Designed buckling for HP/HT pipelines

Nils Øvsthus Kristiansen

Sarawak Shell Berhad

Ralf Peek

Shell Int E&P BV

Knut Tørnes

IKM Ocean Design

Malcom Carr

Boreas Consultants Ltd

The industry’s traditional method of controlling thermal buckling is to trench and bury the line, effectively fixing the pipeline configuration. However, as pipelines are operating under increasingly higher temperatures and pressures, the amount of overburden load becomes uneconomical. According to Sarawak Shell, a more cost-effective design strategy has been adopted consisting of installing the pipeline on the seabed and allowing the pipe to buckle laterally during operation. Shell adopted the innovative design approach by controlling the lateral buckling behavior using a pre-installed vertical trigger and pipeline anchor structures on the seabed.

Sarawak Shell Berhad has added several inter-field pipelines to the existing network off the coast of Borneo over the last few years and more green fields are being developed. These new inter-field pipelines are operated at high pressure and high temperature (HP/HT), and are installed on an even seabed within a relatively short distance, giving them the potential for lateral buckling and axial walking.

The Sarawak Shell inter-field pipelines are located in the Central Luconia field off the west cost of Borneo. Four HP/HT lines are in operation, and three are under development. All are corrosion resistance alloy (CRA) pipelines ranging from 10 to 21-in. in diameter. The shut-in pressure for the pipelines is as high as 310 bar and design temperature up to 140° C. The seabed on the Central Luconia field is relatively flat and of soft clay.

Lateral buckling and walking

A hot pipeline that is laid on the seabed will tend to expand. If this thermal expansion is restrained in some way, for example by the friction of the seabed, then an axial compressive force will develop in the pipeline. If this force is large enough, the pipeline may undergo column buckling. The buckles will occur at locations with critical combinations of driving force, imperfections from an idealized straight pipeline route and lateral restraint. Imperfections can result from an uneven seabed, the laying process, or wave and current action.

For an exposed pipeline, thermal feed-in from several kilometers of pipeline may feed into a single buckle site. In this case, the stresses and strains in the lateral buckle may become excessive and need to be addressed in the design. An added challenge when dealing with HP/HT pipelines is that very large end expansions may result that can be very difficult to accommodate by traditional tie-in spools.

Another phenomenon that needs to be addressed for HP/HT pipelines is walking. This may cause an entire pipeline to walk from the hot inlet end toward the colder outlet end. The process is driven by temperature gradients along the length of the line. Such a gradient causes the same displacements as a distributed axial load applied to the pipeline with the axial force per unit length that is proportional to the temperature gradient.

The highest gradients occur under transient conditions, when hot production starts flowing into a cooled line. This is the most critical condition for driving pipeline walking. Short pipelines subjected to repeated heat-up and cool-down cycles are particularly prone to walk.

To date, most seabed inter-field pipelines have been trenched and backfilled. In these cases, the pipeline is restrained from horizontal or vertical movement. A more cost effective approach is to allow the pipe to buckle on the seabed in a controlled fashion to accommodate thermal expansion. This approach relies on adopting limit state design codes, the application of state-of-the-art numerical simulation techniques, providing detailed information of all key design parameters, and monitoring of the pipeline behavior after start-up.

Design approach

Traditionally, design codes have been based on simple stress-based criteria limiting the stress to the elastic range. However, these criteria are not suitable for demonstrating pipeline integrity of HP/HT pipelines. The simple stress-based design codes are too conservative.

As an alternative, the project has adopted a limit state and partial safety factor approach. This has involved identifying the main failure modes and assessing them separately. For lateral pipeline buckles the most relevant failure modes are local buckling, fatigue due to cyclic loads resulting from repeated heat-up and cool down cycles, and fracture at the girth welds.

The formation of the buckle is the key uncertainty in any lateral bucking design. The project has developed detailed numerical finite element (FE) models for simulating the in-place behavior of the pipe. The 3D FE model is able to model the full load history including installation and start-up/shut-down cycles, and account for material and pipe/soil break-out effects.

To accurately model the structural response of the pipeline system it was necessary to provide accurate information on the mechanical properties of the pipeline material and welds, pipe/soil interaction, and as-layed out-of-straightness data. Project specific testing programs were undertaken to make material data available relevant to the CRA pipelines. Soil sampling and testing was conducted to provide accurate pipe/clay resistance curves. Furthermore, imperfections along the pipeline route are assessed based on as-layed survey data to confirm imperfections assumed in design.

Structural reliability methods were adapted to rationally treat the various sources of uncertainty involved in the buckling analysis.

Pipe-seabed interaction

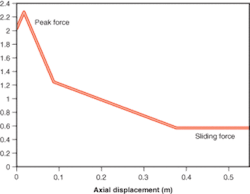

Both buckling initiation and post-bucking response is extremely sensitive to pipe-soil interaction. Pipe-soil interaction is traditionally defined assuming a bi-linear Coulomb friction model. This model assumes a gradual build-up in resistive force until a maximum value is reached, and beyond this point the pipe slides with constant friction restraint.

For pipelines installed on a soft clay seabed, there is an added complication. It involves the force-displacement relation describing the soil resistance to axial movements of the pipeline. Instead of the typical bilinear relation for frictional resistance, the resistance first rises to a high value, called the break-out resistance, before reducing to a much lower residual value at large axial displacements.

A similar shape of the force-displacement relation also applies for the lateral direction: for the pipe to buckle laterally it needs to break out from the embedment. The break-out resistance can affect the length of the buckle, and in turn result in higher strains in the buckle. What has not previously been known is the effect the high axial break-out resistance has on the effective compression force distribution and subsequent buckling behavior.

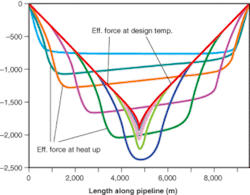

The effective compression in the line is caused by pipe-seabed friction restraining the line from expanding freely. The force is zero at the pipe ends (assuming the pipe is free to expand) and increases up the virtual anchor point where expansion force equals the friction restraining force. Beyond this point, further expansion movement is prevented and the effective force remains constant.

Detailed numerical modeling has been performed to study the effect of the break-out soil resistance. Interestingly, the break-out resistance has a dramatic effect on the effective force distribution during initial heat up to operating condition. The maximum effective force may temporarily be significantly higher than the peak force compared to the effective force corresponding to uniform sliding friction. This affects the length of the pipeline route susceptible to lateral buckling, and the interaction between buckles.

Buckling initiation strategy

When allowing the pipe to buckle laterally, a key requirement is to ensure that several buckles will form so that the available thermal expansion will be shared by several buckles rather than localized in a single buckle. This will reduce the stress level at individual buckle locations. A further requirement is to reduce the risk of interaction between individual buckles.

A number of recent industry projects have adopted techniques that increase the robustness for thermal buckling to occur at preferred locations. The common denominator for these techniques is to reduce the critical buckling force at the selected buckle locations. By doing this the probability for buckling at these locations increases, and hence, reduces the probability for buckling at adjacent sections.

For the Sarawak Shell inter-field pipelines in operation, man-made vertical imperfections were installed along the pipeline route to promote frequent buckling. The imperfections are introduced by pre-installing trigger structures on the seabed. In cases where the free-span created by the trigger is found to be a design issue, the pipe has been designed to fall off the trigger as it heats up. Pipeline anchors have also been installed to limit the pipeline end expansion.

There are inherent uncertainties in the bucking and walking response of the system. Hence, operational monitoring is performed to ensure long-term integrity of the pipeline systems. Monitoring will be conducted throughout the service life of the pipelines to verify the locations and amplitude of the lateral buckles, pipeline end movements, as well the related load history, defined by the pipeline pressure and temperature during operation.

Surveys after start-up of the lines have in general shown good agreement between predicted and actual buckling formation. Areas that are in the process of being further developed include reducing uncertainty in the clay/pipe interaction and increasing the understanding of the relevant failure modes, including low-cycle fatigue properties, for the CRA line pipe.•