Editor's note: This Subsea Systems column first appeared in the September-October 2023 issue of Offshore magazine. Click here to view the full issue.

By Ariana Hurtado, Editor and Director of Special Reports

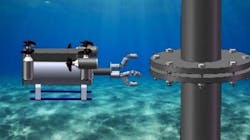

Companies utilize a variety of robotics offshore for subsea inspection, such as ROVs and AUVs, and artificial intelligence (AI) and automation play a large role in these technological innovations. AI and automation have improved subsea robotics by enhancing autonomous navigation, monitoring, detection and inspection.

For instance, DeepOcean in recent years has developed its Autonomous Inspection Drone (AID). The intelligent observation-class ROV is capable of performing programmed inspections of subsea assets. The AID project is a partnership between DeepOcean, Argus Remote Systems and Vaarst, where a system of systems has been developed with industry guidance, support and funding from AkerBP to bring a platform to market.

The AID is based on a Rover MK2 ROV from Argus Remote Systems. Argus is also responsible for AID platform and navigation algorithm. DeepOcean is responsible for the digital twin platform, mission planner software and live view of the AID in operation, while Vaarst is responsible for the machine vision camera for autonomous navigation and data collection. The AID can operate in water depths down to 3,000 m.

The AID was mobilized in February on board the Edda Fauna subsea IMR and ROV support vessel for its first offshore operations, at one of DeepOcean’s annual inspection campaigns for an operator on the Norwegian Continental Shelf. Remota AS, the joint venture between DeepOcean, Solstad Offshore and Østensjø Group, is enabling offshore operations to be performed from onshore through digitalized control systems. DeepOcean is running the AID from the Remota control center.

In the AUV category, Saipem is taking advantage of AI's benefits with its FlatFish technology, which features an advanced AI-based control system capable of goal-driven autonomous mission execution with real-time decision-making.

Earlier this summer, Petrobras commissioned Saipem to develop and test an autonomous subsea inspection robot offshore Brazil. This will be based on Saipem’s fleet of underwater drones, initially focused on the Flatfish AUV. The program will include qualification of associated autonomous drone-based services, with future inspection contract options. Operators can use Saipem’s FlatFish technology to assist them during the life of complex subsea fields and efficiently manage related operational risks. FlatFish is the conjunction between the subsea robotics program of Shell (with research institute Senai Cimatec) and Saipem’s Hydrone program.

R&D efforts

University of Houston (UH) researchers are developing an autonomous robot to identify potential pipeline leaks and structural failures during subsea inspections. Researchers at the UH College of Mechanical Engineering said in late August that the technology will be designed to make the inspection process safer and more cost effective, while also protecting subsea environments from disaster. The SmartTouch technology now in development at UH consists of ROVs equipped with multiple stress wave-based smart touch sensors, video cameras and scanning sonars that can swim along a subsea pipeline to inspect flange bolts.

The Bureau of Safety and Environmental Enforcement is funding the project with a $960,493 grant to UH researchers. The UH researchers are collaborating with Oceaneering on the project, and Chevron will evaluate the technology’s future commercialization.

The SmartTouch sensing technology is expected to open the doors for inspection of other kinds of subsea structures, according to the researchers, by forming a design template for future robotic technologies.

There's a clear benefit to incorporating AI and autonomous systems in the subsea inspection process, and the technological innovations are surely to continue to evolve over the coming years.

About the Author

Ariana Hurtado

Editor-in-Chief

With more than a decade of copy editing, project management and journalism experience, Ariana Hurtado is a seasoned managing editor born and raised in the energy capital of the world—Houston, Texas. She currently serves as editor-in-chief of Offshore, overseeing the editorial team, its content and the brand's growth from a digital perspective.

Utilizing her editorial expertise, she manages digital media for the Offshore team. She also helps create and oversee new special industry reports and revolutionizes existing supplements, while also contributing content to Offshore's magazine, newsletters and website as a copy editor and writer.

Prior to her current role, she served as Offshore's editor and director of special reports from April 2022 to December 2024. Before joining Offshore, she served as senior managing editor of publications with Hart Energy. Prior to her nearly nine years with Hart, she worked on the copy desk as a news editor at the Houston Chronicle.

She graduated magna cum laude with a bachelor's degree in journalism from the University of Houston.