System compatible with all subsea vendor configurations

Tom Bryce

Enpro Subsea

As fields mature and production rates begin to decline,subsea intervention plays an increasingly important role in maximizing recoverable reserves.

There are almost 6,000 subsea trees installed in shallow, deep, and ultra-deepwaters worldwide, but subsea wells typically produce 10-30% less hydrocarbon than equivalent platform-based wells. The main reason for the difference in performance is the complexity and cost of monitoring, measurement, and intervention on subsea wells. Typically, recovery without regular intervention is only 22% of available reserves, although appropriate intervention could increase that figure to 50%.

The challenge for operators has been to find cost-effective methods that provide the flexibility required to enhance subsea production throughout the life of an asset. Conventional liquid intervention systems involving rig-based intervention, via the tree or a choke-replacement system, are constrained by the wide array of individual manufacturer specifications, varying interfaces, crossed license agreements, increased payloads, flow restrictions, and limited workover access. An intimate knowledge of “as built” and “as installed” engineering is also required for each tree.

Decisions onsubsea production systems are often based on limited information obtained from exploration wells. How production and water injection wells will behave over their lifecycle is, therefore, uncertain. Unlike a topsides well, which can be accessed at any time, a subsea well requires coordination of significant hardware - rig, vessel, equipment and so on - to enable access. Measures such as logging, zonal isolation, and mechanical intervention, which typically require a mobile offshore drilling unit (MODU) or light well intervention (LWI), are often prohibitively expensive.

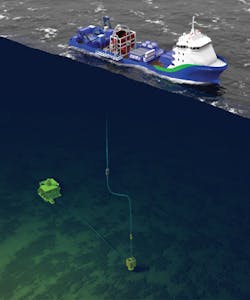

To address these various issues, Enpro Subsea has developed the Enhanced Subsea Sampling & Injection (ESSI) system which can be adapted to any subsea tree or manifold for accessing hydrocarbon flow subsea to facilitate a range of applications including well control, scale squeeze, acid stimulation, fluid sampling and multiphase metering. It provides a universal “open standard” interface that can be deployed at multiple locations, including the jumper hub, pipeline end termination (PLET) or manifold.

The team behind the development was also responsible for theMARS (Multiple Application Reinjection System) which Cameron acquired in 2007.

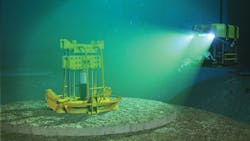

The ESSI flow access hub is a safe access port for well or pipeline operations that can either be retrofitted into existing subsea hardware or seamlessly integrated into a new field development. It is located “off the tree” and comprises key subsea components that can be standardized to enable fasttrack procurement, giving operators the ability to manage production efficiency as required across all phases of the project cycle.

The patented Flow Access Module (FAM) hub can be supplied in a single or dual-port version either with new hardware or permanently retrofitted onto existing infrastructure. It can be located at the PLEM, PLET, or flowline termination, tree or manifold. The modular design, employing standard “off-the-shelf components,” provides a universal subsea interface with an “open standard” design that supports all vendor configuration, manufacturers and regions.

The ESSI fluid intervention system can be configured for single-vessel operations, significantly lowering the economic threshold of deepwater well control, scale squeeze and acid treatments. It can withstand significant loads and gives operators access to a comprehensive range of production enhancement tools. With the FAM hub in place, a range of interchangeable units can be deployed allowing numerous optimization solutions to be enacted individually, concurrently or in combinations from the first day of production onwards. These enable multiple enhanced production solutions such as flow assurance, well control, scale squeeze, acid stimulation, hydrocarbon sampling, multiphase metering or multiphase pumping.

To reduce the risk and costs associated with fluid intervention, the ESSI system bypasses the traditional approach of squeezing wells via a MODU, LWI vessel or multiple vessel solutions using separate intervention and stimulation packages. Instead it combines storage, pumping, delivery and deployment equipment onto a single optimized vessel deck. The ESSI Flow Intervention Services (FIS) are universally applicable and interface to all well access points, such as the tree cap, a MARS-enable choke or ESSI FAM hub.

The ESSI head is a lightweight ROV-installed solution that minimizes deployment loads onto the receiving structure. It provides automated flow control and shut-off which further reduces the complexity and footprint of the deployment system, enabling multi-well campaigns from a single vessel.

Potential FIS operations include:

- Well fluid treatments and sampling

- Well flow rate, water cut, sand production monitoring for well performance and production system integrity

- Well pumping to increase well flow rates and recoverable reserves

- Well solids removal/treatment

- Well kill and control

- Production flowline integrity, providing flow access and flowline de-sanding and de-wax treatments.

The system has further variants that allow operators with gravity-based structures to fulfil commissioning obligations in compliance with OSPAR convention guidelines. The ESSI decom systems uses a patented anchor hub that locks onto the cell top of gravity-based structures, enabling drilling, sampling and pumping operations via a safe and secure connection.

ESSI systems are being manufactured for programs in the Gulf of Mexico, West Africa, and the North Sea. This month, a US operator will take delivery of ESSI Flow Access Modules (FAM) and intervention hubs in the GoM. The dual-bore FAM hubs will enable multiple applications, including:

- Managing production by allowing retrievable flowline instrumentation such as multiphase metering, water cut metering and acoustic sand detection

- Mitigating hydrate remediation risk through retrievable chemical injection (methanol)

- Maximizing production through reservoir stimulation (squeezing).

Additionally, ESSI FAM intervention hubs are under construction for production optimization at facilities offshore West Africa.

Since October 2015, an ESSI decom system has been used in the North Sea to remove trapped fluid from a concrete gravity-based structure during decommissioning.