Hurricane lessons bring new rules, floating system designs

Gene Kliewer, Technology Editor

Offshore development designs and design criteria are moving targets marked by regular innovation and change.

Innovation can take the shape of a vessel design, and change can result from weather extremes.

Both of these are at play in the Gulf of Mexico today, and they are changing the way projects are approached by everyone from the operators and classification societies to the API and Minerals Management Service (MMS).

Traditional design criteria took a hit, along with 300 production platforms, 32 deepwater production installations, and 30 mobile offshore drilling units (MODUs), when hurricanes Katrina and Rita blew away the benchmark metocean averages on which designs had been based.

One obvious result is that the GoM now has been divided into four areas ranked by the frequency and severity of the storms through each area. Each zone was given new metocean criteria that must be accommodated. The most severe storms have historically traversed the central region, which spans from about New Orleans, Louisiana, on the west to the Florida panhandle on the east. There now are new height-above-wave criteria for platforms and new interim mooring standards for deepwater GoM operations, and more changes are coming.

MODU designs are responding to both the increasing operating depths being explored in the GoM and to the new metocean data being applied to such vessels by regulation. These changes are coming from a joint industry study by the MMS, US Coast Guard, and operator representatives. For this year, there are interim API guidelines in the form of API RP-95F. It includes items about site and well-specific data, design criteria for the mooring, indicative GOM hurricane extreme metocean conditions, mooring analysis, site-specific risk assessment and mitigation, mooring hardware issues such as anchor system and mooring system upgrade, and mooring operation issues such as deployment, hurricane preparedness, and inspection. These guides apply only to MODUs. Other revised guidelines on such things as production operations remain to come.

New rules coming

More new rules are expected to be released in the next month or two regarding all floating offshore installations. Those new rules will be influenced by the common ships rules recently agreed upon by the International Association of Classification Societies. The IACS members addressed differences among themselves to improve commonality.

“There is a constant review that is done to our rules to make sure they are applicable, that we are always updating our rules to reflect the most accurate methodology of empirical work, and that we are reflecting the true experience profile in our rules,” says Rod King, global FOI business manager for Lloyd’s Register North America Inc.

“We as an industry are having to be highly innovative in our concepts and our methodologies in getting facilities on location,” King adds. This creates its own set of challenges.

One challenge is new designs that no longer fit into a single category of vessel. Operators and vessel designers are combining ideas from existing spars, TLPs, and semisubmersibles into new configurations. The growing list of examples includes deep-draft semis, multi-column floaters, the MinDOC3, and others. The trend has moved into FPSOs, too, where Petrobras has two new design concepts that are not ship-shaped.

“Hybrids are making changes in our approach to rule-making,” says Joe Rousseau, manager, Offshore Engineering, ABS Americas Division. “How the structure behaves will determine the rules to be applied” rather than the shape or application. “Also, questions about how the motion affects components on the topsides will factor in. There might be operational restrictions which would be put in place by operators to lessen the loads during hurricane season, such as reducing deck load.”

Risk-based approach

In the broad sense, designs are being reviewed using a risk-based approach rather than the traditional prescriptive regulations. Rousseau cited the FPSO at Agbami, Nigeria, as an example of an instance where the topsides were given a risk-based review.

“Risk-based has its own challenges,” Rousseau says. “You have to put in place the risk evaluation criteria at a very early stage in such projects so that all parties have a clear understanding of the scope of the verification required.”

Other examples of offshore facilities that do not fit into existing categories well are single-point mooring and floating LNG facilities.

“When you start moving in to new areas like floating methanol or LNG facilities, there are areas that are unique to those facilities,” says King. In those circumstances, he says, it behooves the operator and contractors to call in the classification society early on, even as early as the FEED work. Lloyd’s Register, ABS, and others have consulting branches to work in these areas. The class society can help identify where additional studies or engineering are needed in order to anticipate the actual detailed engineering classification review later in the process.

One thing the certification authorities have done to shorten the entire review cycle is to issue type-approval certificates for some of the equipment and components that go into the finished project. Examples of this are unbonded pipe and valves.

“We would review the design premise, the design methodologies, the manufacturing processes, materials selection, quality control, and, if all that passes muster, we would issue a type approval certificate which says that as long as the manufacturer stays within these boundaries the item is certified,” says King.

To maintain the level of performance, Lloyd’s would do periodic random checks to ensure the manufacturer is maintaining the level of performance that received the certificate in the first place.

New designs

ABS says it is seeing designs that combine ideas from spars, TLPs, and semisubmersibles and arrange them in novel configurations. “We see a crossbreeding between traditional floating production installations resulting in entirely new designs,” says Kenneth Richardson, ABS VP of Energy Development. “These hybrids are unlike anything we have ever seen. From a class society perspective, the issue is which of our existing rules or risk methodologies should be applied so review of these new structures can move forward offering the same safety equivalencies to more traditional designs.”

One example is a cross between a semisubmersible and a truss spar called the MinDOC3 by a joint venture of Keppel FELS and TexBASS. It is intended for the Mirage field in GoM Mississippi Canyon 941 for ATP. It has three vertical columns arranged in a triangle and connected to pontoons. It resembles a semisubmersible, but behaves like a spar. The risers would be tensioned by a hydraulic system rather than the buoyancy cans used on a spar. The topsides are untraditional, too. There is a “T” shaped arrangement.

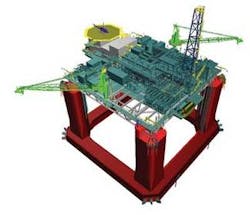

Another cross between a spar and a semi is the multi-column floater under development by AGR Deepwater Development Systems. It is aimed at drilling and production of high-pressure/high-temperature fields in deepwater. The hull is a deep-draft semi with longer columns than conventional semis. Each column consists of four smaller, closely spaced tubes, as in a cell spar. AGR says the columns are affixed to a base pontoon that is flooded during operations. The drilling and production riser support is different, also. The well deck is on a buoyancy module that is vertically restrained by risers fixed to the seabed. This allows the hull to move without imparting as much stress onto the risers.

“Deep draft is a relative term,” says Exmar Offshore Co.’s Jay Cotaya. “It normally implies that the draft of the vessel is deeper than the industry has become accustomed. In this context, it means sufficient draft to greatly reduce the motions of the vessel, in particular heave.” As an example, Cotaya cited Exmar’s E-II drilling semi with an operating draft of 18 to 21 m (59 to 69 ft) while its deep-draft OPTI-EX production semi design has an operating draft of 26 to 30 m (85 to 98 ft). It features Exmar’s “dog-bone” lip on the edges of the pontoons, which are designed to reduce motion. The columns can be as tall as necessary to achieve the motion characteristics required, says Cotaya.

Exmar is building a speculative vessel using the OPTI-EX design. The hull is under construction at Samsung in Korea while the truss deck and topsides are scheduled for Kiewit Offshore Services in Ingleside, Texas. The hull is to be mated with the deck and topsides at Kiewit, also. Delivery of the commissioned vessel is scheduled for 1Q 2009.

“Deep draft semis can be used virtually anywhere in the world,” says Cotaya, “but our first target market is the Gulf of Mexico. It can be used in West Africa, Brazil, Southeast Asia, and areas of the North Sea if equipped properly.”

The purpose of the OPTI-EX design is to give an effective development vessel for marginal fields and to serve as an early-to-market production facility. It also can be used as a redeployable satellite to a hub production facility, the company says. It integrates the hull and topsides, gives a good payload to hull weight ratio, and has attachment areas for multiple risers including SCRs.

The DeepStar project also is working on a deep-draft semi design for HP/HT application in that the riser system will have a high integrity pressure protection system. The deep-draft design aims to keep the pontoons below the wave loading zone to suppress motion. Again, the vessel motion affects the riser system feasibility. The natural periods of the deep-draft semi are above those of the wave.

The deep-draft semi destined for Chevron’s Blind Faith field in Mississippi Canyon 695 and 696 is a hybrid because of its hull and ballast system. It looks like a semi, but ballasts like a spar.

The first deep-draft semi resulted from a collaboration of Atlantia Offshore Ltd. and its sister company GustoMSC. The main design criterion was SCR behavior in ultra deepwater, particularly the cyclical loading caused by vessel heave and pitch. By increasing the vessel draft to 105 ft (32 m), the ring pontoon could be moved below the wave zone to reduce wave motion and to give more water ballast capacity. The Independence Hub was Atlantia’s first deep draft semi. It has a second under way for Thunder Hawk field in GoM Mississippi Canyon 736.

“There are two major reasons for selecting a deep draft semi,” says Lars Felix of GVA Consultants, a KBR subsidiary. “The upper end of the SCR must withstand extreme forces, while the end at the touchdown area must withstand fatigue. And, the deep draft semi is ideal when dry trees are preferred.”

In the GVA design, the pontoons are not as wide as in a traditional semi, and this enables better vertical motion behavior in particular. Felix says the conceptual studies indicate that the displacement and payload of its deep-draft semi design are comparable to existing designs, with displacement ranging from 40,000 to 130,000 metric tons (44,092 to 143,300 tons).

Technip has a design for a deep-draft semisubmersible platform. It has a barge-type deck holding the topside facilities which can be mated to the structure at a yard in minimal water. The legs are pulled up through the deck for delivery to the offshore site, then the deck is raised/base is lowered for mooring on location. According to Technip, the platform is self-installing, requiring no heavy-lift vessel.

FloaTEC is developing structures designed to work well with dry trees to facilitate well intervention without having to contract a MODU. Its ring spar configuration retains the motion characteristics of a truss spar because the exterior shape is the same. The hull has an integrated framing system. The primary girder stiffening of the outer shell, centerwell, and horizontal bulkheads (flats) is a rigid-frame system. These rigid frames are arranged in a radial shape so there are no ovaling or complex girder buckling issues as the girders span longitudinally from flat to flat.

Another design under way at FloaTEC is the DryCenterwell Spar. In this design, the centerwell is closed for added buoyancy. Studies indicate there may be some other advantages such as the ability to carry asymmetrical bay layouts and a smaller diameter per payload.

A Society of Petroleum Engineers study group is investigating a central pontoon semi as a production facility for deep and ultra deepwater. This design has an eight-sided continuous central pontoon with four radially oriented columns outboard of the pontoons. This configuration is thought to improve the stability of the vessel during topsides integration dockside. It also would use less hull steel because it would not need as much compartmentalization of the pontoon.

Modec is developing a Self Stable Integrated Platform in a TLP configuration. The base and tendon support structures are set at a deep draft, and the tendons are connected to the sea bottom. Modec says the design can support drilling or workover rigs and a large number of top tension risers and flowline risers. It is wet- or dry-tree compatible. The configuration also can work in waters deeper than traditional TLPs, Modec says.

Petrobras is working on a new hull production unit concept called MonoBR. The MonoBR is an FPSO that is not ship shaped. Rather, it is a short, cylindrical mono-column floater. It has spar characteristics, but the draft is much shallower. Petrobras says the design reduces heave and pitch, which benefits steel catenary riser fatigue life.

IACS members

- ABS

- Bureau Veritas

- China Classification Society

- DNV

- Germanischen Lloyd

- Korean Register of Shipping

- Lloyd’s Register

- ClassNK (Nippon Kaiji Kyokai)

- RINA (Italy)

- Russian Maritime Register of Shipping.