Subsea imaging technology created to help with inspection challenges

Editor's note: This Subsea Systems column first appeared in the January-February 2024 issue of Offshore magazine. Click here to view the full issue.

By Ariana Hurtado, Editor and Director of Special Reports

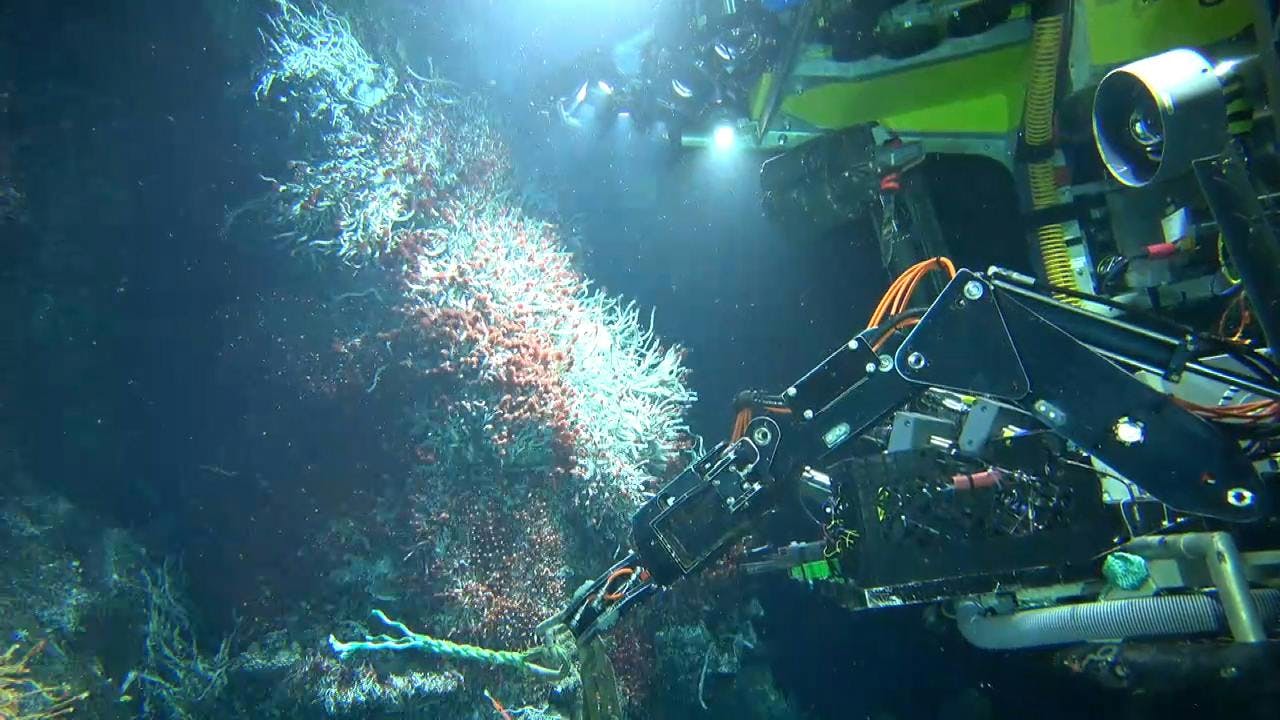

Offshore oil and gas projects routinely call for inspection and survey needs. To help with this, everything from cameras, LEDs and lasers to ROVs and AUVs are utilized, and cloud-based software and comprehensive hardware technologies provide remote operation capabilities.

SubC Imaging, a company that offers remote operations technologies for offshore energy industries, aims to solve remote challenges such as real-time low latency video; securing shared viewing and presentations; redundancy and back-ups; communications between teams and locations; remote piloting and vehicle control; and data capture, recording, logging and eventing.

Adam Rowe, vice president of software with SubC, recently shared with Offshore an exclusive sneak peek of the company's new Rayfin Single-Channel Inspection System (SCI). Available later this spring, this live inspection system combines software and hardware for efficient and organized inspections and surveys. The system combines camera, LED, laser and DVR software technology into one complete tool. It also integrates real-time topside media and data transfer. Unlike traditional systems, Rayfin SCI eliminates the need for downloads, allowing immediate access to crucial data. Looking ahead, a multi-channel version of this Rayfin SCI system is on the company's development roadmap.

"Rayfin SCI addresses key pain points and challenges the oil and gas industry has when it comes to underwater inspections," Rowe said. "These include the need to streamline workflows by eliminating the use of separate software applications, reduce redundancy, enhance user-friendliness, and have better visibility and images."

The technology was designed to provide real-time data transfer, automated organization, and improved live image enhancement and visibility capabilities in challenging underwater conditions. Rowe said these features, paired with Rayfin Rapid Digital Imaging (RDI), can optimize the growing trend of rapid stills inspections within the offshore energy sector.

According to SubC, this is the first technology that offers a complete package for subsea imaging. "The oil and gas sector is looking for complete solutions," Rowe continued. "You don’t need to cobble together piecemeal parts that are hard to integrate with your ROVs. From the camera, lights, lasers and software, Rayfin SCI delivers a system with everything you need for efficient inspections with the highest quality data."

The imaging power of the Rayfin camera is designed to capture the sharpest images, with a scratch-resistant sapphire lens paired with water-corrected LiquidOptics. In addition, the company's RDI technology comes standard with any system. "Instead of video frame grabs, fast digital stills give you exceptional resolution and zoom capabilities," Rowe added.

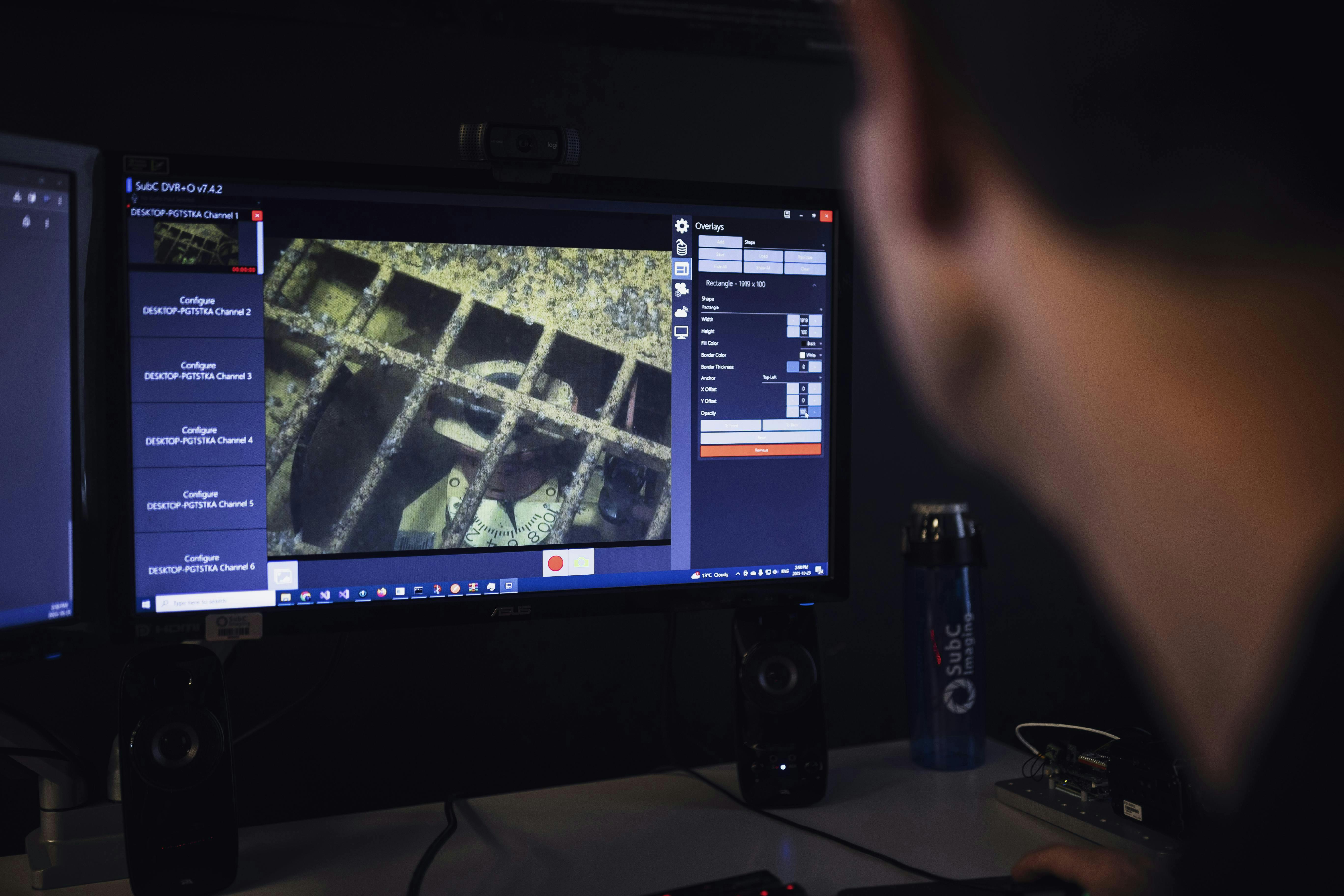

SubC has been evolving this imaging technology since 2017. In an effort to solve inspection challenges, SubC designed a new, optimized workflow and created this complete end-to-end single-channel live inspection suite. The specifications include a single interface for controlling cameras, lights and lasers, real-time topside media and data transfer, automatic organization of data, and features like Rayfin RDI with adjustable capture rates up to 2 Hz for improved inspection speed and accuracy. The technology offers overlays and annotations on the live and recorded video as well as voiceover capabilities.

Offshore energy case study

SubC integrated its real-time streaming and audio rooms technology with Fugro systems to successfully conduct what it says is the world's first fully remote inspection of offshore wind farm assets. The inspection took place in the North Sea in late 2023.

SubC delivered low-latency video, audio and data transmission crucial for the remote piloting of the Fugro USV and eROV. The technology ensured operators experienced real-time control, fostering an immediate connection with the site. Additionally, SubC's technology offered a reliable online connection, virtually eliminating dropouts for uninterrupted data streaming during inspections. The distributed accessibility of the technology enabled multiple teams in different locations to monitor the live data stream simultaneously, contributing to the collaborative success of the project by ensuring all stakeholders had access to critical information.

About the Author

Ariana Hurtado

Editor-in-Chief

With more than a decade of copy editing, project management and journalism experience, Ariana Hurtado is a seasoned managing editor born and raised in the energy capital of the world—Houston, Texas. She currently serves as editor-in-chief of Offshore, overseeing the editorial team, its content and the brand's growth from a digital perspective.

Utilizing her editorial expertise, she manages digital media for the Offshore team. She also helps create and oversee new special industry reports and revolutionizes existing supplements, while also contributing content to Offshore's magazine, newsletters and website as a copy editor and writer.

Prior to her current role, she served as Offshore's editor and director of special reports from April 2022 to December 2024. Before joining Offshore, she served as senior managing editor of publications with Hart Energy. Prior to her nearly nine years with Hart, she worked on the copy desk as a news editor at the Houston Chronicle.

She graduated magna cum laude with a bachelor's degree in journalism from the University of Houston.