A new dual gradient drilling technique was featured at the Gulf Coast Section SPE General Meeting. Successfully tested in the US Gulf of Mexico, the Norwegian North Sea and offshore Cuba, the technique holds promise for future development of areas characterized as having severe drilling challenges.

One such well, offshore Cuba, had a highly permeable carbonate section that created extreme lost circulation issues, defying all prior attempts to penetrate it to test promising strata lying below it. The operator reported both good news and bad news. The good news was that it was able to successfully penetrate the previously undrillable lost circulation zone using the new technique. The bad news was that the targeted reservoir was dry. Nevertheless, valuable learnings were derived from the event which have been implemented and tested on a subsequent well in Norway's Troll field.

A bit of history

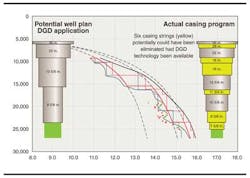

Two techniques are under study to successfully and safely drill those sections with tight drilling margins. The first, lately implemented by Chevron, follows the lead demonstrated by Diamond Offshore's semisubmersibleOcean New Era in conjunction with the DeepStar consortium. In 2001, the Ocean New Era drilled a test well using the seabed mud lift (SML) concept, which essentially placed a mud pump on the seabed to lift mud returns to surface in a dedicated conduit instead of conveying them in the riser-drill pipe annulus. The principle is simple. Imagine that the hydrostatic pressure of thousands of feet of heavy drilling fluid in the riser is removed—as if the rig were sitting on dry land. Since many shallow beds just beneath the mudline cannot withstand the hydrostatic pressure of a long column of heavy drilling fluid, the technique immediately enables safe drilling of those shallow unconsolidated sediments. It also reduces the need for multiple protection casings or liners, each one reducing the borehole diameter. The effect of multiple strings could be when finally the target formation is reached, the casing would be too small to accommodate the completion hardware.

DeepStar proved the concept. Static bottomhole pressure and equivalent circulating density could be controlled to maintain a safe drilling margin without exposing unconsolidated sediments to fracture pressures or risking influx of formation fluids.

Chevron has equipped one of its contracted drillships, thePacific Santa Ana, to enable it to perform dual gradient drilling using the SML technique.

A different approach

Believing that a technique that eliminates the SML module would be more flexible and more easily adapted to any rig design, Transocean developed the continuous annular pressure management technique. With no subsea modules involved, all equipment can be continuously monitored and maintained. Basically, on the rig, the mud returns are separated in a centrifuge to segregate the weighting material, effectively diluting the mud. The heavy mud is returned to the suction pit where it can be circulated down to the drill bit. The light component is pumped down to the mudline, where it re-enters the riser and blends with the returning mud from the bit, thus reducing hydrostatic pressure at the seabed. The effect is not as great as that produced by the SML technique, but it is sufficient to permit safe drilling of tight drilling margins. Transocean maintains that its system can be deployed faster to any of the drilling rigs in its fleet. All rig equipment is modularized and can be installed and activated quickly using rig equipment and personnel.

A new approach

Under the sponsorship of Statoil, a new technique for managed pressure drilling has been introduced. Called EC-Drill, it promises to allow the quick, safe drilling of tight margins. The system can apply (or withdraw) hundreds of psi of mud pressure in a few minutes allowing equivalent circulating density (ECD) to be almost instantly controlled while drilling, or during connections and subsequently, when the rig pumps are re-engaged. At the heart of the new system is a subsea pump module connected to the riser on a special riser joint several hundred feet below the sea surface. Three disc pumps in series pull drilling fluid returns from a port in the riser and route them to the surface in a mud return line using an unused slot in the riser system. The rig pumps operate as usual, supplying weighted drilling fluid to the bit. The ECD, however, is controlled by adjusting the level of drilling fluid in the riser using the disc pumps. Very precise sensors provide pressure data at the EC-Drill riser joint. They have the capability of instantly detecting, and quantifying an influx (kick) or a loss (formation breakdown). This gives the operators almost immediate response capability to mitigate ECD fluctuation. The mud level in the riser annulus moves up and down like the fluid in a manometer maintaining the desired bottomhole pressure. How deep the EC-Drill riser is deployed determines the pressure range under the system's control. Recent experience using a special riser deployed at about 1,000 ft (304.8 m) below the surface gave roughly a 700 psi (48.3 bar) range.

An operations module in the driller's cabin provides easy-to-read and interpret graphical readouts and the most critical data are remote to the driller's console. The downhole pumps, valves, and sensors are fed by an umbilical cable deployed from the surface. A 1.35 MW power supply with variable speed drive powers the downhole system. Safety is assured; if any of the EC-Drill system components fail, the rig pumps can take over and the principle mud pressure barrier maintained. Drilling can continue normally using the rig's circulation system.

To date, four wells have been drilled using the EC-Drill system and two more are under way. The technique has been vetted and approved by Norway's North Sea regulatory authorities and has received DNV certification.