SUBSEA/SURFACE SYSTEMS

Record-breaking contract

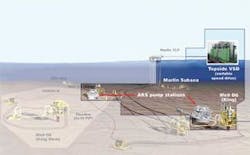

Aker Kvaerner Subsea has been awarded a contract for delivery of two subsea pump stations worth $33.7 million. This deal sets a new world record by applying the technology in the deep waters of the GoM, more than 18 mi from the host platform.

The contract calls for delivery of two subsea, twin-screw pump stations, as well as one spare pump to be installed on BP’s King field in 2007. The King field complex will tieback to the Marlin TLP, located 18 mi away. The field’s water depth ranges from 5,000-6,000 ft.

The contract also calls for delivery of modules with manifolds, variable speed drives, topside and subsea control systems, topside lube oil hydraulic power units, and high-voltage connectors and jumpers.

“This technology has enormous potential for the GoM and West Africa,” says Raymond Carlsen, Aker Kvaerner Subsea’s executive VP. “The installation of these pumps will extend the production lifetime of the field and increase the ultimate oil recovery for the operator.”

Kvaener has been developing the technology with the funding of the Norwegian government and major oil companies, and it can enhance production in both shallow and deepwater applications, Carlsen says.

The pump station systems will be manufactured at Aker Kvaerner Subsea’s facility in Tranby, Norway.

ROV completes Casino program

Fugro Survey Pty Ltd.’sSealion ROV has finished wellhead completions work on the Casino field, offshore Victoria, Australia. The ROV was implemented by Australian E&P company Santos onboard Diamond Offshore’s mobile offshore drilling unit Ocean Patriot.

TheSealion ROV performed tree installations, inspection, hot stabs, various torque tool interface operations, and debris clearance surveys, as well as normal drill support duties. The vehicle has been employed onboard the rig for the last four years, and in that time has become an integral part of the Ocean Patriot’s operations.

Peter Dodd, completions team leader for Santos, says, “The ROV performed all operations unobtrusively, efficiently, with a minimum of fuss and was ready to go when called upon.”’

The project involved the installation of subsea trees on two wells (Casino 4 and Casino 5), which will produce through 38 km of 12-in pipeline to the existing onshore Iona gas facility. First gas production is expected in early 2006. The Casino gas field is located 30 km offshore Port Campbell on Victoria’s southwest coast.

Fugro facilitates early production from Sapphire

Fugro Survey Ltd.’s construction support vesselSkandi Carla facilitated early production from Egypt’s Sapphire gas field. The vessel’s two Triton XL work class ROVs were used to turn the subsea valves enabling Egyptian LNG Train 2 gas production to flow from the field in early September.

Sapphire’s commissioning operations were carried out in over 300 m of water depth and involved ROV hot stabs and the application of torque tool equipment. Throughout the year-long campaign on the Simian and Sapphire fields,Skandi Carla’s two Triton XL ROVs performed over 1,100 project ROV dives in water depths ranging from 20 m to 1,000 m.

Many of the subsea intervention tasks required simultaneous ROV operations. The moonpool-deployed ROVTXL27 and the over-the-side deployed ROV TXL27 successfully completed over 730 and 450 dives, respectively.

Fugro Survey Ltd. worked closely with Technip, onboardSkandi Carla, to perform the deepwater flooding, pigging and hydrotesting operations. These operations included Remote Flooding Module (RFM) tasks that formed part of the overall subsea commissioning program.

Survey works carried out from the ROV involved more than 40 acoustic metrology tasks, several hundred kilometers of ROV multibeam pre- and post-lay surveys, and numerous engineering driven specific measurement tasks.

High-level overviews and close detail survey scopes were combined to give the necessary information in a timely and appropriate manner, depending on the client requirements.

In addition to the ROV intervention tasks undertaken, theSkandi Carla’s heave compensated crane was used to deploy the pig launcher and receiver heads in over 1,000 m water depth. These lifts weighed over 35 tons each.

Additional tasks included concrete mattress deployment and associated pre- and post-installation survey operations.

Mechanical handling contract

Patriot Mechanical Handling will supply a new Subsea Handling System to Pride International for application in both the US and Brazil.

Patriot also won a smaller order from Petrobras for the refurbishment of pipe-handling equipment. The value of the orders is in excess of $1 million. Patriot CEO Paul Findlay says of the news, “Patriot’s success in winning new orders and new clients is testament to the quality and range of the company’s products, and to the hard work of the team based in Houston, Texas.”

“All subsidiaries are performing well and are expected to meet their budget forecasts,” he adds. “Under the new operating structure we have seen a further improvement in marketing activity and, most importantly, in delivery and service levels. We remain confident regarding the outlook for the company.”

Collaboration on well abandonment

WellCut Decommissioning Services and TSMarine (Contracting) Ltd. have signed a master service agreement (MSA) that will guarantee WellCut support for its subsea suspended well abandonment activities over the next three years.

TSMarine will provide WellCut with dynamic positioning (DP) vessels and associated ROV, positioning, engineering and project management services. In 2006 alone, this is expected to result in over 100 days of vessel utilization.

TSMarine and WellCut will also cooperate on the development of a well abandonment support package (WASP). The WASP system will enable access to a larger number of subsea wells from a DP vessel for suspension and decommissioning operations than is currently possible.

TSMarine Managing Director, Alasdair Cowie comments, “The MSA and WellCut’s involvement...demonstrate significant confidence from our two companies in a joint assault on the subsea decommissioning market.”

Tom Leeson, WellCut’s business development manager, says, “These agreements demonstrate our long-term commitment to the decommissioning market, both in the UK and abroad.”•