Petroleum Club.