Cost-effective removal of subsea exploration wellheads

Eric A. Senior - Global Industries Ltd.

Svein H. Sølversen - Norse Cutting & Abandonment Inc.

One alternative to exploration wellhead recovery operations normally carried out by a drill rig is Norse Cutting & Abandonment’s Subsea Wellhead Picker. Global Industries’ newly deliveredOlympic Challenger DP MSV, and NCA’s rigless subsea wellhead recovery tool recently were applied in the North Sea.

Rig Chase method

The conventional method to abandon exploration wells uses the drilling rig to plug the well, cut the wellhead (using either explosives or mechanical blades), and then recover the wellhead. The Rig Chase method lets the drilling rig move to a new location to drill while a DP MSV conducts the wellhead removal campaign, thus the term “chasing” the rig.

This approach can save up to 60% in abandonment costs and three to six days of rig spread time.

Dimensions: 2,208 x 1,390 x 1,390 mm

Weight in air: 3,500 kg (including landing frame)

Net weight: 2,915 kg (without landing frame)

The Subsea Wellhead Picker (WHP) combines a connector that latches onto the wellhead and the Internal Multi-string Cutting Tool (IMCT). The IMCT uses abrasive water jet cutting to sever all the layers of casing in one attempt.

The WHP can run from a DP MSV deployed from either a heave-compensated crane over the side of the vessel or a module-handling tower over the moonpool. At the seabed, the IMCT is stabbed into the inner casing and lowered to cutting depth, typically 15 ft (5 m) below the mudline, where it performs the multi-string cut. Once the cut is completed, the wellhead can be lifted to the surface with the connector.

The system has been field proven for cutting from 7 in. to 36 in. (17 ¾ cm to 91 ½ cm) at water depths to 1,000 ft (305 m). The WHP can remove redundant subsea wellheads, individual wellheads, or wellheads installed in templates.

Features

Features of the WHP include the following:

- Operates from a DP MSV

- Does not require drill pipe or work string

- Cuts and recovers wellhead in one deployment

- No need to reposition vessel during the operation

- The IMCT produces a clean and even cut for easier and safer recovery and handling of the wellhead

- Eliminates hazardous handling of drill pipe or explosive charges

- Cutting is not sensitive to compression in casing and works on centric or eccentric casing, with or without cement in annuli

- Superior cutting speed – typically 1-2 hours cutting time or 6-10 hours roundtrip deck-to-deck

- Stand-alone, rigless surface package

- Computer-based control and monitoring.

DP MSV operation

To prepare, the IMCT is connected to the WHP and pre-deployment tests must be performed. Concurrently, the well is drifted with a special drifting/cleaning tool from NCA and deployed with both the crane and assistance from the ROV. Access to the well at the required depth is verified, then the WHP is deployed using the heave-compensated crane and the IMCT is stabbed into the well with ROV assistance and lowered to the required cutting depth of 15 ft below the mudline. The WHP connector then is lowered onto the wellhead with ROV assistance and activated. A pull test verifies connection integrity.

The IMCT is configured with packers, air, and return lines. Once set, the packers are engaged and the water displaced below the cut line using air pressure. This atmosphere coupled with NCA’s patented abrasive slurry system contributes to each multi-string cutting attempt.

After the cut, the crane is used to break the suction and to verify the wellhead and conductor string are severed. The WHP, wellhead, and conductor stub are recovered to the deck of the MSV, laid out for disconnection, and made ready for deployment to the next well.

With the heave compensation of theOlympic Challenger, for example, operations can be carried out with Hs ≤ 3 m. A typical round trip for WHP is 8-12 hours deck-to-deck.

The wellhead connector (WHC) is part of the WHP and is designed for vessel-assisted subsea wellhead removals. The WHC grips and holds a standard H4 connector to pull the wellhead from the seabed once the conductor has been cut.

WHC specifics:

- Hydraulically activated/deactivated, supplied from topside via an umbilical

- Integrated lifting spread designed for a 200-metric ton pull.

- Tool functions:

- Interfaces with a standard H4 male connector

- Hydraulic set and release

- Bulkhead and interface for easy IMCT interface

- Dogs may be redesigned to fit non-standard H4 profiles.

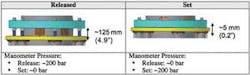

Setting, unsetting

There are two visual indications for determining whether the tool is set (activated) or not:

- Position of activation ring fully set

- Position of activation ring fully released.

A two-position slide valve is installed to flip between Remote (Topside) and ROV hydraulic feed. In case of a contingency, the default position of the valve is in Topside mode. The valve must be flipped to ROV mode prior to ROV operation.

The ROV hot stab is a contingency only. In case of hydraulic supply failure from Topside, an ROV can connect to the WHP/ WHC and use its internal HPU for setting/unsetting.

Case history

Project information:

- Wells: five multi-strings (10 ¾” - 13 3/8” -20” -30”)

- Location: Central North Sea

- Water depth: approximately 140 m (460 ft)

Equipment:

- DP MSV with 150-metric ton active heave compensated crane

- NCA Subsea Wellhead Picker

- NCA Internal Multistring Cutting Tool

- NCA Abrasive Waterjet Cutting

Results:

- No incidents or accidents

- Five successful cuts

- Best roundtrip time deck-to-deck: eight hours

- The world’s first combined P&A and subsea wellhead removal campaign without explosives or mechanical cutters on drill pipe

Further to the case study, using Global’s MSVOlympic Challenger and NCA’s Wellhead Picker showed five specific advantages:

- Cost Savings – The day rate of a Global MSV is approximately 25% of a typical drilling rig spread

- Frees up drilling rig to drill more wells (3-6 days per well). For a 20-well drilling program, for example, 60 to 120 extra drilling days can be made available

- Abrasive cutting method is environmentally friendly

- Abrasive cutting does not impose shock loads to the well as opposed to explosives which can compromise the integrity of the cement plugs

- Wellheads cut with abrasive technology can be refurbished and re-used.